SMT Solder Pastes

Our dedicated offer of solder pastes for the SMT process, combining different alloys, powder size and flux media for printing, dispensing and assemblies.

Solder Paste Solutions

for Every SMT Challenge

Solder paste plays a vital role in the SMT process by ensuring strong electrical and mechanical connections between components and PCBs, with its quality and formulation directly impacting manufacturing efficiency, reliability, and overall product performance.

Select subsegment :

High Reliability Solder Paste

Due to the demanding requirements of high-reliability electronics such as long-term durability, chemical and mechanical resilience, and environmental compliance INVENTEC has pioneered advanced solder solutions featuring halogen-free formulations, highly inert flux residues, and robust lead-free alloys tailored for extreme operating conditions.

In applications where long-term reliability and safety are paramount, such as life-critical or harsh-environment electronics, advanced SMT solder pastes ensure dependable performance beyond what conventional solutions can achieve…

Learn more

Jet Printing & Dispensing Solder Paste

Jet printing and dispensing solder pastes are essential for precise and flexible SMT manufacturing, and INVENTEC’s specially formulated pastes ensure consistent, high-quality deposits with optimized flow and cleaning properties, compatible with leading equipment like Mycronic, Vermes, Essemtec, and Musashi.

Advanced jet printing solder paste and dispensing solder paste solutions optimized for high-performance jet dispensing and dispensing systems, ensuring precision, reliability, and flexibility in modern electronic assembly…

Learn more

Low & No Silver Solder Paste

Low-silver solder pastes and no-silver solder pastes are essential in SMT applications; INVENTEC offers these advanced solutions to help manufacturers reduce material costs, improve solder joint reliability, and minimize the risk of corrosion, all while ensuring consistent, high-quality performance across demanding electronic assembly processes.

Low-silver solder pastes and no-silver solder pastes offer high-performance, corrosion-resistant alternatives to traditional silver solder paste, helping manufacturers reduce costs while improving reliability and drop shock resistance in demanding SMT applications…

Learn more

Low Temperature Solder Paste

Low temperature solder paste, offered by INVENTEC, plays a crucial role in SMT (Surface Mount Technology) applications by enabling reliable soldering of temperature-sensitive components, minimizing the risk of thermal damage, and supporting more efficient, cost-effective, and sustainable manufacturing processes.

Low temperature solder paste is revolutionizing electronics manufacturing by combining energy savings, design flexibility, and enhanced reliability into a cooler, greener, and more efficient alternative to traditional soldering methods…

Learn more

Low Voiding Solder Paste

Low voiding solder paste, such as those developed by INVENTEC, plays a key role in SMT (Surface Mount Technology) by minimizing air pockets during reflow, ensuring reliable electrical connections, and enhancing the long-term performance and durability of electronic assemblies.

To ensure high reliability in applications like automotive, power electronics, and LED lighting, selecting a low voiding solder paste is essential, as it minimizes void formation, enhances thermal and electrical performance, and strengthens solder joint integrity…

Learn more

Miniaturization Solder Paste Solutions

Miniaturized solder paste solutions are vital in SMT, with INVENTEC offering advanced formulations that enable precise application for smaller components, ensuring reliable, high-quality connections even in the most compact and high-density electronic devices, meeting the demands of modern technology.

As the electronics industry advances, the demand for high-performance SMT solder paste solutions is rising to meet the challenges of ongoing miniaturization and increasingly compact miniature electronic devices…

Learn more

Robust Assembly Solder Paste

High Volume PCB Assembly Solder Paste plays a critical role in ensuring consistent and reliable solder joints during high-speed surface mount technology (SMT) processes, enabling efficient, precise, and high-quality mass production of electronic devices—solutions that INVENTEC proudly delivers with proven expertise.

Discover how our robust SMT solder paste solutions are engineered to enhance process stability, ensure repeatable performance, and maximize production efficiency in demanding high volume PCB assembly environments…

Learn more

Water-Soluble Solder Paste

Water-soluble solder paste is necessary in SMT (Surface Mount Technology) applications as it ensures efficient soldering with minimal residue, allowing for easier post-reflow cleaning and improved overall board reliability, with INVENTEC offering advanced solutions to meet these needs.

ECOREL™ water-soluble solder pastes offer high reliability, exceptional wetting properties, and easy cleaning for lead-free soldering and SMT printing, ensuring optimal performance and efficiency in electronic assembly…

Learn more

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

Do you need cleaning or coating after soldering? We provide FREE-OF-CHARGE cleaning or coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. It is also possible to attend trials in person.

