Polishing Compounds Removal

Solutions for difficult to remove substances like polishing paste, diamond polishing liquid, polymers & resins without harming the substrates they have to removed from. Suited for your desired process and formulated to meet today’s environmental regulations and beyond.

Select subsegment :

Liquid Diamond Polish Removal

The cleaning of Liquid Diamond Polishing is essential in industries to maintain optimal tool performance, prevent material buildup, and ensure the accuracy and finish of precision surfaces.

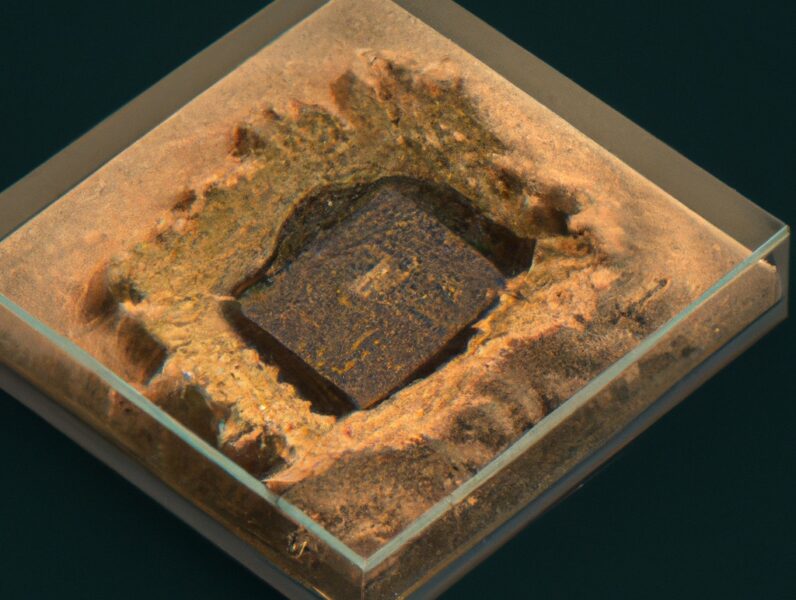

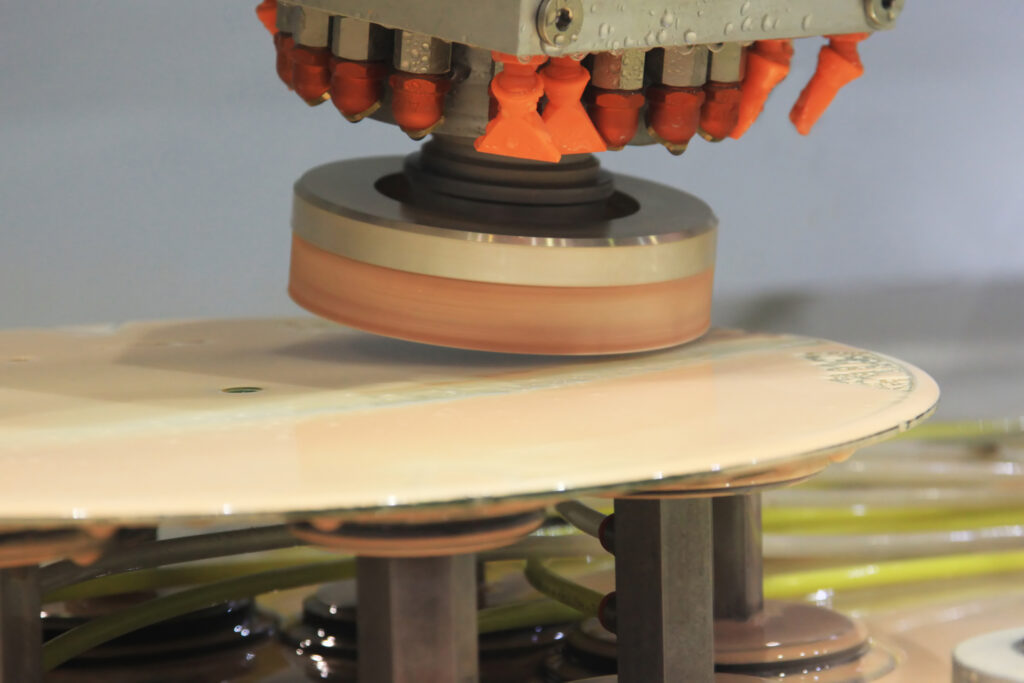

The machining and polishing of parts that are particularly hard and difficult to work with, such as tungsten carbide cutting tools, require the use of fluids that are especially adapted to these operations.

