Polishing Compounds Removal

Solutions for difficult to remove substances like polishing paste, diamond polishing liquid, polymers & resins without harming the substrates they have to removed from. Suited for your desired process and formulated to meet today’s environmental regulations and beyond.

Polishing Compounds Removal Solutions for Every Surface Finishing Challenge

Effective removal of polishing compounds is critical to prevent surface contamination, ensure optimal adhesion, and maintain the integrity and performance of high-precision components across advanced manufacturing processes.

Select subsegment :

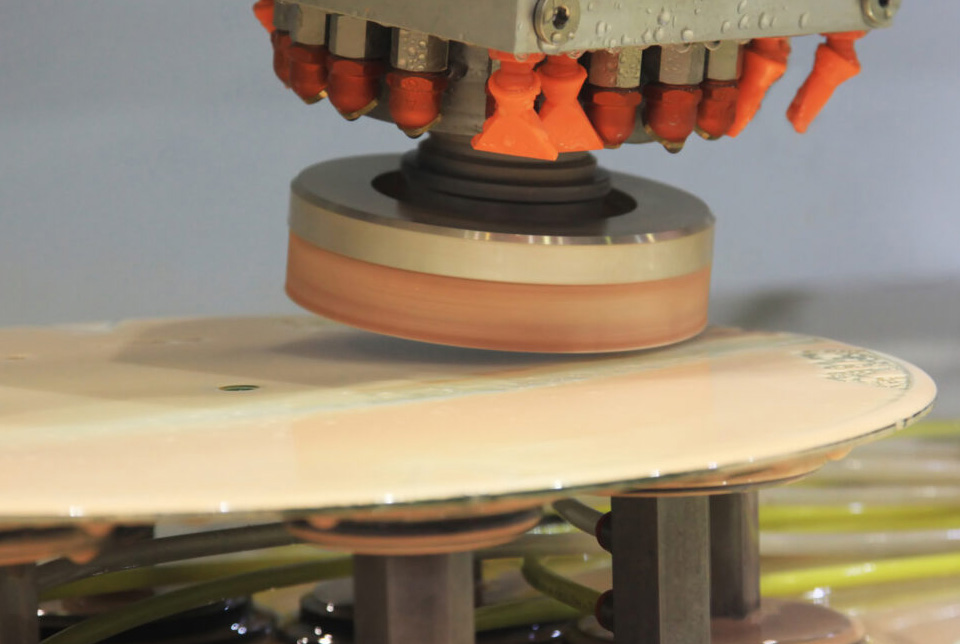

Diamond Polishing Slurry Removal

Cleaning diamond polishing slurry is essential in industries to maintain optimal tool performance, prevent material buildup, and ensure the accuracy and finish of precision surfaces—challenges for which INVENTEC provides advanced, high-efficiency cleaning solutions designed for demanding industrial applications.

Removing stubborn residues of diamond polishing slurry and other diamond polishing compounds from precision-machined parts is a critical challenge that demands advanced, high-performance cleaning solutions…

Read more

Polishing Paste Removal

The cleaning of polishing paste in industries is important to ensure the removal of contaminants, enhance product quality, and maintain the efficiency and longevity of equipment used in polishing and finishing operations; INVENTEC offers effective cleaning solutions tailored to meet these industrial requirements.

Effectively removing stubborn polishing paste and polishing compounds demands customized cleaning solutions that protect sensitive alloys, prevent corrosion, and deliver superior removal of polish residue for optimal part quality and performance…

Learn more Download the flyer

Discover Our Polishing Residue Remover for Heavy Contaminants!

PROMOCLEAN TP 125

- Removal of burnt residues, oxides, polishing pastes, heavy greases & oil

- Aqueous immersion process

- Compatible with ferrous alloys & copper

- Non-toxic & no CMR substances

Polishing Compounds Removal

Industrial Cleaning Solutions

Frequently Asked Questions (FAQ)

Why is polishing residue removal crucial in precision industries?

Residues from polishing pastes and diamond polishing liquids can compromise surface quality, adhesion and functionality. In optics, semiconductors and medical devices, even microscopic contamination can lead to defects or failures.

Which types of polishing residues are the hardest to remove?

