Additive Manufacturing Solutions

Dedicated offer for the 3D manufacturing industry for cleaning, surface treatment and maintenance processes.

Additive Manufacturing Cleaning & Surface Treatment Solutions

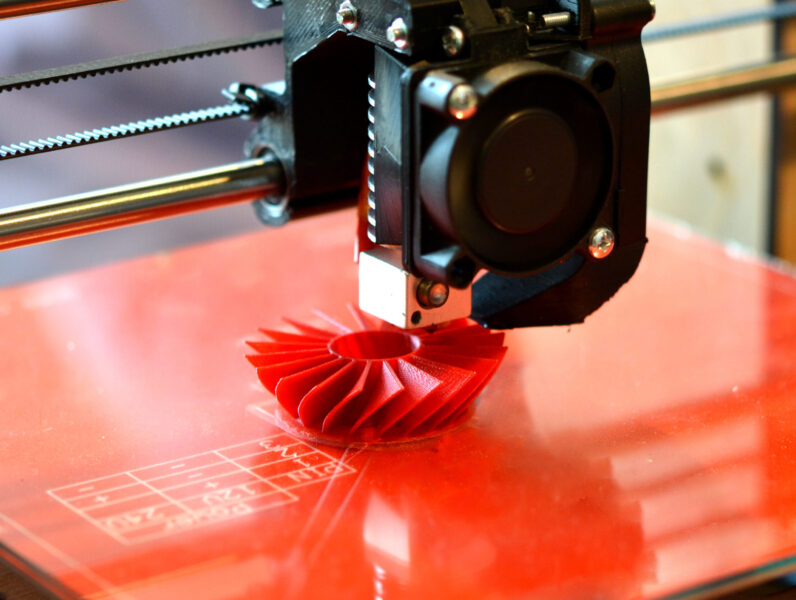

Cleaning and surface treatment in Additive Manufacturing (AM), also known as 3D printing, are essential to maintain equipment efficiency, guarantee high-quality printed parts, and reduce the risk of contamination. INVENTEC provides specialized solutions to support these critical processes, ensuring reliable and reproducible results for industrial applications.

Additive Manufacturing has transformed the industrial world by enabling the production of complex parts, improving material efficiency, and allowing the creation of lightweight components while maintaining high-performance requirements. These advantages bring with them specific needs in cleaning, surface treatment, and post-processing.

INVENTEC draws on decades of expertise in high-tech cleaning and surface treatment to adapt our solutions to the specific requirements of AM technologies and the wide variety of materials used.

Main Application Domains in Additive Manufacturing:

- Particle removal: elimination of loose metal or polymer particles from printed parts

- Polymer cleaning: dedicated cleaning solutions for polymer-based AM materials

- Post-treatment: surface finishing and preparation for coating or assembly

- Stripping: removal of support materials or unwanted coatings

- Maintenance: cleaning and upkeep of 3D printing equipment

Commitment to Innovation:

Additive manufacturing is a constantly evolving field, with new materials and processes emerging every day. INVENTEC works closely with major industry players to anticipate and respond to these developments, ensuring that our solutions remain at the cutting edge of technology and safety.

If you have specific requirements or technical questions, don’t hesitate to contact our experts.

Hydrofluoric acid and related formulations are supplied by our sister company Soderec. Click below to visit their website:

INVENTEC delivers dedicated additive manufacturing solutions for cleaning, post-processing, and maintenance. By combining safety, efficiency, and compliance with industry standards, we help manufacturers improve productivity, extend equipment life, and ensure consistent part quality.

See Other Cleaning Solutions Discover our guide Read FAQ

Read moreShowing all 11 results

-

-

PROMOCLEAN DISPER 10

- Oil removal with temporary protection

- Aqueous spray & flushing process

- Compatible with a wide range of metals

-

PROMOCLEAN TP 188

- Stripping of cured or polymerised substances

- Aqueous immersion, flushing & co-solvent process

- Environmental friendly substitution for NMP & chlorinated solvents

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

TOPKLEAN MC 20D

- Oil & grease removal

- Vacuum process

- Environmental friendly alternative to perchlorethylene & nPB

-

-

-

PROMOCLEAN TP 186B

- Removing varnish, resins, paints, glues, inks & lacquers

- Aqueous immersion & co-solvent process

- Very low environmental impact

-

-

TOPKLEAN MC 1007D

- Heavy contaminants removal

- Mono-solvent, co-solvent or spray process

- Environmental friendly alternative to perchlorethylene & nPB

-

PROMOSOLV 70

- Removal of a wide range of contaminants

- Vapor phase process

- Very low GWP: 96

- 3M Novec 71DE, Novec 72DE, Novec 73DE replacement

-

Material-Compatible Cleaning & Surface Treatment

Choosing the right cleaning or surface treatment solution requires a clear understanding of the materials and processes involved in AM to achieve optimal performance and quality.

