PROMOCLEAN TP 125

- Removal of burnt residues, oxides, polishing pastes, heavy greases & oil

- Aqueous immersion process

- Compatible with ferrous alloys & copper

Promoclean TP 125

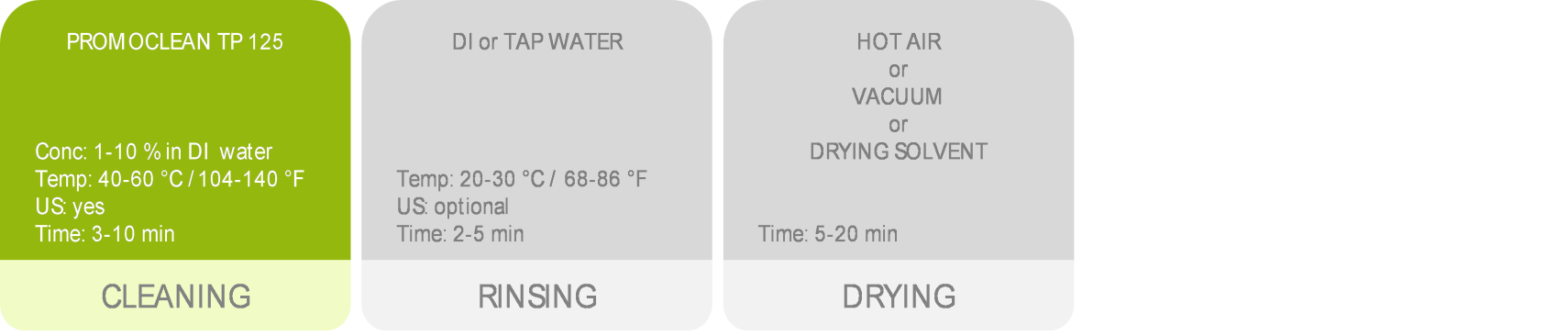

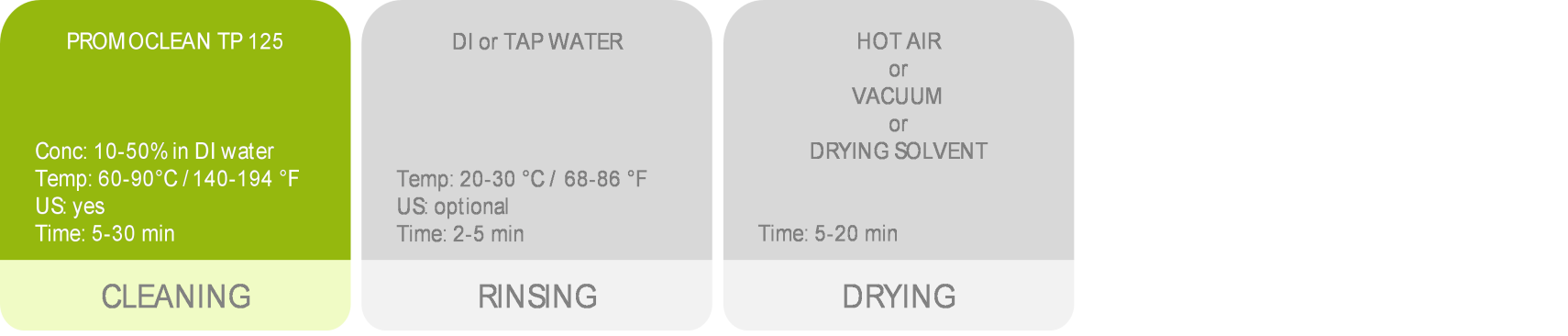

PROMOCLEAN TP 125 is especially designed for removal of strong pollutants in high quantities in an aqueous immersion process with ultrasonics. Its high pH allows efficient cleaning by saponification of heavy greases, oils, burnt residues, oxides and polishing pastes in metal parts production or for maintenance operations.

Itis a concentrated product which is used diluted with DI water or tap water without risk of lime deposits, thanks to its excellent chelating properties.

Promoclean TP 125 is dedicated for steel, iron, ferrous alloys & copper but cannot be used on sensitive metals like Aluminium or other light alloys.

This is not a product

Although fully in line with safety & environmental regulations, this product doesn`t match our strict criteria to be labelled as a Greenway product.

LOOKING FOR A MORE SUSTAINABLE SOLUTION?

GREENWAY ALTERNATIVE

- We currently don`t have a Greenway alternative but our target is to develop one in the near future. In case you want us to prioritize the development of a Greenway alternative, do not hesitate to contact us.

Benefits

Performance

- Cleans efficient all organic pollutants thanks to its high alkalinity

- Absorbs high quantity of pollutants

- Short rinsing time needed, despite being a high pH product

Cost

- High cleaning power even at low concentration

- Cleans efficient even at low temperature, reducing energy cost

- Long bath-life due to its capacity to absorb organic pollutants including burnt residues

HSE

- Non-toxic & no CMR substances

- Low chemical demand on oxygen for waste treatment

- Sustainable chelating agents without phosphorus ingredients

- Non-flammable