PROMOSOLV 70ES

Removal flux residues and contaminants

- Removal of flux residues

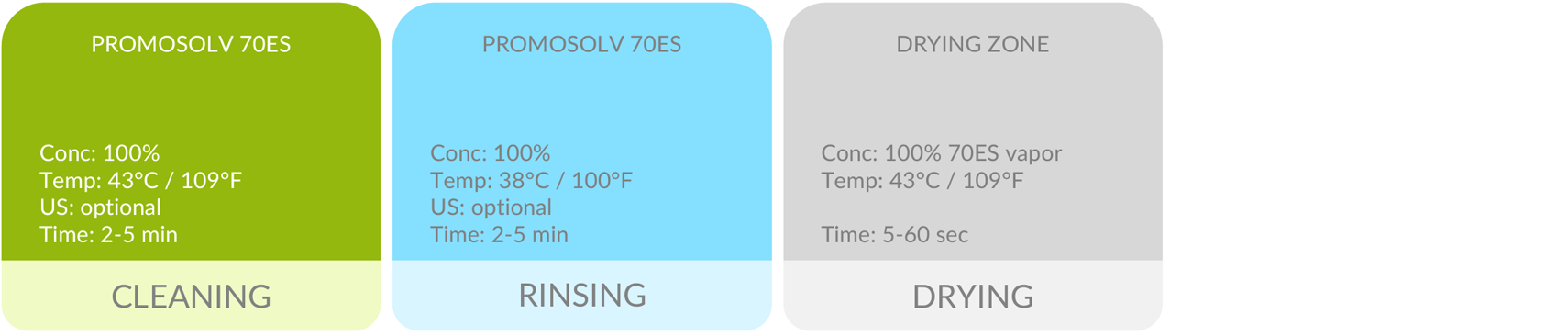

- Vapor phase process

- Balanced performance

- 3M Novec 71DA, Novec 72DA replacement

PROMOSOLV 70ES

Is developed as a drop-in replacement for trichlorethylene, NPB and other solvent. While reducing substantially the HSE impact, the defluxing power is at an equivalent level.

It is dedicated for removing reflowed flux residues and other contaminants on PCBA’s, Power modules, lead frames, BGA’s, PoP or SIP applications & LED assemblies. Its low surface tension allows very well cleaning and rinsing under low stand-off components and difficult to reach spaces. It has very good compatible with all metals, including very sensitive ones and also with most plastics & elastomers, however recommended to validate before use.

PROMOSOLV 70ES is formulated with safety in mind. Its composition gives excellent flammability suppression properties, which provides a very high stability when used in an equipment. Some products in the market may loose their flammability suppression compound due to evaporation when used in an equipment.

This product also exists in a recycled version (made from recycled solvent) under the name PROMOSOLV 70ES T.

PROMOSOLV 70ES is a drop-in replacement for 3M Novec 71DA and Novec 72DA which are scheduled to be phased out voluntarily by end 2025. Click on the link for more info on the announcement of 3M Novec phase out.

This is not a product

Although fully in line with safety & environmental regulations, this product doesn`t match our strict criteria to be labelled as a Greenway product.

LOOKING FOR A MORE SUSTAINABLE SOLUTION?

GREENWAY ALTERNATIVE

- We currently don`t have a Greenway alternative but our target is to develop one in the near future. In case you want us to prioritize the development of a Greenway alternative, do not hesitate to contact us.

Benefits

PERFORMANCE

- Thermally and chemically stable in use

- The very low surface tension allows deep rinsing under low stand-off components

- Short cleaning, rinsing and drying times

COST

- Continuous recycling in equipment for a long bath-life

- Can be returned for recycling and re-use

- The relative high boiling point reduces risk of solvent drag, so limiting consumption

HSE

- Very low toxicity

- No Ozon Depletion Potential (ODP)

- Low Global Warming Potential (GDP): 93

- Non-flammable& no flashpoint