| Metals | Ceramics | Hybrids |

|---|---|---|

|

|

|

|

INVENTEC Solutions for Additive Manufacturing

The following table provides an overview of recommended INVENTEC products and ranges for each additive manufacturing application domain:

| Application | Materials / Main Technology | Solutions |

|---|---|---|

| Particle elimination | All types / Selective Laser Melting |

|

| Post treatment | Metal / All types |

|

| Resins removal | Resins & Polymers / Stereolithography (SLA), filament, dual filament |

|

| Stripping | Metal / All types |

|

| Maintenance | Resins & Polymers / All types |

– Aerosol: QUICKSOLV DEF 70 – Simple immersion, circulation or brushing: QUICKSOLV DEF 90, TOPKLEAN MC 20C, PROMOCLEAN TP 188, PROMOCLEAN TP 186B |

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Read more

Showing all 11 results

-

-

PROMOCLEAN DISPER 10

- Oil removal with temporary protection

- Aqueous spray & flushing process

- Compatible with a wide range of metals

-

PROMOCLEAN TP 188

- Stripping of cured or polymerised substances

- Aqueous immersion, flushing & co-solvent process

- Environmental friendly substitution for NMP & chlorinated solvents

-

TOPKLEAN MC 20D

- Oil & grease removal

- Vacuum process

- Environmental friendly alternative to perchlorethylene & nPB

-

-

-

PROMOCLEAN TP 186B

- Removing varnish, resins, paints, glues, inks & lacquers

- Aqueous immersion & co-solvent process

- Very low environmental impact

-

-

TOPKLEAN MC 1007D

- Heavy contaminants removal

- Mono-solvent, co-solvent or spray process

- Environmental friendly alternative to perchlorethylene & nPB

-

PROMOSOLV 70

- Removal of a wide range of contaminants

- Vapor phase process

- Very low GWP: 96

- 3M Novec 71DE, Novec 72DE, Novec 73DE replacement

-

Discover Our Metal-Safe Cleaner for Additive Manufacturing!

PROMOCLEAN TP 1113

- Oil & Grease removal

- Aqueous immersion process

- Safe to use on Titanium & Aluminium

This is a product

Additive Manufacturing

Industrial Cleaning Solutions

Frequently Asked Questions (FAQ)

What is additive manufacturing cleaning?

Cleaning in additive manufacturing refers to the processes used to remove residual powders, support materials, and other contaminants from 3D printed parts to prepare them for final use or further post-processing. It also includes maintenance cleaning—regular operations during and between production cycles (cleaning exposed surfaces, dust extraction, chamber and tool maintenance, etc.)—to ensure process quality, repeatability, and safety.

Why is cleaning important in additive manufacturing?

Proper cleaning ensures the functionality of parts, surface quality, and dimensional accuracy. It removes polymer residues (binders, supports, unmelted filaments) present in powders or filaments that could otherwise affect mechanical properties or cause defects in subsequent treatments. Additionally, before sintering or any thermal treatment, thorough cleaning is essential to prevent contamination, reduce porosity, and ensure optimal furnace operation. It also contributes to safety and prepares parts for further processing such as coating or assembly.

What types of contaminants are typically removed?

Common contaminants include uncured resins, support structures, powder residues (metal, polymer, or ceramic), oils, and build chamber debris.

Which materials can benefit from cleaning solutions in additive manufacturing?

Materials such as metals, polymers, and ceramics used in various 3D printing technologies benefit from cleaning to optimize surface integrity and overall performance.

Are there specific cleaning processes for different 3D printing technologies?

Yes. Cleaning approaches vary for technologies such as SLS, SLA, DMLS, FDM, and MJF, each requiring tailored methods and chemistry to protect part quality.

How does surface treatment support additive manufacturing?

