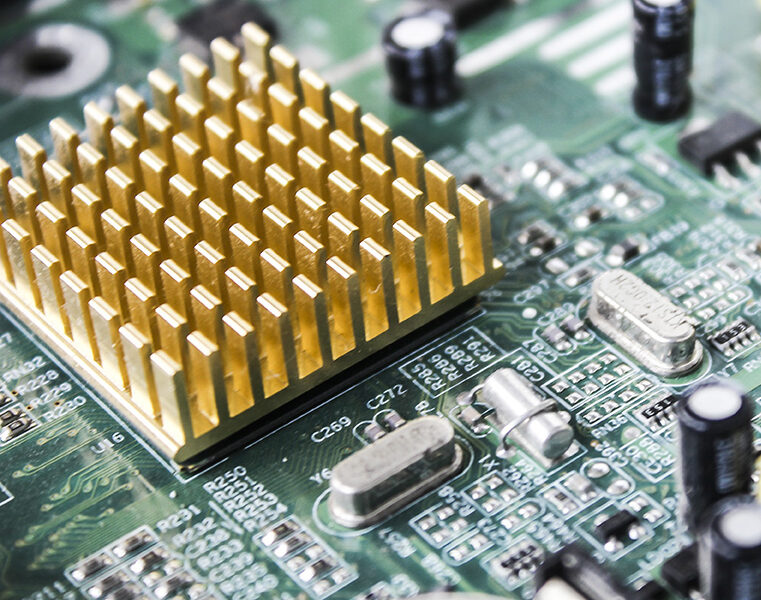

Soldering Fluxes

Best in class liquid solvent- or the more environmental friendly water based fluxes for wave, selective soldering and tinning. Our range of tacky fluxes, including resin based, no-clean, low-residue.

Soldering Flux Solutions

for Every Assembly Challenge

Soldering flux is a critical element in electronic assembly, enabling proper wetting, removing oxides, and ensuring reliable solder joints. Its composition and performance directly influence process stability, joint integrity, and the long-term reliability of electronic devices.

Select subsegment :

Wave Soldering flux

Wave soldering flux is essential for cleaning metal surfaces, preventing oxidation, reducing surface tension, and ensuring proper solder flow, and INVENTEC provides high-performance solutions that enable strong, reliable solder joints while minimizing defects during the wave soldering process.

Discover high-performance wave soldering flux solutions engineered to meet the reliability, efficiency, and sustainability demands of modern through-hole soldering processes…

Learn more

Selective Soldering flux

Selective soldering flux plays a crucial role in the electronics manufacturing process by facilitating optimal solder flow, preventing oxidation, and minimizing defects—benefits that INVENTEC delivers through its advanced solutions to enhance the reliability and durability of electronic components and assemblies.

ECOFREC™ introduces advanced selective soldering flux solutions that enhance the performance of selective solder and selective wave soldering processes, ensuring optimal solder flow, superior wetting, and high-reliability solder joints for electronics manufacturing…

Learn more

Tacky Flux

Tacky flux plays a critical role in the soldering process by cleaning and preparing metal surfaces, while INVENTEC enhances this process with advanced formulations that remove oxides, improve solder adhesion, prevent contamination, and ensure reliable electrical connections for optimal performance in electronic assemblies.

Discover the power of high-performance tacky flux solutions designed to meet the demanding needs of BGA reballing, BGA repair, BGA assembly, and QFP rework with unmatched precision, reliability, and ease…

Learn more

Tinning Flux

Tinning flux is essential in soldering as it cleans and prepares metal surfaces by removing oxidation to ensure strong solder adhesion and prevent weak joints—functions that INVENTEC delivers through its high-performance flux solutions, enhancing the reliability and longevity of electronic connections.

For consistent, high-quality cable assembly across various applications, using the right tinning flux is essential to ensure optimal soldering performance, long-term reliability, and regulatory compliance in demanding production environments…

Learn more

Discover our newest water-based no-clean liquid flux!

ECOFREC 320

- Water-based no-clean liquid flux

- Wave & selective soldering

- High reliability & excellent wetting

This is a product

Soldering Fluxes

Industrial Soldering Solutions

Frequently Asked Questions (FAQ)

Why are soldering fluxes important in electronic assembly?

Soldering fluxes are essential in electronic assembly because they ensure optimal wetting, oxide removal, and reliable solder joint formation. Choosing high-quality soldering fluxes improves electrical reliability and mechanical strength in PCBs and components.

What types of soldering fluxes does INVENTEC offer?

INVENTEC provides a full range of soldering fluxes, including solvent-based liquid fluxes and environmentally friendly water-based fluxes. These soldering fluxes are designed for wave soldering, selective soldering, and tinning processes, ensuring consistent quality and minimal defects.