Diamond polishing liquids and resins are among the most difficult to eliminate. They adhere strongly to surfaces and require specialized cleaning solutions without damaging the substrate.

How do INVENTEC’s solutions facilitate the removal of challenging polishing pastes?

INVENTEC offers d edicated cleaning solvents capable of dissolving and dispersing stubborn residues. These formulations are engineered to be safe for delicate substrates like sapphire, silicon wafers or medical-grade alloys.

Can these solutions be used on sensitive substrates without damaging them?

Yes. Modern formulations are optimized to remove polishing residues while protecting fragile materials such as optical glass, aluminium alloys and ceramics. They prevent microcracking, corrosion or surface roughness.

What are the advantages of removing residues before a coating or bonding step?

Clean surfaces ensure maximum adhesion and coating durability. Any polishing residue can act as a barrier, reducing bond strength and compromising long‑term reliability.

How do these products ensure environmental compliance?

INVENTEC’s solutions exceed current environmental standards such as REACH and RoHS. They reduce VOC emissions, toxicity and waste generation while maintaining high cleaning efficacy.

Which industries benefit most from polishing‑paste removal solutions?

Industries such as watchmaking, precious metalwork, optics and medical devices rely on polishing‑paste removal to achieve defect‑free surfaces, enhance performance and meet rigorous quality standards.

Can cleaning of diamond polishing liquid residues be automated?

Yes, via aqueous immersion processes equipped with ultrasound, ensuring consistent removal of abrasive residues in high volume production lines.

What performance benefits are achieved with these advanced solutions?

Benefits include rapid residue removal, reduced downtime, compatibility with sensitive substrates and residue‑free surfaces. This improves productivity, product quality and long‑term reliability.

How does INVENTEC support its clients to optimize polishing‑paste removal?

INVENTEC provides laboratory testing, process customization and technical support to tailor solutions to clients’ needs. This ensures safe removal of polishing compounds while maximizing efficiency and durability.

Polishing Compounds Removal: Effective Cleaning of Advanced Substrates

Polishing compounds removal solutions are essential in industrial cleaning when residues of polishing pastes, diamond polishing liquids, polymers, and resins must be eliminated without damaging metallic, ceramic, or plastic substrates.

These solutions are formulated for precision cleaning processes, including immersion, spray, and ultrasonic techniques, ensuring the complete removal of difficult-to-clean residues while complying with environmental regulations and sustainability standards.

Applications are found in the automotive, aerospace, medical devices, watchmaking, and jewelry industries, where surface quality, functional integrity, and reliability are critical for safety and performance.

Benefits & Applications

Key benefitsPolishing compounds removal safely eliminates residues such as polishing pastes, diamond liquid suspensions, polymers, resins, and waxes. These residues are often difficult to clean and may interfere with subsequent processes or affect the performance of sensitive components. Dedicated compounds removal processes protect substrates while ensuring a high level of cleanliness.

Technical aspectsPolishing compounds removal can be performed with aqueous, solvent, or hybrid solutions adapted to different materials and processes. These advanced formulations enable diamond slurry cleaning, polishing paste removal, and polymer and resin removal without causing corrosion, discoloration, or substrate degradation. Compliance with current and future environmental regulations is a central point of these processes.

ApplicationsPolishing compounds removal is essential in watchmaking, jewelry, electronics assembly, semiconductor packaging, optical device cleaning, and precision mechanics. These solutions are particularly suitable for wax stripping in microelectronics, resin removal in encapsulated devices, and for preparing surfaces for subsequent treatments such as coating, bonding, or brazing.

Polishing compounds removal in watchmaking and jewelry

In watchmaking and jewelry, removing polishing residues from metallic components and precision parts ensures a flawless surface finish, durability, and the value of luxury products.

Polishing compounds removal in the automotive industry

In automotive manufacturing, removing polishing residues from metallic components and precision plastic parts ensures an optimal surface finish, durability, and coating adhesion.

Polishing compounds removal in aerospace and defense

For aerospace components, removing diamond polishing liquids and other residues from titanium or aluminum alloys is crucial to maintain surface integrity and mission-critical reliability.

Polishing compounds removal in the medical industry

In medical devices, removing polishing pastes and resins from stainless steel instruments or precision polymer components is essential to ensure patient safety and device performance.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.