3M NOVEC 7100

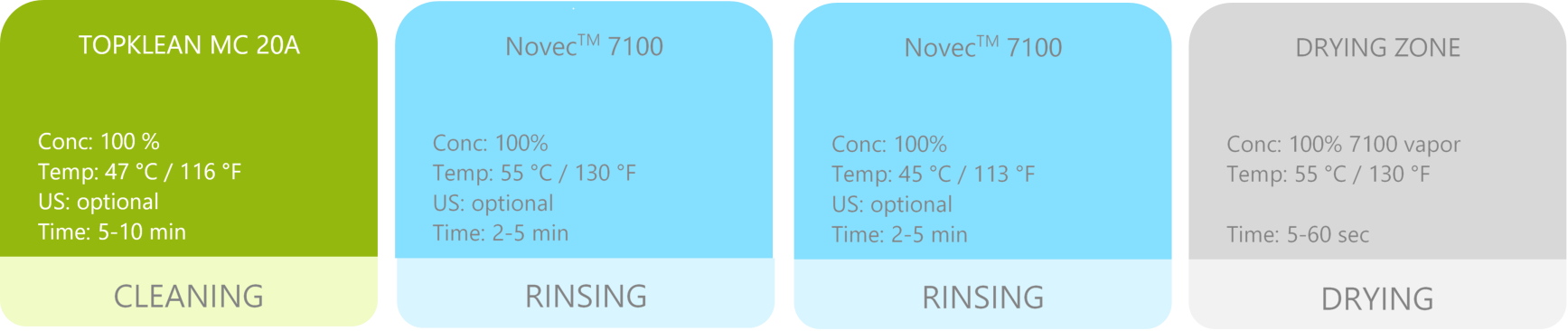

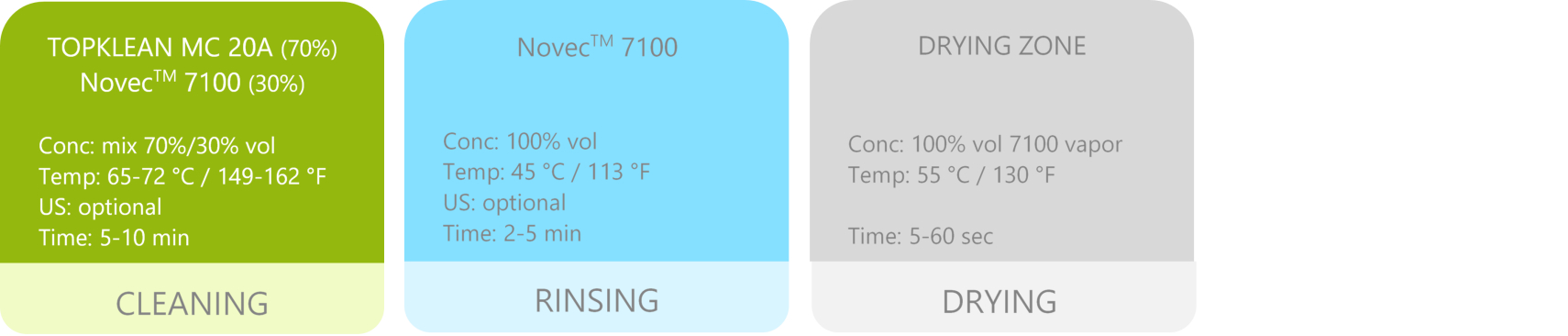

- Light oil & particles removal / rinsing & spotless fast drying

- Vapor phase, co-solvent, flushing & drying process

- Very low surface tension

IMPORTANT NOTICE: PHASE-OUT 3M™ PRODUCTS

If you want to know more about the 3M™ products phase-out, click on the this link.

OUR ALTERNATIVE(S):

- PROMOSOLV DR3 -> Same formulation

- PROMOSOLV NEO A1 -> Similar properties & applications + NO GWP & PFAS FREE

3M Novec 7100

3M Novec 7100 Engineered Fluid, methoxy-nonafluorobutane (C4F9OCH3), is a clear, colorless and low-odor fluid intended to replace ozone-depleting substances (ODSs) and compounds with high global warming potential (GWP) in many applications.

The high boiling point and low surface tension of Novec 7100 fluid make it ideal for use in vapor degreasing applications as a neat (pure), azeotropic component or co-solvent parts cleaner. In addition, its chemical and thermal stability, non-flammability and low toxicity make it useful for many other industrial and specialty solvent applications.

Letter from 3M – Inventec authorized distributor for EMEA area

Request a sample

for "3M NOVEC 7100"

This is a product valuable for our ECOPROGRAM

Products valuable for our ECOPROGRAM can be returned to us for recycling (depending on location).

- Avoid adding waste into the environment

- Avoid destruction cost

- Buy recycled products at a lower cost.

Benefits

PERFORMANCE

- Thermal and chemical stable in use (azeotropic formulation)

- The very low surface tension allows deep rinsing of parts with complex geometry

- Short rinsing and drying times

COST

- Continuous recycling in equipment for a long bath-life

- Can be returned for recycling and re-use

- The relative high boiling point reduces risk of solvent drag, so limiting consumption

HSE

- Very low toxicity (refer to the SDS)

- No Ozon Depletion Potential (ODP) & low Global Warming Potential (GDP)

- Non-flammable

Applications

DRYING OF SEMICONDUCTOR WAFERS

Novec™ 7100 or Novec™ 71IPA are used as a drying agent for semiconductor wafers as a drop-in alternative to IPA.