Degreasing

Oil & Grease removal from various metals and alloys including very sensitive ones. Our products are qualified in high demanding industries like Aerospace, Automotive and Medical and go beyond today’s environmental regulations.

Select subsegment :

Oil Removal

Oil removal enhances mechanical reliability by preventing buildup in automotive engines, protecting metals and alloys from corrosion in aerospace components, and ensuring the sterility of medical equipment for safe and efficient operations across these industries.

Each oil has properties that characterize it. Each oil removal process must therefore take into account the particularity of each of the oils to be removed. Whole, soluble, additive oils require adequate knowledge and methodology to achieve an oil removal that is consistent with the required level.

It’s obvious that the part to clean cannot be damaged, not even on a microscopic level, so when using a detergent, compatibility with metals & alloys is something to pay attention to. On the other hand, when performing oil removal with solvents, certain plastics may not be compatible. A temporary protection against corrosion between production steps could also be required.

INVENTEC has cleaning formulations with a corrosion inhibitor included, avoiding an extra step in your oil removal process. Faced with all these constraints, INVENTEC has developed several products to provide an adequate solution, suited to your desired oil removal process.

INVENTEC can help you with

The tables below give an overview of the different oil types and which product we recommend according to your desired oil removal process.

OIL REMOVAL

| Type of Pollutant | Type of Process | Product Solution |

|---|---|---|

| Hydrocarbon Oil | Co-Solvent |

|

| Mono-Solvent (Vapor Phase) |

|

|

| Vacuum |

|

|

| Aqueous Spray |

|

|

| Aqueous Immersion |

|

|

| Manual Cleaning |

|

|

| Water Soluble Oil | Co-Solvent | Not Recommended Process |

| Mono-Solvent (Vapor Phase) | Not Recommended Process | |

| Vacuum | Not Recommended Process | |

| Aqueous Spray |

|

|

|

WITH AEROSPACE HOMOLOGATION: |

||

| Aqueous Immersion |

|

|

| Manual Cleaning |

|

|

| Silicon Oil | Co-Solvent |

|

OIL REMOVAL + TEMPORARY CORROSION PROTECTION

| Type of Pollutant | Type of Process | Product Solution |

|---|---|---|

| Hydrocarbon Oil | Co-Solvent | No Corrosion Risk Due to Absence of Water in Cleaning Process |

| Mono-Solvent (Vapor Phase) | No Corrosion Risk Due to Absence of Water in Cleaning Process | |

| Vacuum | No Corrosion Risk Due to Absence of Water in Cleaning Process | |

| Aqueous Spray |

|

|

| Aqueous Immersion |

|

|

| Manual Cleaning |

|

|

| Water Soluble Oil | Co-Solvent | Not Recommended Process |

| Mono-Solvent (Vapor Phase) | Not Recommended Process | |

| Vacuum | Not Recommended Process | |

| Aqueous Spray |

|

|

| Aqueous Immersion |

|

|

| Manual Cleaning |

|

Above table is a non exhaustive list. INVENTEC offers more products which could be older and for which we have an improved formulation or a fine-tuning to a specific need. You may find a specific product via our search option or contact us for more information.

What are the different processes?

- Co-solvent: solvent process with Topklean products as cleaning agent and Hydrofluoroethers as rinsing solvent

- Mono-solvent: vapor phase cleaning with 1 single solvent for cleaning & rinsing

- Aqueous spray: spray in air / spray in line / immersion jets / water based flushing

- Aqueous Immersion : immersion in tank with options for heating, ultrasonics, agitation (moving of cleaning baskets)

