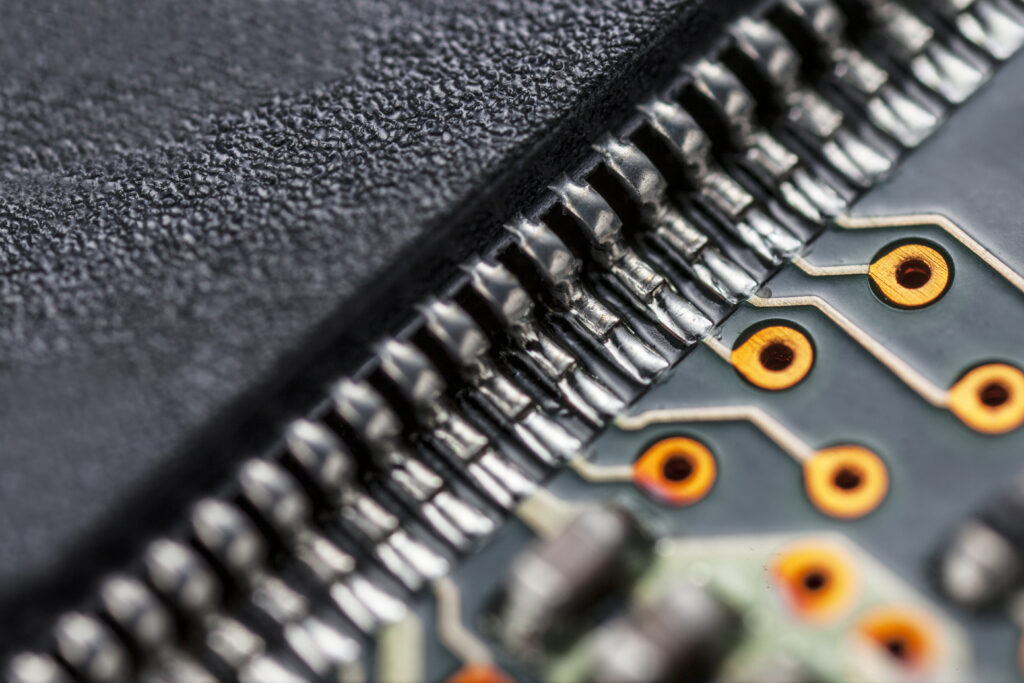

Wave & Selective soldering fluxes

THT-components, connectors, switches and power semiconductors are commonly soldered through wave soldering processes. Our Ecofrec™ fluxes ensure great wetting properties, optimize on solder flow and achieve high-reliability solder joints.

Connectors, switches and power semiconductors are usually soldered on PCBA’s through selective soldering processes. EcofrecTM flux innovations ensure great wetting properties, optimize on solder flow and achieve high-reliability solder joints. Adapted solutions are available for different selective-soldering needs including alcohol or the more environmental friendly waterbased formulations.

Adapted solutions are available for different soldering needs including alcohol or the more environmental friendly water based (100% no VOC) formulations.

Read morePRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don`t find a specific product, you will probably find it with our search option.

Showing all 9 results

-

ECOFREC 205

- Solvent based no-clean liquid flux

- Wave & selective soldering

- Excellent wetting on all board finishes

-

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

-

ECOFREC 303

- Waterbased VOC free, no-clean liquid flux

- Soldering either with air or nitrogen controlled atmosphere

- High reliability

-

ECOFREC CMA 155

- Solvent based high rosin liquid flux

- Suitable for all fluxing processes

- Very good wetting & easy to clean

-

ECOFREC DD6

- Solvent based rosin liquid flux

- Wave -, selective spray, foam or manual brush process

- high reliability & easy to clean

-

ECOFREC HT504

- Solvent based, no-clean rosin liquid flux

- Dipping or manual brush process

- High temperature soldering & easy to clean

-

ECOFREC 202

- Solvent based no-clean liquid flux

- Wave & selective soldering

- High reliability and no visual residues

-

ECOFREC DILUENT 1

- Flux thinner for solvent based fluxes.

- Adjust density due to evaporation.

- Made from high purity solvents.