PROMOCLEAN DEWAX+

- Removing wax, light oxides & mineral residues

- Aqueous immersion process with ultrasonics

- Perfect phase separation & sustainable

PROMOCLEAN Dewax+

Especially designed for removal of wax after surface treatment, light oxides and mineral residues (such a lime or finger traces). It’s a more sustainable alternative to chloride solvents. Due to ability to remove oxides it is also perfect to clean before coating or surface treatment like PVD but the right dilution and process parameters need to be confirmed.

This is a product

MAIN CONTRIBUTORS WHICH REDUCE IMPACT:

HUMAN HEALTH & SAFETY

- Non-flammable, no flashpoint & no EUH risk phrases: 100% safe for storage and when used in equipment

- Non-toxic & low corrosive impact

ENVIRONMENT PROTECTION & RESOURCES SAVINGS

- Low environmental impact: no H labelling regarding environment

- No GWP

- Very low VOC (<25% of VOC compound)

- Contains partial vegetable raw materials

Benefits

PERFORMANCE

- Excellent wax disposal in the bath by phase separation

- Fast action due to synergy between acid & surfactants

- Good deoxidation power which gives a bright effect on surface

- No residues after rinsing: can be used before surface treatment

COST

- High chelating power, reducing lime deposits: can be diluted in tap water

- High cleaning power even at low concentration

HSE

- Non-toxic & no CMR substances

- No hazardous acid such as hydrochloric nitric or sulfuric acids.

- Non-flammable

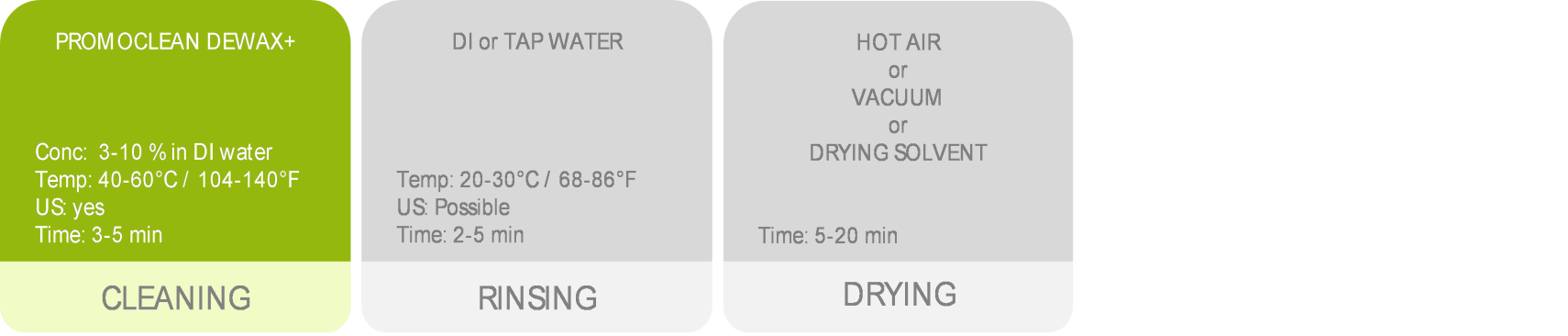

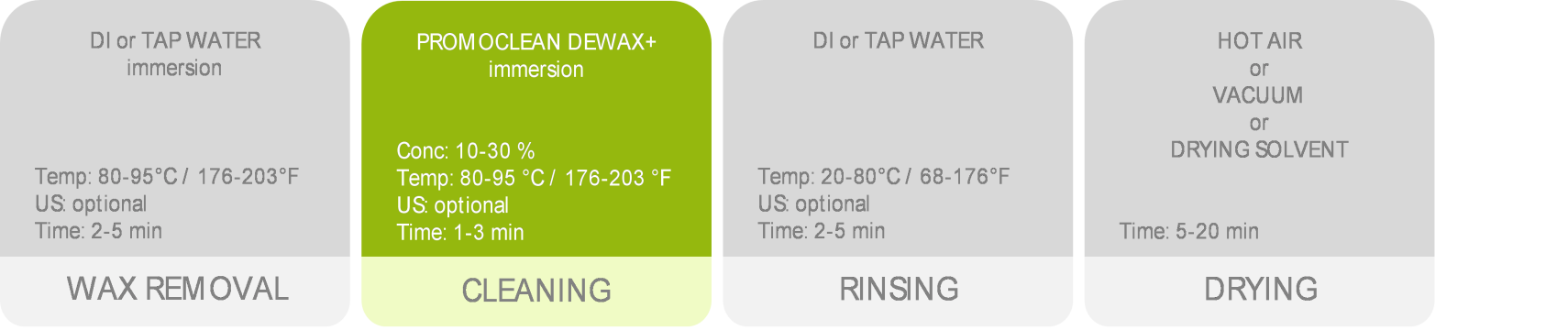

Process examples

The best process will depend on factors such as operating conditions, equipment, desired cleaning time and the nature of contaminants. Our team is ready to advise you.

Dewaxing metallic parts after surface treatment

- For dewaxing an equipment with separation system is needed in the cleaning tanks

- Dry ferrous metals immediately after rinsing to avoid corrosion.

- A dedicated PCA Kit to monitor the bath status and compatibility report with different materials are available on request.

- It`s key to determine the maximum time materials can be exposed to the cleaning chemical. Although our cleaning products will not damage materials they are designed for under normal conditions, prolonged exposure may.