Surface treatment is an integral part of post-processing in additive manufacturing. It improves adhesion, aesthetics, surface roughness, and mechanical properties. It also removes oxidation or residual traces after sintering, which can impact functional performance or compromise the integrity of the parts—especially in critical applications.

Can the cleaning process be automated?

Yes. Automated cleaning systems increase consistency, reduce manual labor, and minimize contamination risks, especially in high-volume production environments.

What role does maintenance play in 3D printing productivity?

Regular maintenance of 3D printing equipment, including cleaning print heads, chambers, and filters, prevents defects, downtime, and premature wear.

Does INVENTEC offer solutions tailored to additive manufacturing?

Yes. INVENTEC has developed dedicated cleaning and surface treatment solutions optimized for the unique challenges of 3D-printed parts and materials.

Are these solutions compliant with industry standards?

INVENTEC’s cleaning and treatment processes are designed to support compliance with quality, safety, and environmental standards relevant to advanced manufacturing industries.

Additive Manufacturing Solutions: Cleaning, surface treatment, and maintenance for 3D manufacturing

Additive manufacturing (AM) or 3D printing requires specialized cleaning, surface preparation, and maintenance solutions to ensure component performance, durability, and precision. Residues from powders, binders, and support materials must be carefully removed without damaging delicate geometries.

Our dedicated industrial cleaning solutions for additive manufacturing include ultrasonic cleaning, precision solvent cleaning, surface activation, and maintenance chemicals compatible with metallic, polymeric, and composite materials. These processes improve surface finish, mechanical properties, and regulatory compliance for critical parts.

Industries such as automotive, aerospace & defense, and medical devices leverage these solutions for functional prototypes, custom implants, and high-precision mechanical components. Effective cleaning and maintenance directly enhance product reliability, performance, and lifecycle longevity.

Benefits & Applications

Key BenefitsAdditive Manufacturing solutions enable precise cleaning and surface preparation of 3D-printed components. These industrial cleaning processes ensure removal of residual powders, support materials, and contaminants, improving part reliability, quality, and overall manufacturing efficiency for additive manufacturing production lines.

Technical AspectsAdditive Manufacturing cleaning solutions are formulated for both metallic and polymeric 3D-printed components. The processes include powder removal, solvent cleaning, ultrasonic cleaning, and surface finishing. Optimized maintenance cleaning minimizes residue buildup and extends equipment lifespan, ensuring consistent print quality and part performance.

ApplicationsAdditive Manufacturing solutions are widely used in aerospace, medical devices, and high-precision industrial manufacturing. These solutions clean printed parts, tooling components, and prototypes to meet strict quality standards, improve component reliability, and support advanced 3D printing processes including metal, polymer, and hybrid additive manufacturing technologies.

Additive Manufacturing in Automotive Industry

3D printed automotive parts such as functional prototypes, custom brackets, or engine components require powder removal, support structure cleaning, and surface finishing to ensure durability and regulatory compliance.

Additive Manufacturing in Aerospace & Defense

3D printed aerospace components for satellites, engine parts, or structural components need precise particle removal, surface conditioning, and residue-free cleaning to ensure mechanical reliability and mission safety.

Additive Manufacturing in Medical Industry

Custom implants, prosthetics, and surgical tools produced by additive manufacturing require residue-free cleaning, surface treatment, and maintenance to guarantee patient safety and regulatory compliance.

Showing all 11 results

-

-

PROMOCLEAN DISPER 10

- Oil removal with temporary protection

- Aqueous spray & flushing process

- Compatible with a wide range of metals

-

PROMOCLEAN TP 188

- Stripping of cured or polymerised substances

- Aqueous immersion, flushing & co-solvent process

- Environmental friendly substitution for NMP & chlorinated solvents

-

TOPKLEAN MC 20D

- Oil & grease removal

- Vacuum process

- Environmental friendly alternative to perchlorethylene & nPB

-

-

-

PROMOCLEAN TP 186B

- Removing varnish, resins, paints, glues, inks & lacquers

- Aqueous immersion & co-solvent process

- Very low environmental impact

-

-

TOPKLEAN MC 1007D

- Heavy contaminants removal

- Mono-solvent, co-solvent or spray process

- Environmental friendly alternative to perchlorethylene & nPB

-

PROMOSOLV 70

- Removal of a wide range of contaminants

- Vapor phase process

- Very low GWP: 96

- 3M Novec 71DE, Novec 72DE, Novec 73DE replacement

-

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.