Liquid diamond polish is widely used in this case but is also particularly sticky and consist of very small particles. The polish liquid deposits in cavities and pores of the parts, which makes the cleaning of these parts challenging. This demands for a precise and repeatable cleaning process for a high-speed production environment.

INVENTEC offers a range of products whose characteristics allow:

- excellent cleaning result taking into account the porosity of the parts,

- a solution which accommodate high production volumes (long bathlife),

- respecting environmental regulations and criteria.

Polishing Paste Removal

The cleaning of Polishing Paste in industries is important to ensure the removal of contaminants, enhance product quality, and maintain the efficiency and longevity of equipment used in polishing and finishing operations.

The requirements to remove polishing paste are different from one client to another. The multiple metals, very small & complex parts, composition of the polishing paste (mineral or organic), production throughput, water waste and many other concerns users today.

The principal constraints are the attacks of the alloys that make up the parts to be cleaned. How to avoid micropile corrosion in alloys such as brass, monel or mesh, while ensuring optimum cleaning quality?

INVENTEC has the expertise to answer all these problems thanks to its wide range of products: from aqueous solutions, to solvents to hybrid solutions, INVENTEC will adapt your process by optimizing cleaning quality and process costs.

Read morePolymer & Resin Removal

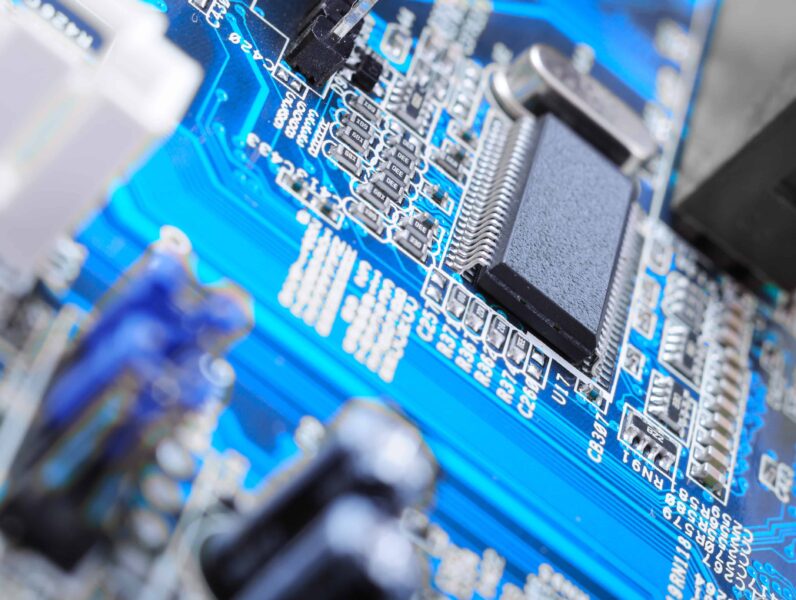

Cleaning polymer and resin residues in the semiconductor and electronics industries is essential to maintain the integrity, performance, and reliability of components, preventing defects and ensuring optimal functionality in sensitive applications.

In order to guarantee the reliability of a subsequent process, any polymerized residues must be removed.

The right choice of a cleaning product is fundamental as it must allow a fast and effective destruction of the polymerized bonds, the removal of the residues, while preserving the integrity of the treated part. You may find effective products on the market but many times they may raise concerns regarding safety (e.g. flammable), health (toxic substances) or environment when you discharge them or by emissions.

INVENTEC offers a range of products whose characteristics and implementation consider:

- the nature of the polymer residues to be removed,

- the cleaning agent compatibility with the part to be cleaned,

- the sustainable impact of the process.

We can assist you in choosing the best solution in terms of performance and economic within a framework that respects environmental criteria.

Read moreWax Removal

The cleaning of wax in electronics and precision manufacturing is important to prevent contamination that can impact the performance, reliability, and lifespan of delicate components.

Wax removal is an essential step in many industrial cleaning applications, particularly in electronics and precision manufacturing, where residual wax can interfere with the functionality and quality of the end product. INVENTEC offers a variety of specialized products designed to effectively remove wax, ensuring a clean surface and optimal performance of components.

For efficient wax removal, one of the most effective methods is the co-solvent process using TOPKLEAN MC 1007. This product is formulated to efficiently dissolve and remove wax residues, while also ensuring compatibility with sensitive surfaces, making it ideal for use in complex cleaning environments.

