High Reliability

CHEMICAL RELIABILITY

Most no-clean flux residues after reflow are chemically inert to only some extend and cleaning or in other words, defluxing is an option still not always desired.

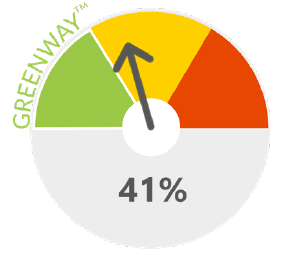

Inventec targeted from the early days high reliability applications. We were one of the first companies providing halogen-free formulations and to use BONO test to confirm the reliability of our solder products. This allowed us to fine-tune over those years well balanced solder solutions with highly inert flux residues.

MECHANICAL RELIABILITY

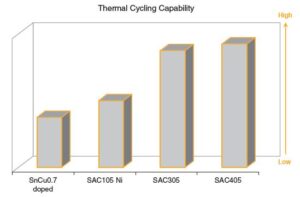

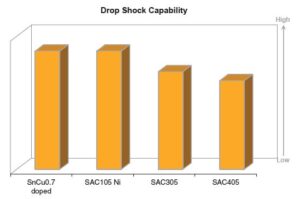

The strength of the solder joint is defined by the mechanical reliability properties of the alloy. Some electronic assemblies have to deal with fast and extreme temperature changes, high temperatures, vibrations or need some resistance to drops. Choosing the right alloys for a particular need is key.

In the past, leaded alloys where the solution to electronic assemblies exposed to extreme temperature changes but due to environmental concerns they have been prohibited to use (with a few exceptions). Lead free alternatives, like SAC405, SAC378 and other variations have been introduced over the years. Inventec’s R&D team is constantly looking for improvements in this field.

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don`t find a specific product, you will probably find it with our search option.

Read moreShowing all 11 results

-

ECOREL FREE 305-21

- SAC305 lead free solder paste

- No clean SMT printing & dispensing process

- High reliability applications

-

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

-

-

-

ECOREL EASY SPA-15

- SnPbAg leaded solder paste

- No clean SMT printing process

- Excellent performance for ultrafine-pitch

-

-

ECOREL EASY 802M2

- Sn62Pb36Ag2 leaded solder paste in Type 3

- No clean SMT printing process

- Robust assembly

-

ECOREL EASY 802M T4

- Sn62Pb36Ag2 leaded solder paste in Type 4

- No clean SMT printing process

- Robust assembly

-

-