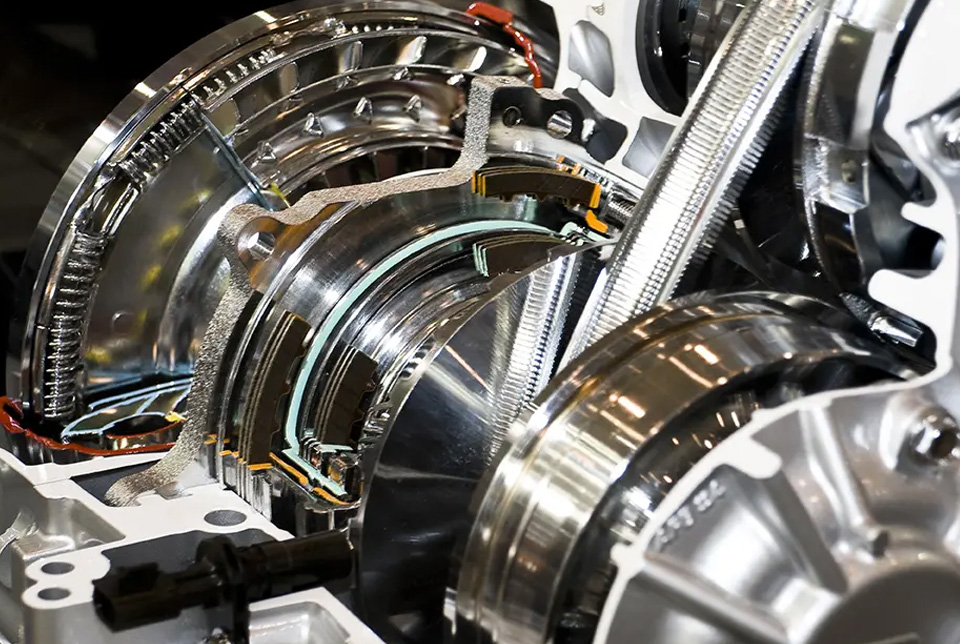

Oil removal from various metal components

Our advanced oil removal solutions are formulated to efficiently eliminate oils from diverse metal components, ensuring pristine surfaces, process reliability, and compatibility with high-precision manufacturing and finishing operations.

Advanced Oil Removal & Metal Cleaning Solutions

Effective oil removal is essential for maintaining the surface integrity and reliability of metal components. INVENTEC delivers tailored metal cleaning solutions for whole oils, soluble oils, and oil additives—ensuring optimal compatibility with materials and processes.

Choosing the right oil removal process depends on contamination type, metal alloy sensitivity, and production needs. INVENTEC offers safe and efficient degreasing solutions—whether aqueous or solvent-based—designed for delicate alloys, elastomers, and plastics.

Many of our metal cleaning products feature integrated corrosion protection, helping reduce process steps and cycle time. Our goal: effective cleaning with maximum process reliability.

Why Choose INVENTEC?

- Customized oil removal for all types of metal parts

- Bath life extension and odour control

- Handles complex or mixed oils with ease

- Optional temporary corrosion protection

Our Top Oil Removal Products

OIL REMOVAL SOLUTIONS

| Type of Pollutant | Type of Process | Product Solution |

|---|---|---|

| Hydrocarbon Oil | Co-Solvent |

|

| Mono-Solvent (Vapor Phase) |

|

|

| Vacuum |

|

|

| Aqueous Spray |

|

|

| Aqueous Immersion |

|

|

| Manual Cleaning |

|

|

| Water Soluble Oil | Co-Solvent | Not Recommended Process |

| Mono-Solvent (Vapor Phase) | Not Recommended Process | |

| Vacuum | Not Recommended Process | |

| Aqueous Spray |

|

|

|

WITH AEROSPACE HOMOLOGATION: |

||

| Aqueous Immersion |

|

|

| Manual Cleaning |

|

|

| Silicon Oil | Co-Solvent |

|

OIL REMOVAL + TEMPORARY CORROSION PROTECTION

| Type of Pollutant | Type of Process | Product Solution |

|---|---|---|

| Hydrocarbon Oil | Co-Solvent | No Corrosion Risk Due to Absence of Water in Cleaning Process |

