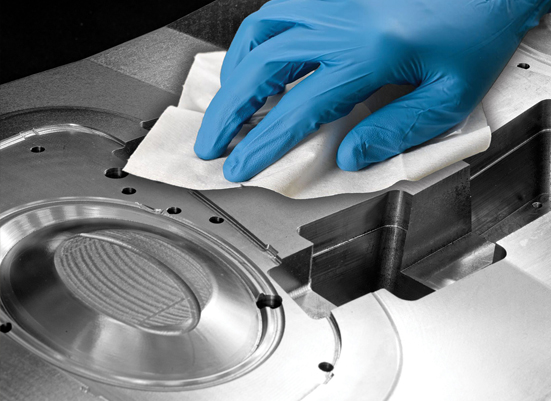

Degreasing

Oil & Grease removal from various metals and alloys including very sensitive ones. Our products are qualified in high demanding industries like Aerospace, Automotive and Medical and go beyond today’s environmental regulations.

Degreasing Solutions to Overcome Every Oil and Grease Removal Challenge

Effective degreasing solutions are critical for tackling tough oil and grease removal on metal components, ensuring optimal cleanliness that boosts manufacturing reliability, operational efficiency, and overall product performance.

Select subsegment :

Oil Removal

Oil removal enhances mechanical reliability by preventing buildup in automotive engines, protecting metals and alloys from corrosion in aerospace components, and, with solutions provided by INVENTEC, ensures the sterility of medical equipment for safe and efficient operations across these industries.

Discover advanced oil removal solutions designed for various metal components, offering safe, efficient, and tailored metal cleaning processes to ensure optimal surface quality and production reliability…

Learn more

Grease Removal

Grease removal in the automotive, aerospace, and medical industries enhances performance, safety, and longevity by preventing component wear, and INVENTEC offers innovative solutions designed to ensure smooth operation, improve efficiency, and maintain clean, functional surfaces for critical systems and machinery.

Discover expert solutions for grease removal and metal degreasing that ensure efficient, safe, and environmentally friendly cleaning of all types of metal components…

Learn more

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.

Industrial Degreasing Guide

for Optimal Metal Cleaning Efficiency

In modern industrial operations, grease removal and oil removal are critical for maintaining the performance and longevity of machinery and components. The degreasing process plays a vital role in preparing metal components by ensuring thorough metal degreasing and metal cleaning. Companies rely heavily on a high-performance metal cleaner and degreaser to degrease metal surfaces and guarantee the proper adhesion of coatings, improved conductivity, and extended equipment lifespan. Efficiently removing oil and grease helps prevent contamination and supports quality control in all phases of production.

Whether you’re degreasing metal for finishing, assembling, or packaging, an effective metal degreasing method ensures consistency and safety. The right metal cleaner and degreaser allows industries to degrease metal and remove oil quickly and efficiently, even from complex metal components. A reliable degreasing process tailored to industrial needs ensures comprehensive oil removal and grease removal from every surface, making it a cornerstone of effective metal cleaning in any manufacturing or maintenance environment.

Automotive Excellence: Clean Engines Start with Clean Parts

In the automotive industry, metal degreasing is crucial for performance and reliability. Whether during engine assembly or transmission maintenance, thorough grease removal and oil removal are mandatory. Automotive manufacturers depend on powerful metal cleaner and degreaser solutions for degreasing metal components like gearboxes, pistons, and engine blocks. Efficiently removing oil and grease ensures that lubricants, coatings, and paints bond correctly, while preventing mechanical failure. With the right degreasing process, automotive plants can degrease metal parts fast and at scale.

Aerospace & Defense: Precision Through Cleanliness

In aerospace and defense, even microscopic traces of grease or oil can compromise mission-critical systems. That’s why metal cleaning, grease removal, and oil removal are paramount in this sector. Complex metal components like turbines, landing gear, and structural elements require specialized metal cleaner and degreaser products to achieve flawless metal degreasing. A robust degreasing process ensures that every part meets strict regulatory standards. By degreasing metal accurately, the aerospace and defense industries ensure safety, performance, and compliance.

Medical Grade Clean: Sterile Surfaces Every Time

In the medical field, precision and hygiene are inseparable. Metal degreasing is essential for surgical tools, implants, and diagnostic equipment. Effective oil removal and grease removal are not just preferred—they’re mandatory. Using a medical-grade metal cleaner and degreaser, manufacturers can ensure all metal components are sterile and fully degreased. The degreasing process must eliminate all residues without leaving harmful chemicals behind. For hospitals and medical device makers, degreasing metal to perfection supports both patient safety and regulatory compliance.

Read more