Polishing Compounds Removal

Solutions for difficult to remove substances like polishing paste, diamond polishing liquid, polymers & resins without harming the substrates they have to removed from. Suited for your desired process and formulated to meet today’s environmental regulations and beyond.

Polishing Compounds Removal Solutions for Every Surface Finishing Challenge

Effective removal of polishing compounds is critical to prevent surface contamination, ensure optimal adhesion, and maintain the integrity and performance of high-precision components across advanced manufacturing processes.

Select subsegment :

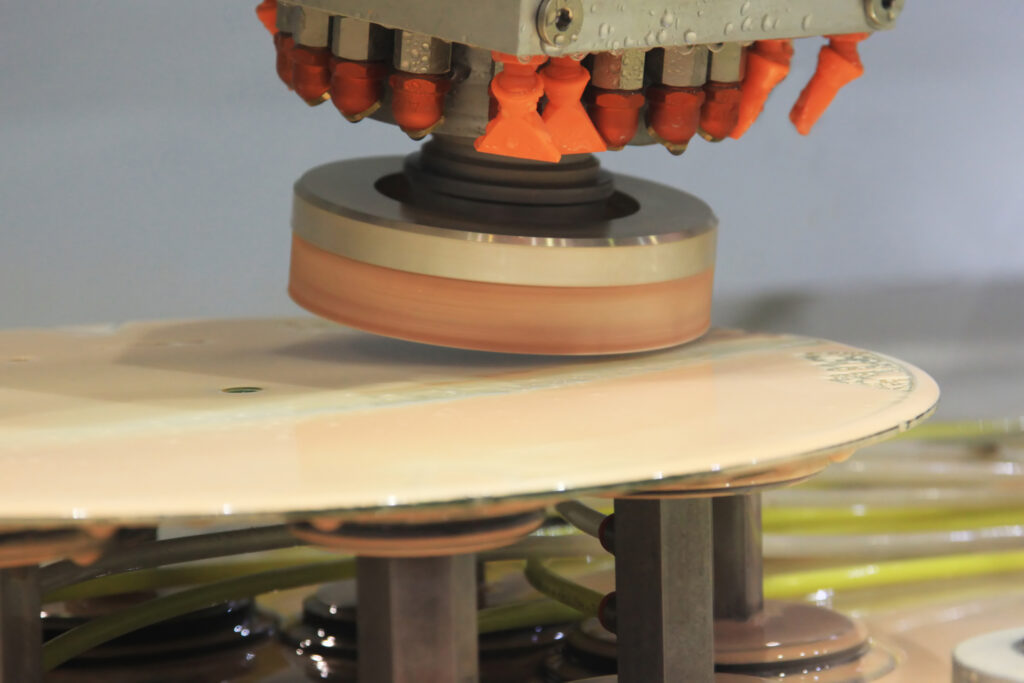

Liquid Diamond Polish Removal

The cleaning of liquid diamond polish is essential in industries to maintain optimal tool performance, prevent material buildup, and ensure the accuracy and finish of precision surfaces; challenges for which INVENTEC provides advanced, high-efficiency cleaning solutions designed for demanding industrial applications.

Removing stubborn residues of liquid diamond polish and other diamond polishing compounds from precision-machined parts is a critical challenge that demands advanced, high-performance cleaning solutions…

Learn more

Polishing Paste Removal

The cleaning of polishing paste in industries is important to ensure the removal of contaminants, enhance product quality, and maintain the efficiency and longevity of equipment used in polishing and finishing operations; INVENTEC offers effective cleaning solutions tailored to meet these industrial requirements.

Effectively removing stubborn polishing paste and polishing compounds demands customized cleaning solutions that protect sensitive alloys, prevent corrosion, and deliver superior removal of polish residue for optimal part quality and performance…

Learn more

Polymer & Resin Removal

Removing polymer and resin residues is crucial in many industrial processes to ensure product quality, operational reliability, and optimal performance. INVENTEC offers specialized solutions designed to meet these critical cleaning needs, helping manufacturers maintain high standards across diverse applications.

Discover safe, effective, and environmentally responsible solutions for resin and polymer residue removal, using advanced compound removers designed for industrial applications while ensuring compatibility and sustainability…

Learn mores

Wax Removal

The cleaning of wax in electronics and precision manufacturing is important to prevent contamination that can impact the performance, reliability, and lifespan of delicate components; challenges that INVENTEC helps solve with specialized, high-performance cleaning solutions tailored for demanding industrial environments.

Effective wax removal is essential in industrial cleaning processes, and INVENTEC offers advanced wax removers and compound removers tailored to ensure flawless cleaning of delicate and complex components across various cleaning methods…

Learn more

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.

Polishing Compounds Removal Guide

In industrial manufacturing, the efficient polishing compounds removal process is essential to ensure product performance, cleanliness, and precision. The use of advanced compound remover solutions helps eliminate residues from polishing compounds, including polishing paste, diamond polishing paste, and other abrasive materials. Whether it’s for wax removal or resin removal, choosing the right cleaning technology ensures surfaces are perfectly prepped for finishing, bonding, or inspection.

High-quality compound remover products are designed to break down stubborn polishing paste and diamond polishing paste on metal, plastic, or composite surfaces. Efficient polishing compounds removal is critical in environments requiring flawless finishes and absolute cleanliness. These removers are used in both manual cleaning and automated systems, delivering consistent results across high-throughput production lines. In addition to enabling smooth downstream processes, thorough wax removal and resin removal help extend equipment life by preventing buildup. As industrial standards tighten, manufacturers in sectors like automotive, aerospace & defense, and medical increasingly rely on advanced compound remover solutions to meet both functional and regulatory expectations.

Automotive – Performance Starts with Clean Surfaces

In the automotive industry, effective polishing compounds removal ensures that painted and metallic parts are free of contaminants. The use of a reliable compound remover is crucial for removing polishing paste and diamond polishing paste from engine components, body panels, and trim. Thorough wax removal and resin removal allow for optimal adhesion in coatings, improving durability and aesthetics.

Aerospace & Defense – Clean Components for Critical Missions

In aerospace & defense, the demand for surface precision is non-negotiable. Effective polishing compounds removal eliminates every trace of polishing paste and diamond polishing paste used in part finishing. Specialized compound remover solutions ensure complete wax removal and resin removal from sensitive components like turbine blades and radar parts, ensuring compliance with strict industry standards.

Medical – Safe, Sterile, Spotless

In the medical field, cleanliness is a critical safety factor. The thorough polishing compounds removal of surgical instruments, implants, and devices is achieved using high-grade compound remover solutions. These cleaners are specifically formulated for removing diamond polishing paste, polishing paste, and stubborn resin residues. Complete wax removal ensures biocompatibility and prevents contamination in sterile environments.

Read more