| Mono-Solvent (Vapor Phase) | No Corrosion Risk Due to Absence of Water in Cleaning Process |

|

| Vacuum | No Corrosion Risk Due to Absence of Water in Cleaning Process |

|

| Aqueous Spray |

|

|

| Aqueous Immersion |

|

|

| Manual Cleaning |

|

|

| Water Soluble Oil | Co-Solvent | Not Recommended Process |

| Mono-Solvent (Vapor Phase) | Not Recommended Process | |

| Vacuum | Not Recommended Process | |

| Aqueous Spray |

|

|

| Aqueous Immersion |

|

|

| Manual Cleaning |

|

These tables show a selection of our metal cleaning and oil removal products. We also offer legacy and custom formulations. Contact us or use our product search tool for tailored guidance.

Benefits of Our Oil Removal Processes

- Co-solvent Cleaning: Topklean + Hydrofluoroether rinsing

- Mono-solvent Vapor Phase: Efficient one-step solvent cleaning

- Aqueous Spray: High-pressure cleaning in spray or inline systems

- Aqueous Immersion: Ultrasonic or agitated tank cleaning

- Manual Cleaning: Hand-applied for small parts or spot cleaning

INVENTEC delivers safe, high-performance solutions for all your metal cleaning needs. Our technologies are tailored to tackle the toughest oil removal and corrosion protection challenges.