Alternatively, the mono-solvent (vapor-phase) process provides another effective approach to wax removal, utilizing PROMOSOLV 70 and 3M Novec 73DE. These products offer high solvency power in vapor-phase cleaning systems, effectively lifting wax and other contaminants from intricate components without causing damage. This method is highly effective for cleaning delicate electronics or parts with fine details.

For aqueous immersion cleaning, PROMOCLEAN DEWAX+ is the product of choice. This aqueous solution is specifically designed for wax removal delivering excellent performance in water-based cleaning systems. It is highly effective in immersing and breaking down wax residues, ensuring a thorough clean with minimal environmental impact.

Whether you are looking for a co-solvent, vapor-phase, aqueous immersion, or manual cleaning solution, INVENTEC’s range of products ensures efficient wax removal with excellent cleaning power, providing a reliable and versatile solution for your cleaning needs.

The tables below give an overview and which product we recommend according to your desired wax removal process.

| Type of Pollutant | Type of Process | Product Solution |

|---|---|---|

| Waxes | Co-Solvent |

|

| Mono-Solvent (Vapor Phase) |

|

|

| Vacuum | Not Recommended Process | |

| Aqueous Spray | Not Recommended Process | |

| Aqueous Immersion |

|

|

| Manual Cleaning |

|

Above table is a non exhaustive list. INVENTEC offers more products which could be older and for which we have an improved formulation or a fine-tuning to a specific need. You may find a specific product via our search option or contact us for more information.

What are the different processes?

- Co-solvent: solvent process with Topklean products as cleaning agent and Hydrofluoroethers as rinsing solvent

- Mono-solvent: vapor phase cleaning with 1 single solvent for cleaning & rinsing

- Aqueous spray: spray in air / spray in line / immersion jets / water based flushing

- Aqueous Immersion : immersion in tank with options for heating, ultrasonics, agitation (moving of cleaning baskets)

- Manual cleaning: spray, poor or dip in simple tank without heating

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.

Looking for another

cleaning solution ?

Search our entire cleaning range

You don’t find the

right product ?

Let’s discuss about your challenge

Polishing Compounds Removal Guide

High-quality compound remover products are designed to break down stubborn polishing paste and diamond polishing paste on metal, plastic, or composite surfaces. Efficient polishing compounds removal is critical in environments requiring flawless finishes and absolute cleanliness. These removers are used in both manual cleaning and automated systems, delivering consistent results across high-throughput production lines. In addition to enabling smooth downstream processes, thorough wax removal and resin removal help extend equipment life by preventing buildup. As industrial standards tighten, manufacturers in sectors like automotive, aerospace & defense, and medical increasingly rely on advanced compound remover solutions to meet both functional and regulatory expectations.

Automotive – Performance Starts with Clean Surfaces

In the automotive industry, effective polishing compounds removal ensures that painted and metallic parts are free of contaminants. The use of a reliable compound remover is crucial for removing polishing paste and diamond polishing paste from engine components, body panels, and trim. Thorough wax removal and resin removal allow for optimal adhesion in coatings, improving durability and aesthetics.

Discover our Automotive Solutions by Segment

Aerospace & Defense – Clean Components for Critical Missions

In aerospace & defense, the demand for surface precision is non-negotiable. Effective polishing compounds removal eliminates every trace of polishing paste and diamond polishing paste used in part finishing. Specialized compound remover solutions ensure complete wax removal and resin removal from sensitive components like turbine blades and radar parts, ensuring compliance with strict industry standards.

Discover our Aerospace & Defense Solutions by Segment

Medical – Safe, Sterile, Spotless

In the medical field, cleanliness is a critical safety factor. The thorough polishing compounds removal of surgical instruments, implants, and devices is achieved using high-grade compound remover solutions. These cleaners are specifically formulated for removing diamond polishing paste, polishing paste, and stubborn resin residues. Complete wax removal ensures biocompatibility and prevents contamination in sterile environments.

Discover our Medical Solutions by Segment

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Read moreShowing all 2 results

-

PROMOCLEAN TP 178

- Removing oxides, mineral residues & diamond liquid polishing

- Aqueous immersion process with ultrasonics

- Substitute for phosphoric acid based cleaners

-

TOPKLEAN MC 1007D

- Heavy contaminants removal

- Mono-solvent, co-solvent or spray process

- Environmental friendly alternative to perchlorethylene & nPB