PROMOSOLV DR1

- Solvent for rinsing & spotless fast drying

- Co-solvent & drying process

- Low GWP

- 3M Novec 71IPA replacement

Especially designed to replace rinsing solvents with a high HSE impact and to offer a product in accordance with the latest and future environmental regulations. It is used in combination with our TOPKLEAN™ range to offer an environmentally friendly solvent solution without compromising on high cleaning performance. The very low surface tension allows to penetrate very tight spaces, making sure any cleaning chemistry is fully removed after rinsing.

This product also exists in a recycled version (made from recycled solvent) under the name PROMOSOLV DR1 T.

PROMOSOLV DR1 is a drop-in replacement for 3M Novec 71IPA which is scheduled to be phased out voluntarily by end 2025. Click on the link for more info on the announcement of 3M Novec phase out.

Request a sample

for "PROMOSOLV DR1"

This is a product

MAIN CONTRIBUTORS WHICH REDUCE IMPACT:

HUMAN HEALTH & SAFETY

- Non-flammable & no flashpoint: 100% safe for storage and when used in equipment

- Non-toxic & no corrosive impact : no S risk labelling

ENVIRONMENT PROTECTION & RESOURCES SAVINGS

- Low environmental impact: no H labelling regarding environment

- Can be returned for recycling and re-use: ECOPROGRAM

- Reduce consumption of product, consumables, water & energy

Benefits

PERFORMANCE

- Thermal and chemical stable in use

- The very low surface tension allows deep rinsing of parts with complex geometry

- Short rinsing and drying times

COST

- Continuous recycling in equipment for a long bath-life

- Can be returned for recycling and re-use

- The relative high boiling point reduces risk of solvent drag, so limiting consumption

HSE

- No Ozon Depletion Potential (ODP)

- Low Global Warming Potential (GWP): 320

- Non-flammable & no flashpoint

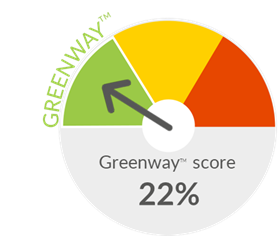

- Low environmental impact: GREENWAY product

Related products & services

PROMOSOLV DR1 T

- Light oil & particles removal / rinsing & drying

- Vapor phase, co-solvent, flushing & drying process

- Equivalent of DR1 but made from recycled solvent