Rinsing & Drying solvents

Environmental friendly solvents for rinsing in a Co-solvent process for cleaning of electronic and mechanical parts. Dedicated range for water removal processes as a faster and more environmental alternative for drying by hot air.

Select subsegment :

Rinsing solvents

Rinsing solvents play a critical role in industrial cleaning within the automotive and aerospace sectors by ensuring the complete removal of contaminants and cleaning residues, which is essential for surface integrity, coating adhesion, and overall component performance.

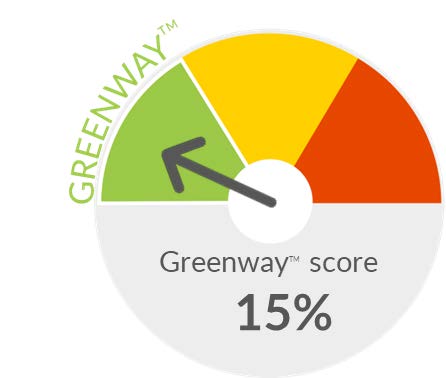

Rinsing solvents are used in our co-solvent processes. While the cleaning action is done with a product from our Topklean™ range, the rinsing is done with specially selected solvents for best process performance & compatibility. Our Promosolv™ range offers the most sustainable & risk free solvents available today.

- Non flammable

- No Ozone depletion (ODP)

- Low global Warming Potential (GWP)

They also can be used as cleaner for particles removal or to eliminate very light contaminations in vapor phase or flushing process.

CO-SOLVENT PROCESS

Inventec pioneered the co-solvent process two decades ago as an innovative solution to replace the utilization of HCFCs, trichloroethylene (Trike), perchloroethylene (PERC), n-propyl bromide (nPB), and other unsustainable solvents for cleaning purposes. This groundbreaking approach provided a safer alternative by effectively matching the cleaning performance of these solvents while significantly reducing associated health and environmental risks.

RECYCLING MADE EASY

For more information on our recycling service and in which countries we currently can offer this service, please follow the link: ECOPROGRAM

Read moreDrying Solvents

In industrial cleaning solutions for sectors like automotive and aerospace, drying solvents are crucial for ensuring rapid evaporation without residue, enabling faster processing and preventing corrosion or contamination on precision components.

Even when you are choosing or working with a water based cleaning system, you have the option to choose for drying with solvents as an alternative to drying with hot air.

Inventec has worked out an innovative drying solution, which works by the principle of water displacement by more heavier solvents. The solvents used are the most sustainable solvents on the market today.

ADVANTAGES

There are several functional as environmental & cost advantages to de-water with solvents

- Faster drying (5 minutes vs 30 minutes)

- Less energy usage

- Guaranteed water removal under low-stand-off components in electronics

- Guaranteed water removal in difficult to reach complex geometrical shapes of mechanical parts.

- Spot-free drying for high quality parts

- No risk to damage heat sensitive parts

- No risk for corrosion by residual water

DOWNLOADS

Last but not least, all solvents we offer can be returned to us for recycling. For more information on our recycling service, called ECOPROGRAM, and in which countries we currently can offer this service, please follow the link: ECOPROGRAM.

Read moreTechnical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.