- Manual cleaning: spray, poor or dip in simple tank without heating

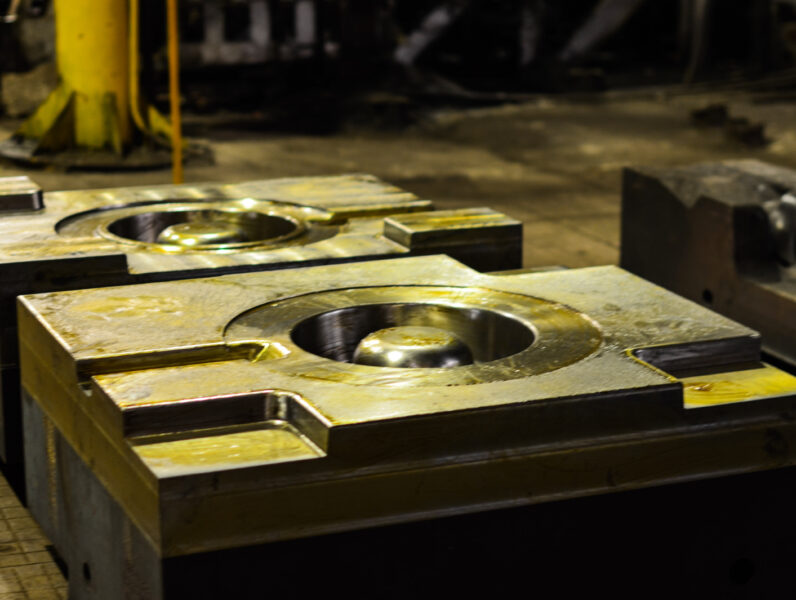

Grease Removal

Grease removal in the automotive, aerospace, and medical industries enhances performance, safety, and longevity by preventing component wear, ensuring smooth operation, and maintaining clean, functional surfaces for critical systems and machinery.

The complexity of parts and the multiple grease types, makes choosing the right cleaning product an important factor in order to obtain an effective and quick cleaning process. When grease is cleaned manually, special attention is required with regards to safe use for the operators.

INVENTEC has developed several products suited to your desired process, grease type and to meet current environmental regulations and beyond.

The table below gives an overview of the different grease types and which product we recommend according to your desired process.

| Type of Pollutant | Type of Process | Product Solution |

|---|---|---|

| Grease on Ferrous Metals | Co-Solvent |

|

| Mono-Solvent (Vapor Phase) |

|

|

| Vacuum |

|

|

| Aqueous Spray |

|

|

| Aqueous Immersion |

|

|

| Manual Cleaning |

|

|

| Grease on Sensitive Metals

(Aluminium,…) |

Co-Solvent |

|

| Mono-Solvent (Vapor Phase) |

|

|

| Vacuum |

|

|

| Aqueous Spray |

|

|

| Aqueous Immersion |

|

|

| Manual Cleaning |

|

|

| Perfluorinated Greases | Mono-Solvent (Vapor Phase) |

|

Above table is a non exhaustive list. INVENTEC offers more products which could be older and for which we have an improved formulation or a fine-tuning to a specific need. You may find a specific product via our search option or contact us for more information.

What are the different processes?

- Co-solvent: solvent process with Topklean products as cleaning agent and Hydrofluoroethers as rinsing solvent

- Mono-solvent: vapor phase cleaning with 1 single solvent for cleaning & rinsing

- Aqueous spray: spray in air / spray in line / immersion jets / water based flushing

- Aqueous Immersion : immersion in tank with options for heating, ultrasonics, agitation (moving of cleaning baskets)

- Manual cleaning: spray, poor or dip in simple tank without heating

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.

Looking for another

cleaning solution ?

Search our entire cleaning range

You don’t find the

right product ?

Let’s discuss about your challenge

Industrial Degreasing Guide

for Optimal Metal Cleaning Efficiency

Whether you’re degreasing metal for finishing, assembling, or packaging, an effective metal degreasing method ensures consistency and safety. The right metal cleaner and degreaser allows industries to degrease metal and remove oil quickly and efficiently, even from complex metal components. A reliable degreasing process tailored to industrial needs ensures comprehensive oil removal and grease removal from every surface, making it a cornerstone of effective metal cleaning in any manufacturing or maintenance environment.

