PROMOCLEAN TP 1113

Safest cleaner for Titanium

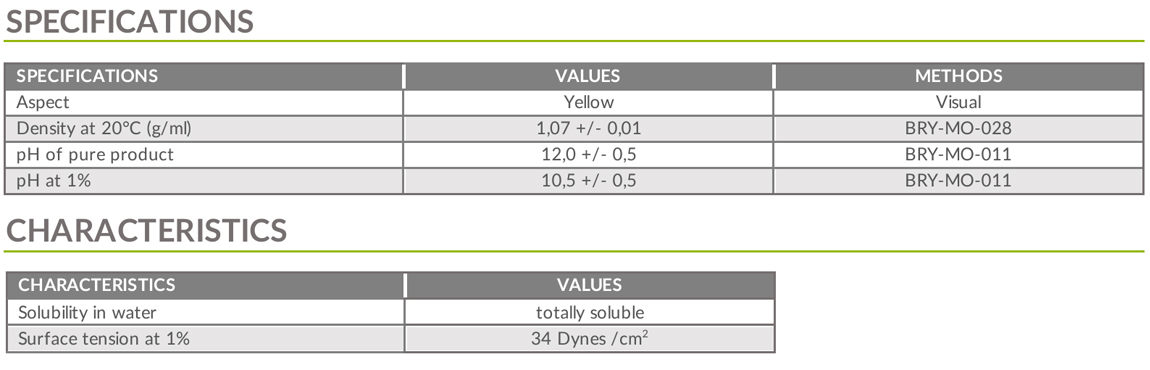

- Oil & Grease removal

- Aqueous immersion process

- Safe to use on Titanium & Aluminium

PROMOCLEAN TP 1113

Designed for removal of hydrocarbon- or water-based oils and greases in an aqueous immersion process. Despite having a high pH to allow efficient cleaning, it doesn’t damage sensitive metals or alloys, like Titanium, Aluminium, Copper or Brass. It’s a concentrated product which is used diluted with DI water.

Request a sample

for "PROMOCLEAN TP 1113"

This is a product

MAIN CONTRIBUTORS WHICH REDUCE IMPACT:

HUMAN HEALTH & SAFETY

- Non-flammable, no flashpoint & no EUH risk phrases: 100% safe for storage and when used in equipment

- Non-toxic

ENVIRONMENT PROTECTION & RESOURCES SAVINGS

- Low environmental impact: no H labelling regarding environment

- No GWP & Very low VOC (<25% of VOC compound)

- Made partially with renewable raw materials

Benefits

Performance

- Cleans efficient ALL metals, including very sensitive ones

- The low surface tension improves cleaning of parts with complex geometry

- Short rinsing time needed, despite being a high pH product.

Cost

- High cleaning power even at low concentration

- Can be te-used after infiltration

- Long bath-life

HSE

- Non toxic & no CMR substances

- Low environmental impact

- Non flammable

Process examples

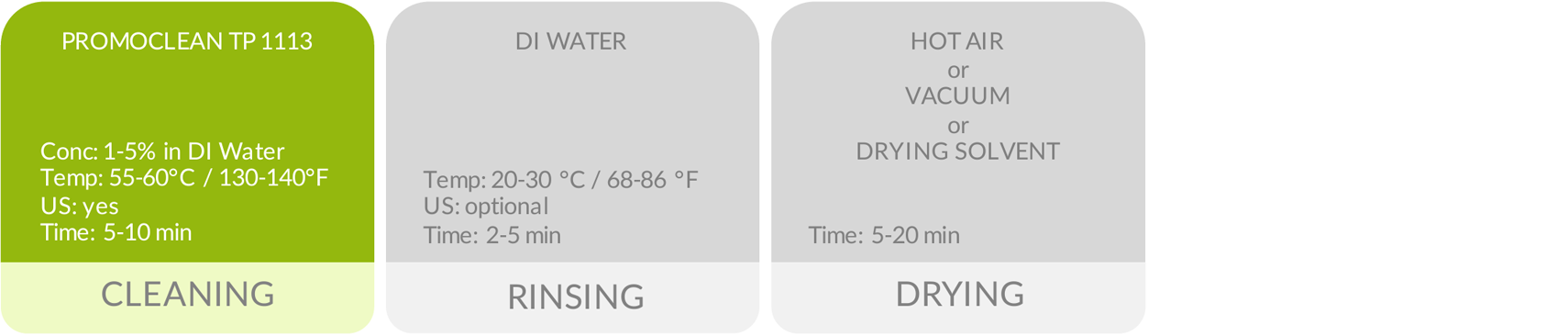

The most suitable process will depend on factors such as operating conditions, equipment, desired cleaning and the nature of the contaminants. Our team is therefore there to advise you.

Oil removal

- Increasing the bath-life of your process can be achieved by adding an oil separator within the cleaning equipment and to add periodically concentrated product.

- Compatibility report with different materials is available on request.

- Concentration can be monitored with a dedicated PCA KIT or with our PCA DIGITAL online analysing equipment.

- It is key to determine the maximum time materials can be exposed to the cleaning chemical. Although our cleaning products will not damage materials they are designed for under normal conditions, prolonged exposure may.

Applications

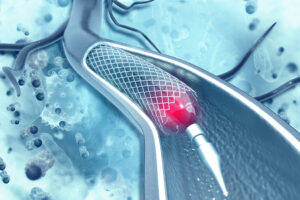

OIL REMOVAL FROM STENTS

Promoclean TP 1113 is used in the Medical industry to remove oil from stents in various alloys (Steel Inox 316L, Cobalt-Chrome, Titanium & nickel)

OIL REMOVAL FROM WATCH BRACELETS

Promoclean TP 1113 is used in the Jewelry & watch industry to remove oil & polishing paste from metal bracelets in a hybrid process.