SMT Solder Pastes Guide: Boosting Performance and Reliability

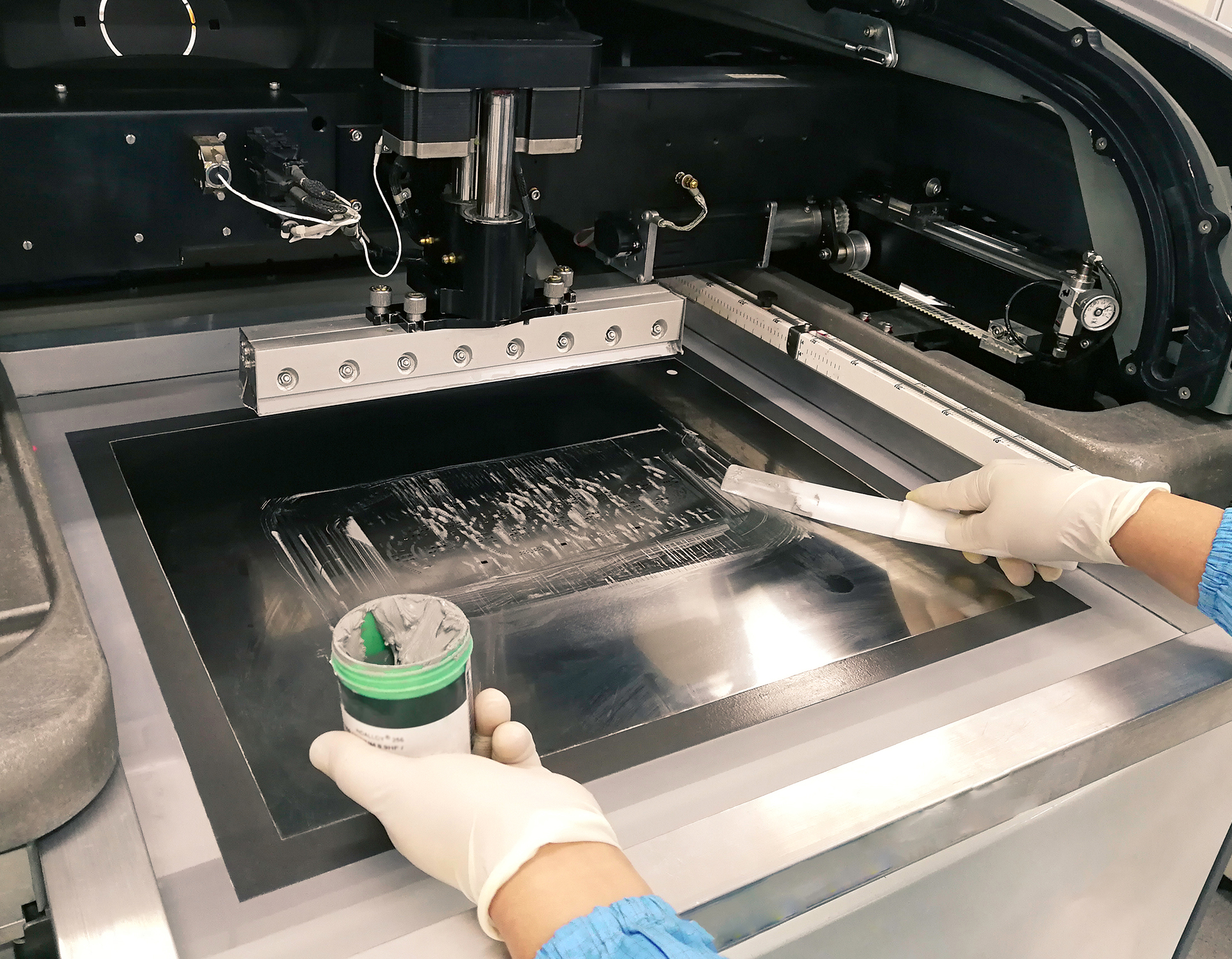

Solder paste is a critical material used in the SMT process (Surface Mount Technology), acting as the bonding agent between surface-mounted components and printed circuit boards (PCBs). Modern electronics manufacturing relies heavily on high-performance solder pastes to ensure optimal conductivity, mechanical strength, and reliability. Whether for consumer electronics, automotive control systems, or medical devices, choosing the right solder paste can dramatically affect the efficiency and yield of the SMT production line. Advanced solder pastes are engineered for consistent printing, excellent wetting, and minimal residue, making them essential for today’s high-density and fine-pitch PCB assemblies.

In the SMT process, solder paste is applied to the PCB using stencil printing techniques, followed by precise component placement and reflow soldering. The quality and formulation of the solder paste directly influence reflow profiles, solder joint integrity, and overall process stability. Manufacturers often choose solder pastes based on alloy composition, flux type, and specific application needs—whether leaded or lead-free. As SMT technology continues to evolve, the demand for innovative solder pastes that deliver superior performance, reduced defects, and high reliability is growing rapidly. Optimizing your SMT process with the right solder paste is key to staying competitive in today’s fast-paced electronics market.

Automotive SMT Solder Pastes for High-Reliability Applications

In the automotive sector, solder paste quality directly impacts the reliability of electronic control units (ECUs), infotainment systems, and safety-critical components. The SMT process for automotive electronics requires solder pastes capable of withstanding thermal cycling, humidity, and vibration. Low-voiding solder paste options and lead-free alloys are commonly used to meet automotive-grade standards and ensure long-term electrical and mechanical integrity.

Aerospace and Defense SMT Solder Paste Performance

Aerospace and defense applications require solder pastes with unmatched durability, precision, and compliance with stringent military and aerospace regulations. The SMT process for avionics, radar systems, and satellite electronics must use high-purity solder paste to ensure zero-defect soldering in high-altitude and high-stress environments. Specialized solder pastes with high-temperature resistance and excellent print stability are critical for meeting these demanding specifications.

Medical SMT Solder Pastes for Precision Electronics

In the medical electronics field, solder paste performance is essential for ensuring the reliability and safety of diagnostic equipment, implantable devices, and patient monitoring systems. The SMT process in medical device manufacturing prioritizes cleanliness, biocompatibility, and long-term functionality. Using ultra-clean, low-residue solder pastes supports stringent regulatory compliance and contributes to the production of life-saving technology with uncompromised quality.

Read more

Interview with Mélanie Mathon, R&D Manager at INVENTEC – APEX EXPO IPC 2025

From enhanced performance in fine-pitch applications to environmentally responsible formulations, Mélanie Mathon, R&D Manager Soldering & Coating, discusses how INVENTEC is pushing the boundaries of SMT solder paste development. Learn how cutting-edge R&D is shaping the future of soldering processes and why selecting the right SMT solder paste is critical for reliability and efficiency in electronics manufacturing.