What is the difference between no-clean and low-residue soldering fluxes?

No-clean soldering fluxes leave minimal harmless residues and require no post-cleaning, while low-residue soldering fluxes minimize residue without compromising wetting performance or joint reliability. Both types of soldering fluxes maintain high-quality solder joints.

How do tacky soldering fluxes improve selective soldering?

Tacky soldering fluxes, including resin-based formulations, provide precise placement, reduced bridging, and enhanced wetting for selective soldering. These soldering fluxes ensure high reliability and consistent soldering results.

Can INVENTEC soldering fluxes be used for wave soldering?

Yes. INVENTEC soldering fluxes are formulated for wave soldering, selective soldering, and tinning. These soldering fluxes guarantee consistent wetting, defect-free joints, and long-term reliability.

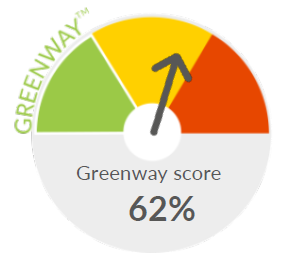

How do water-based soldering fluxes support sustainability?

Water-based soldering fluxes reduce solvent emissions and environmental impact while maintaining excellent wetting and reliable solder joints. Using eco-friendly soldering fluxes aligns with modern environmental regulations.

What factors influence the performance of soldering fluxes?

The composition, viscosity, solids content, and process parameters of soldering fluxes directly affect wetting, solderability, and post-solder cleanliness. Selecting the right soldering fluxes ensures consistent and high-quality joints.

How should soldering fluxes be stored?

Store soldering fluxes in a cool, dry place away from direct sunlight and tightly sealed. Proper storage preserves activity, viscosity, and shelf life of soldering fluxes, ensuring reliable soldering performance.

How does selecting the right soldering fluxes impact assembly reliability?

Choosing the correct soldering fluxes ensures consistent wetting, minimal residues, and defect-free solder joints, directly improving electrical, mechanical, and long-term reliability of assemblies.

How can INVENTEC support soldering fluxes optimization?

INVENTEC provides technical consultancy, tailored flux formulations, and application support to optimize soldering fluxes performance, reduce defects, and improve production yield.

Soldering Fluxes: Essential Guide for High-Performance Electronic Assembly

Soldering fluxes are indispensable in modern electronics manufacturing, ensuring proper wettability, removal of oxides, and long-term joint reliability. They are used in SMT assembly, wave soldering, and rework operations.

The choice of flux chemistry — such as rosin-based fluxes, no-clean fluxes, water-soluble fluxes, or low-residue fluxes — directly impacts solder joint quality, ionic cleanliness, and compatibility with conformal coatings. Proper flux activity guarantees stable wettability on different metal finishes including copper, nickel, and tin-silver alloys.

Innovations in low-VOC flux formulations and halogen-free fluxes meet growing requirements for environmental compliance (RoHS, REACH) and high-reliability electronics.

Benefits & Applications

Key BenefitsSoldering fluxes enhance the wettability of metal surfaces and ensure consistent solder joint formation. Optimized industrial soldering fluxes minimize oxidation, reduce defects such as voids or bridges, and improve the reliability of electronics assemblies and printed circuit boards (PCBs).

Technical AspectsSoldering fluxes are available in rosin-based, water-soluble, and No-Clean formulations, each tailored for specific reflow and wave soldering processes. High-performance soldering fluxes offer controlled activation, excellent thermal stability, and compatibility with diverse metal alloys used in industrial electronics.

ApplicationsSoldering fluxes are widely used in automotive electronics, aerospace & defense PCB assemblies, and medical devices. They ensure strong electrical connections, reduce component failure, and improve production yield in complex surface-mount technology (SMT) and through-hole assemblies, while adhering to strict environmental and safety standards.

Soldering Fluxes in Automotive Electronics

In the automotive industry, soldering fluxes are critical for assembling ECUs, powertrain control units, electric vehicle inverters, and battery management systems. They provide thermal cycling resistance and ensure long-term durability under harsh environmental conditions.

Soldering Fluxes in Aerospace & Defense

For aerospace and defense electronics, soldering fluxes are used in avionics, satellite communication systems, and radar assemblies. High-reliability no-clean fluxes minimize ionic residues, ensuring mission-critical performance in extreme environments.

Soldering Fluxes in Medical Electronics

In the medical industry, soldering fluxes are essential for patient monitoring systems, implantable medical devices, and diagnostic imaging equipment. Halogen-free fluxes and low-residue formulations are often required to ensure biocompatibility and long-term reliability.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

Do you need cleaning or coating after soldering? We provides FREE-OF-CHARGE cleaning or coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.