PCB Defluxing & Cleaning

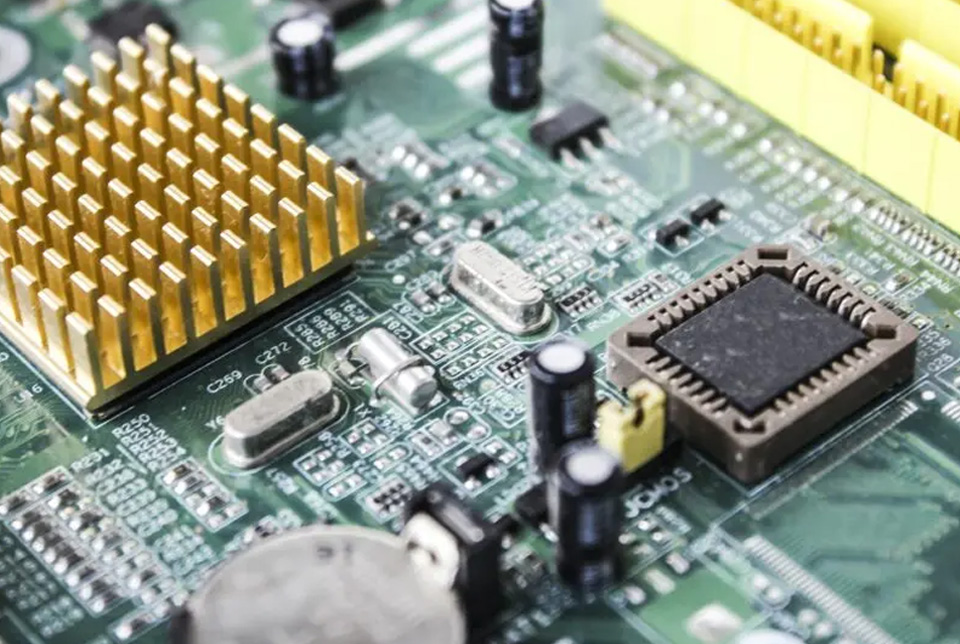

Our advanced PCB defluxing and cleaning solutions are designed to deliver precise, efficient removal of flux residues, ensuring superior adhesion, enhanced component reliability, and consistent electrical performance, perfect for high-quality electronics assembly and demanding PCB cleaning applications.

Advanced PCB Defluxing & Electronics Cleaning Solutions

Effective PCB defluxing is essential to ensure long-term performance and reliability of electronic assemblies. INVENTEC’s high-performance flux cleaning solutions remove post-soldering residues that could impair coatings, cause corrosion, or lead to failures.

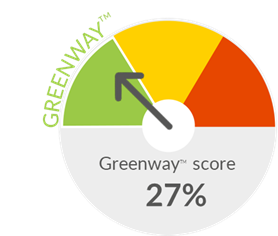

As electronics evolve with tighter spaces and low stand-off components, cleaning becomes more complex. INVENTEC addresses these challenges with eco-designed industrial cleaning solutions, optimized for no-clean flux residues and sensitive parts.

With 15+ years of expertise, INVENTEC provides tailored products and processes for PCB cleaning, semiconductor cleaning, and leadframe defluxing, including our efficient co-solvent cleaning process using Topklean and Hydrofluoroethers.

Why Choose INVENTEC?

- Solvent and aqueous-based electronics cleaning options

- Efficient removal of flux and ionic residues

- Solutions for sensitive, miniaturized components

- Compliance with environmental and safety standards

Our Top-performing defluxing products

Explore some of our top-performing defluxing products for PCB and semiconductor cleaning:

| Process | Method | Product Solution |

|---|---|---|

| Solvent | Co-Solvent |

CLEANING SOLVENT: |

|

RINSING SOLVENT: |

||

| Mono-Solvent (Vapor Phase) |

|

|

| Vacuum |

|

|

| Aqueous | Spray in Air |

|

| Spray in Line |

|

|

| Immersion Jets |

|

|

| Immersion Ultrasonics |

|

|

| Manual |

|

This list is not exhaustive. For more products or tailored advice, please contact us.

Key PCB Defluxing & Cleaning Processes:

- Co-solvent: Topklean cleaners + Hydrofluoroether rinses

- Mono-solvent vapor phase: One-step solvent cleaning

- Aqueous spray: Batch or inline spray systems

- Aqueous immersion: With agitation or ultrasonics

- Manual cleaning: Spot cleaning for small batches

INVENTEC delivers reliable, high-performance solutions for modern PCB defluxing, electronics, and semiconductor cleaning processes, adapting them to your specific challenges to ensure optimal results at every step.

Explore More Cleaning Solutions Read FAQ

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Showing all 15 results

-

-

PROMOSOLV 70ES

- Removal of flux residues

- Vapor phase process

- Balanced performance

- 3M Novec 71DA, Novec 72DA replacement

-

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

-

-

-

-

-

-

-

-

-

-

-

Discover our Powerful All-in-One Industrial Cleaning Solution!

QUICKSOLV DEF 90

- Multi-purpose cleaner

- Manual cleaning

- Non-flammable

PCB Defluxing

Electronic & Semiconductor Cleaning Solutions

Frequently Asked Questions (FAQ)

What is PCB defluxing and why is it important?

PCB defluxing is the process of removing solder flux residues from printed circuit boards after soldering. Proper defluxing is crucial to prevent corrosion, electrical shorts, and to ensure long-term reliability of electronic assemblies.

What types of flux residues require cleaning?

Flux residues vary depending on flux type—rosin-based, water-soluble, or no-clean fluxes. Water-soluble fluxes require thorough cleaning, while no-clean fluxes often leave benign residues that may not need removal.

Which cleaning methods are used for PCB defluxing?

Common cleaning methods include aqueous cleaning with detergents, solvent cleaning using specialized chemicals, and semi-aqueous processes. Ultrasonic and spray-in-air technologies enhance cleaning efficiency.

How does defluxing improve PCB performance?

Removing flux residues eliminates potential ionic contaminants and residues that cause corrosion or electrical leakage, ensuring optimal electrical performance and increasing product lifespan.

Are no-clean fluxes always safe to leave on PCBs?

No-clean flux residues are formulated to be non-corrosive and non-conductive, but in some high-reliability or sensitive applications, defluxing may still be recommended to guarantee performance.

What factors influence the choice of defluxing chemicals?

Factors include flux type, PCB materials, environmental regulations, cleaning equipment, and compatibility with components. INVENTEC provides tailored cleaning chemistries optimized for various flux residues and board materials.

Can defluxing damage sensitive semiconductor components?

When using appropriate cleaning agents and controlled processes, defluxing is safe. It’s important to select compatible cleaning chemistries that do not degrade semiconductor materials or delicate PCB finishes.

What are the environmental considerations for PCB defluxing?

Many defluxing agents are designed to be low-VOC, biodegradable, and compliant with environmental standards. INVENTEC emphasizes sustainable cleaning solutions to meet industry regulations.

How is cleaning effectiveness verified after defluxing?

Inspection techniques include ionic contamination testing, visual inspection under UV light, and electrical testing to confirm the removal of residues and ensure PCB cleanliness.

Does INVENTEC offer PCB defluxing and cleaning solutions?

Yes, INVENTEC Performance Chemicals supplies a wide range of defluxing and cleaning products specifically formulated for electronics and semiconductor industries, ensuring high efficiency and reliability in cleaning processes.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.