Rinsing & Drying solvents

Environmental friendly solvents for rinsing in a Co-solvent process for cleaning of electronic and mechanical parts. Dedicated range for water removal processes as a faster and more environmental alternative for drying by hot air.

Rinsing & Drying Solvent Solutions for Optimal Manufacturing Results

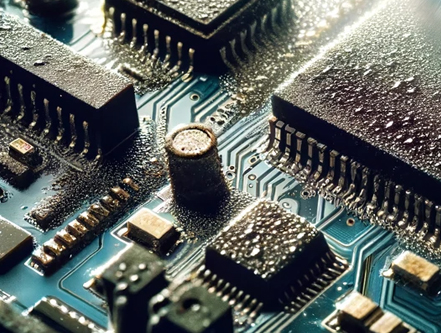

Effective rinsing and drying with advanced solvents is critical for eliminating residues and moisture from components, ensuring superior cleanliness, preventing corrosion, and enhancing reliability and performance across electronics, semiconductor, and precision manufacturing processes.

Select subsegment :

Rinsing solvents

Rinsing solvents play a critical role in industrial cleaning within the automotive and aerospace sectors by ensuring the removal of contaminants and residues—essential for surface integrity, coating adhesion, and component performance; with INVENTEC providing advanced rinsing solvent solutions tailored to meet demanding requirements.

Discover how our sustainable rinsing agents and advanced solvent cleaners enhance co-solvent processes by delivering high-performance results in mechanical cleaning, electrical contact cleaning, and precision solvent rinse applications…

Learn more

Drying Solvents

Drying solvents are essential in industrial cleaning processes for sectors like automotive and aerospace, and INVENTEC provides advanced solutions that ensure rapid evaporation without residue, enabling faster processing and preventing corrosion or contamination on high-precision components.

Discover a faster, energy-efficient, and sustainable alternative to hot air drying with Inventec’s innovative drying solvent technology, ideal for mechanical cleaning, >electronic cleaning, and precision applications…

Learn more

Discover our PFAS free cleaning solvent!

PROMOSOLV NEO A1

- Light oil & particles removal / rinsing & drying

- Vapor phase, co-solvent, flushing & drying process

- No GWP & PFAS frees

This is a product

Rinsing & Drying Solvents

Industrial Cleaning Solutions

Frequently Asked Questions (FAQ)

What is the role of rinsing solvents in electronic and semiconductor cleaning?

Rinsing solvents are used after the main cleaning step to remove residual detergents, dissolved contaminants, and moisture. They ensure particle-free and residue-free surfaces, critical for electronic assemblies and semiconductor devices where even trace contaminants can affect reliability.

How does a co-solvent process improve cleaning efficiency?

A co-solvent process combines a high-performance cleaning solvent with a rinsing solvent. The cleaning solvent dissolves heavy contaminants, while the rinsing solvent displaces residues and water. This method provides enhanced cleaning precision, reduced drying times, and compatibility with sensitive materials.

Why is drying solvent preferred over hot air drying?

Drying solvents rapidly displace and remove water from component surfaces due to their low surface tension and fast evaporation rate. Compared to hot air drying, they reduce thermal stress, prevent watermarks, and increase throughput while consuming less energy.

What properties make a rinsing or drying solvent effective?

Key properties include low viscosity, low surface tension, high volatility, and strong compatibility with polymers, metals, and coatings. These characteristics ensure rapid water displacement and residue-free drying without damaging sensitive substrates.

Are rinsing and drying solvents safe for delicate semiconductor wafers?

Yes. Modern rinsing and drying solvents are engineered to protect sensitive wafers and advanced packaging. Their low ionic content and controlled evaporation prevent contamination, micro-cracking, or corrosion during the drying phase.

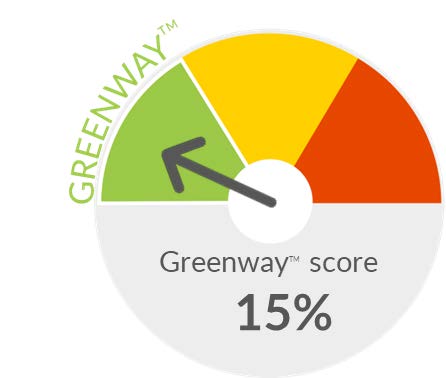

How do rinsing solvents contribute to environmental sustainability?

