TOPKLEAN MC 20D

- Oil & grease removal

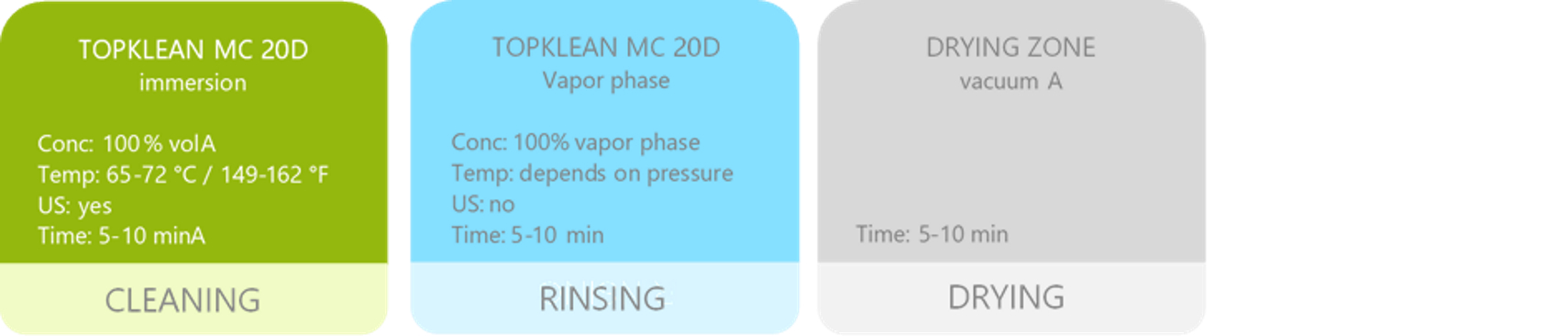

- Vacuum process

- Environmental friendly alternative to perchlorethylene & nPB

TOPKLEAN MC 20D

Especially designed to replace solvents with a high HSE impact such as nPB and perchloroethylene and to offer a product in accordance with the latest and future environmental regulations.

It is used in vacuum process to offer an environmentally friendly solvent solution without compromising on high cleaning performance. Its performance in solubilizing organic compounds allows it to remove hydrocarbon oils & greases from all metals and most plastics used in the industry. It could also remove a small quantity of water-soluble oils but need to be evaluated & tested before.

TOPKLEAN MC 20D is qualified and used by several actors in the aerospace industry (e.g. SAFRAN IN 1500B).

Benefits

Performance

- Excellent solubility of hydrocarbon oils & greases

- Excellent compatibility with all metals, glasses, ceramic & many plastics

- Allows excellent results in surface tension measurements of treated parts

Cost

- Continuous recycling in equipment for a long bath-life

- Limited consumption thanks to airtight equipment

- Thermally and chemically stable in use, so no need of using an additive

HSE

- Very low toxicity (refer to the SDS)

- No Ozon Depletion Potential (ODP) & low Global Warming Potential (GDP)

- High flash point (non-flammable for transport)

- No aromatics & halogenated compounds