See Other Degreasing Processes Read FAQ

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Showing all 15 results

-

-

PROMOSOLV NEO A1

- Light oil & particles removal / rinsing & drying

- Vapor phase, co-solvent, flushing & drying process

- No GWP & PFAS free

- 3M Novec 7100 replacement

-

PROMOCLEAN DISPER 10

- Oil removal with temporary protection

- Aqueous spray & flushing process

- Compatible with a wide range of metals

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

PROMOCLEAN TP 1114

- Oil & polishing paste removal with 1-3 days corrosion protection

- Aqueous immersion process

- Compatible with sensitive alloys

-

PROMOCLEAN TP 1117

- Oil & polishing paste removal with 3-7 days corrosion protection

- Aqueous immersion process

- Compatible with sensitive alloys

-

-

TOPKLEAN MC 20D

- Oil & grease removal

- Vacuum process

- Environmental friendly alternative to perchlorethylene & nPB

-

PROMOCLEAN DISPER 6

- Removing hydrocarbon & water-soluble oils on metal parts

- Detergent for spray, flush & immersed jets process

- Compatible with a wide range of metals

-

-

-

PROMOSOLV NEO B1

- Removal of a wide range of contaminants

- Vapor phase process

- PFAS free & no GWP

- 3M Novec 71DE, Novec 72DE, Novec 73DE, and Novec 8200 replacement

-

-

PROMOCLEAN DISPER 22

- Removal of grease, heavy oils, burn-in residues & oxides

- Aqueous spray processes

- Compatible with ferrous alloys

-

PROMOCLEAN TP 125

- Removal of burnt residues, oxides, polishing pastes, heavy greases & oil

- Aqueous immersion process

- Compatible with ferrous alloys & copper

-

QUICKSOLV FIDES

- Oil & dust removal for dielectric cleaning

- For manual spray equipment

- Safe & fast cleaning under power

-

-

-

-

-

TOPKLEAN MC 1007D

- Heavy contaminants removal

- Mono-solvent, co-solvent or spray process

- Environmental friendly alternative to perchlorethylene & nPB

-

PROMOCLEAN DISPER 13

- Detergent with temporary protection for removing light oils on metallic parts

- Aqueous spray, flush & immersed jets processes

- General cleaner for light contaminations

-

PROMOCLEAN DISPER 15

- Oil removal with temporary protection

- Polyvalent process: aqueous spray, immersion & flushing

- Compatible with wide range of metals

-

PROMOSOLV 70

- Removal of a wide range of contaminants

- Vapor phase process

- Very low GWP: 96

- 3M Novec 71DE, Novec 72DE, Novec 73DE replacement

-

BLUE GOLD

- Degreasing & particle removal from equipment in contact with oxygen

- Aqueous spray & immersion process

- Passes ASTM F-495 and ARP 1775A norm

-

PROMOCLEAN DISPER 11

- Detergent with temporary protection for removing light oils on metallic parts

- Aqueous spray, flush & immersed jets processes

- Compatible with a wide range of metals

-

PROMOCLEAN DISPER 3

- Detergent for removing hydrocarbon oils on metallic parts

- Aqueous spray, flush & immersed jets

- Compatible with a wide range of metals

-

PROMOSOLV SILI

- Silicon oil removal & carrier for silicon deposit

- Vapor phase process

- Excellent cleaning performance & low HSE impact

-

-

PROMOCLEAN TP 1115

- Removing polishing pastes & oils on metal parts

- Aqueous immersion process with ultrasonics

- Finishing & rinsing step with hard water possible

-

-

3M NOVEC 73DE

- Removal of a wide range of contaminants

- Vapor phase process

- Very low HSE impact & very low surface tension

Alternative: PROMOSOLV NEO B1

-

3M NOVEC 72DE

- Removal of a wide range of contaminants

- Vapor phase process

- High cleaning power & very low GWP

Alternative: PROMOSOLV NEO B1

-

3M NOVEC 71DE

- Removal of a wide range of contaminants

- Vapor phase process

- Medium cleaning power

Alternative: PROMOSOLV NEO B1

Discover our Efficient Oil & Grease Removal for Sensitive Alloys!

PROMOCLEAN TP 1113

- Oil & Grease removal

- Aqueous immersion process

- Safe to use on Titanium & Aluminium

This is a product

Oil Removal

Industrial Cleaning Solutions

Frequently Asked Questions (FAQ)

What is oil removal in industrial cleaning?

Oil removal is the process of eliminating oils, greases, and lubricants from metal and electronic components to ensure surface cleanliness for further processing like soldering, coating, or assembly.

Why is oil removal important before soldering or coating?

Residual oils can interfere with adhesion, cause defects like poor wetting, voids, or corrosion, and reduce the reliability of solder joints or coatings. Effective oil removal is critical for high-quality manufacturing.

What methods are commonly used for oil removal?

Methods include solvent-based degreasing, aqueous alkaline cleaning, ultrasonic cleaning, and vapor degreasing, chosen based on component type and contamination severity.

Which solvents are effective for oil removal?

INVENTEC offers a range of powerful degreasing solvents designed to dissolve and remove oils without damaging sensitive metals or electronics.

Are aqueous cleaners suitable for oil removal?

Yes, aqueous alkaline cleaners are effective and environmentally friendly options for removing oils, especially when combined with mechanical action such as ultrasonics.

How do I know if oil removal was successful?

Cleanliness can be verified through surface analysis techniques such as wipe tests, contact angle measurements, or residue analysis to ensure no oil traces remain.

Can oil removal processes be automated?

Yes, many industrial cleaning lines integrate automated degreasing and oil removal systems to improve consistency and throughput while reducing labor.

What environmental considerations are there for oil removal?

Modern oil removal solutions from INVENTEC emphasize low VOC emissions, biodegradability, and compliance with environmental regulations to minimize impact.

Does oil removal affect subsequent cleaning or assembly steps?

Proper oil removal enhances adhesion, improves solderability, and ensures coatings bond correctly, preventing defects downstream in the manufacturing process.

Does INVENTEC provide solutions for industrial oil removal?

Yes, INVENTEC Performance Chemicals offers a comprehensive range of oil removal and degreasing products tailored to meet the stringent needs of industrial electronics and metal component cleaning.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.