Compared to traditional hot air drying or high-VOC solvents, modern rinsing solvents reduce energy consumption, minimize emissions, and can often be recycled in closed-loop systems. INVENTEC develops rinsing and drying solvents specifically designed to align with eco-regulations such as REACH and RoHS.

What are the advantages of using INVENTEC’s co-solvent process?

INVENTEC offers environmentally friendly rinsing solvents dedicated to co-solvent cleaning of electronic and mechanical parts. The process improves cleaning efficiency, accelerates drying, and ensures consistent performance while reducing environmental impact.

How do drying solvents reduce watermarks and residues on components?

By lowering surface tension and promoting uniform evaporation, drying solvents eliminate trapped water droplets and streaks. This ensures optically clean and residue-free surfaces, which is critical for optical sensors, semiconductor wafers, and fine-pitch electronics.

Can rinsing and drying solvents be integrated into automated cleaning lines?

Yes. Rinsing and drying solvents are compatible with ultrasonic and vapor phase equipment. They can be seamlessly integrated into automated systems for high-volume production, improving throughput while maintaining process control.

How does INVENTEC ensure performance and reliability of its drying solvents?

INVENTEC supports customers with laboratory validation, process optimization, and residue analysis. This guarantees that drying solvents meet industrial requirements for electronics and semiconductor manufacturing, while ensuring long-term device reliability.

Rinsing & Drying Solvents: Eco‑friendly Solutions for Electronic & Mechanical Components

Rinsing and drying solvents are essential for the post‑treatment of both electronic and mechanical components. Modern co‑solvent processes allow efficient removal of residues, fluxes, and contaminants while minimizing environmental impact.

Using environmentally friendly solvents ensures compliance with regulatory standards while maintaining a high level of cleanliness for sensitive parts. These solutions are crucial in sectors where precision and reliability are critical, including automotive electronics, aerospace systems, medical devices, and precision mechanical engineering such as Swiss watchmaking.

Advantages & Applications

Main advantagesRinsing and drying solvents provide effective cleaning of electronic and mechanical components, allowing quick removal of water and contaminants. These eco‑friendly solvents reduce energy consumption, speed up processes and offer a safer alternative to hot‑air drying.

Technical aspectsOur rinsing and drying solvents are formulated for co‑solvent cleaning processes and optimized for parts sensitive to water. They provide a controlled evaporation rate, excellent surface wettability, and compatibility with various electronic assemblies, power modules, and delicate mechanical parts. Their low VOC content and reduced flammability ensure compliance with current and future environmental regulations.

ApplicationsThese rinsing and drying solvents are widely used in automotive electronics, aerospace and defense, medical device assemblies, and precision micromechanics like watchmaking. Ideal for water removal processes, co‑solvent cleaning cycles, and rapid drying of PCBs, power electronics and delicate mechanical components, they improve process efficiency while ensuring the reliability and safety of components.

Eco Rinsing & Drying in Automotive Electronics

In electric and hybrid vehicles, rinsing and drying solvents remove flux residues and contaminants from power modules, batteries, and sensors. Eco solvents reduce emissions while ensuring reliability and optimal performance.

Rinsing & Drying for Aerospace & Defense

High‑precision avionics require co‑solvent rinsing to remove flux and particulates from avionics modules, radars, and satellite components. Eco solvents ensure signal integrity and component reliability under extreme environments.

Cleaning Medical Devices with Rinsing & Drying

In medical electronics, rinsing and drying remove flux and contaminants from PCBs, diagnostic modules, and sensors. Eco solvents maintain cleanliness standards without compromising patient safety.

High‑Precision Rinsing for Micromechanics

Micromechanical components, especially in the Swiss watchmaking industry, require residue‑free cleaning to ensure perfect operation. Inventec’s rinsing and drying solvents offer fast evaporation and spotless cleanliness without affecting delicate materials such as precious alloys.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.