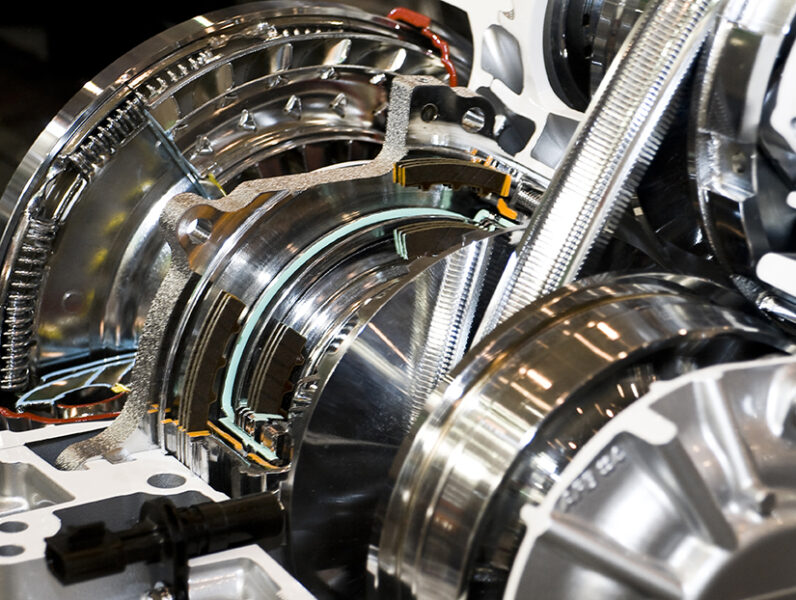

Automotive Excellence: Clean Engines Start with Clean Parts

In the automotive industry, metal degreasing is crucial for performance and reliability. Whether during engine assembly or transmission maintenance, thorough grease removal and oil removal are mandatory. Automotive manufacturers depend on powerful metal cleaner and degreaser solutions for degreasing metal components like gearboxes, pistons, and engine blocks. Efficiently removing oil and grease ensures that lubricants, coatings, and paints bond correctly, while preventing mechanical failure. With the right degreasing process, automotive plants can degrease metal parts fast and at scale.

Discover our Automotive Solutions by Segment

Aerospace & Defense: Precision Through Cleanliness

In aerospace and defense, even microscopic traces of grease or oil can compromise mission-critical systems. That’s why metal cleaning, grease removal, and oil removal are paramount in this sector. Complex metal components like turbines, landing gear, and structural elements require specialized metal cleaner and degreaser products to achieve flawless metal degreasing. A robust degreasing process ensures that every part meets strict regulatory standards. By degreasing metal accurately, the aerospace and defense industries ensure safety, performance, and compliance.

Discover our Aerospace & Defense Solutions by Segment

Medical Grade Clean: Sterile Surfaces Every Time

In the medical field, precision and hygiene are inseparable. Metal degreasing is essential for surgical tools, implants, and diagnostic equipment. Effective oil removal and grease removal are not just preferred—they’re mandatory. Using a medical-grade metal cleaner and degreaser, manufacturers can ensure all metal components are sterile and fully degreased. The degreasing process must eliminate all residues without leaving harmful chemicals behind. For hospitals and medical device makers, degreasing metal to perfection supports both patient safety and regulatory compliance.

Discover our Medical Solutions by Segment

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Read moreShowing all 15 results

-

PROMOCLEAN DISPER 22 ALU

- Removal of grease, heavy oils, burn-in residues & oxides

- Aqueous spray processes

- Compatible with most ferrous & non-ferrous alloys

-

PROMOCLEAN TP 125

- Removal of burnt residues, oxides, polishing pastes, heavy greases & oil

- Aqueous immersion process

- Compatible with ferrous alloys & copper

-

QUICKSOLV FIDES

- Oil & dust removal for dielectric cleaning

- For manual spray equipment

- Safe & fast cleaning under power

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

-

PROMOCLEAN DISPER 13

- Detergent with temporary protection for removing light oils on metallic parts

- Aqueous spray, flush & immersed jets processes

- General cleaner for light contaminations

-

BLUE GOLD

- Degreasing & particle removal from equipment in contact with oxygen

- Aqueous spray & immersion process

- Passes ASTM F-495 and ARP 1775A norm

-

PROMOCLEAN DISPER 11

- Detergent with temporary protection for removing light oils on metallic parts

- Aqueous spray, flush & immersed jets processes

- Compatible with a wide range of metals

-

PROMOCLEAN DISPER 3

- Detergent for removing hydrocarbon oils on metallic parts

- Aqueous spray, flush & immersed jets

- Compatible with a wide range of metals

-

TOPKLEAN MC 1007D

- Heavy contaminants removal

- Mono-solvent, co-solvent or spray process

- Environmental friendly alternative to perchlorethylene & nPB

-

PROMOSOLV SILI

- Silicon oil removal & carrier for silicon deposit

- Vapor phase process

- Excellent cleaning performance & low HSE impact

-

-

3M NOVEC 73DE

- Removal of a wide range of contaminants

- Vapor phase process

- Very low HSE impact & very low surface tension

Alternative: PROMOSOLV NEO B1

-

3M NOVEC 72DE

- Removal of a wide range of contaminants

- Vapor phase process

- High cleaning power & very low GWP

Alternative: PROMOSOLV NEO B1

-

3M NOVEC 71DE

- Removal of a wide range of contaminants

- Vapor phase process

- Medium cleaning power

Alternative: PROMOSOLV NEO B1

-