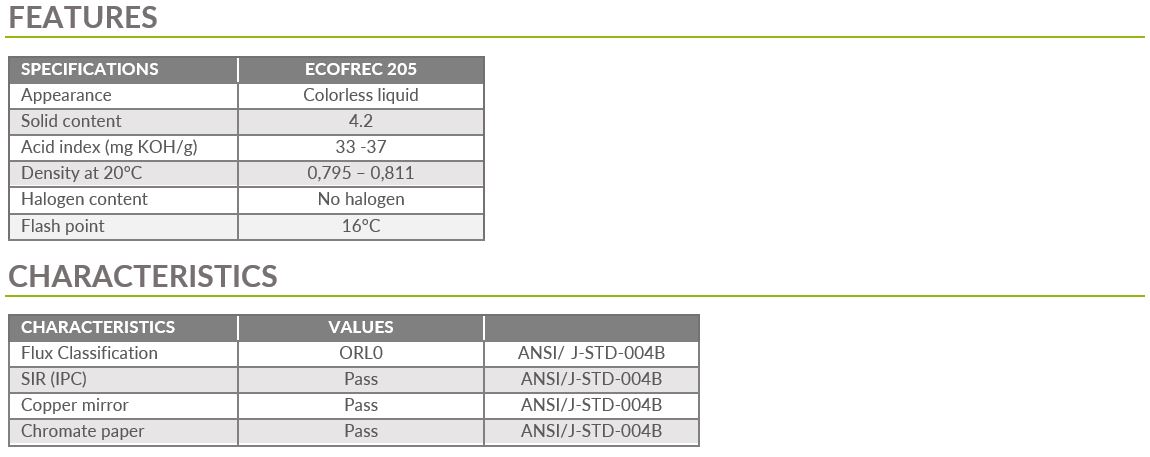

ECOFREC 205

Solvent based with best wetting properties

- Solvent based no-clean liquid flux

- Wave & selective soldering

- Excellent wetting on all board finishes

ECOFREC 205

Is based on our new generation solder flux technology, developed to provide best wetting properties regardless of the selected board finishes. Excellent soldering results within lead-free as well as leaded wave- and selective soldering processes are achieved.

It’s a no clean alcohol based flux recommended for soldering either with air or nitrogen controlled atmosphere.

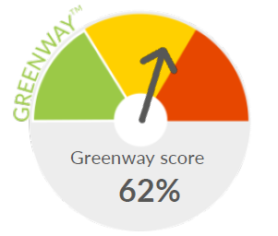

This is not a product

Although fully in line with safety & environmental regulations, this product doesn`t match our strict criteria to be labelled as a Greenway product.

LOOKING FOR A MORE SUSTAINABLE SOLUTION?

GREENWAY ALTERNATIVE

Discover more about Greenway

Benefits

PERFORMANCE

- Excellent wetting & through-hole filling

- Great performance for Ni/Au, Sn, Ag, HAL and OSP PCB finishes

- Exceptionally low levels of solder-ball formation

- High SIR values and passes BONO corrosion test

COST

- Helps to avoid pre-mature failures of your electronic assembly

- No flux residue cleaning required

- Highest grade alcohol formula, providing a consistent & reliable process

HSE

- Free of CMR containing substances

- Free of halide (Fluoride, Chloride, Bromide) and halogen

Process Recommendation

The best process will depend on factors such as operating conditions, equipment, board or component design. Check our product datasheet for info on process recommendations. In any case, our team is ready to advise and assist you in the implementation of our products.