Tinning Flux Solutions

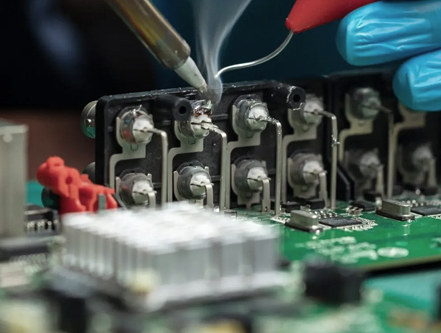

Our advanced range of tinning flux solutions is specifically formulated to ensure excellent wetting, uniform solder coverage, and reliable performance in cable tinning and soldering applications, meeting the high standards of modern electronic manufacturing.

High-Performance Tinning Flux for Cable Assembly & Lead-Free Soldering

Reliable cable assembly requires a dependable tinning flux to promote clean solder adhesion, superior wetting, and consistent coverage. Whether in high-volume manufacturing or precision rework, the right flux tinning solution directly impacts solder quality and performance.

Inventec’s ECOFREC™ range of tinning soldering flux is specifically designed to remove oxides and prepare metal surfaces for optimal solder flow, ensuring clean, conductive joints. With options for lead free tinning flux and water soluble tinning flux, these solutions support RoHS compliance, reduce residues, and enhance long-term reliability across various industries.

Engineered for efficiency and versatility, ECOFREC™ tinning flux products are ideal for both manual and automated cable tinning. They offer excellent compatibility with copper wires, multi-stranded conductors, and a variety of soldering techniques, making them a preferred choice for cable harness assembly, PCB repair, and critical aerospace applications.

Key Benefits of Inventec Tinning Flux Solutions:

- Enhanced wetting and spreading for uniform tinning

- Strong oxide removal, even at lower temperatures

- Optimized for copper wires and stranded conductors

- Available in lead-free and water-soluble options

INVENTEC’s ECOFREC™ tinning fluxes ensure reliable cable tinning with excellent solderability, minimal residue, and strong environmental compliance across all soldering methods.

See Other Soldering Flux Processes Read FAQ

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Showing all 10 results

-

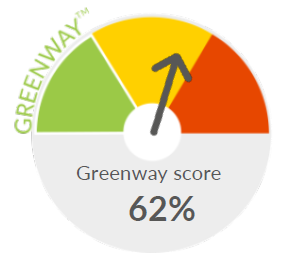

ECOFREC 205

- Solvent based no-clean liquid flux

- Wave & selective soldering

- Excellent wetting on all board finishes

-

-

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

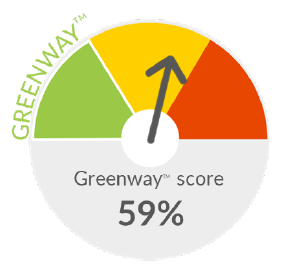

ECOFREC 303E

- Water-based no-clean liquid flux

- Wave & selective soldering

- Excellent wetting & High electronic reliability

-

ECOFREC 303

- Waterbased VOC free, no-clean liquid flux

- Soldering either with air or nitrogen controlled atmosphere

- High reliability

-

ECOFREC 202

- Solvent based no-clean liquid flux

- Wave & selective soldering

- High reliability and no visual residues

-

-

ECOFREC DILUENT 1

- Flux thinner for solvent based fluxes.

- Adjust density due to evaporation.

- Made from high purity solvents.

-

ECOFREC DD6

- Solvent based rosin liquid flux

- Wave -, selective spray, foam or manual brush process

- high reliability & easy to clean

-

ECOFREC CMA 155

- Solvent based high rosin liquid flux

- Suitable for all fluxing processes

- Very good wetting & easy to clean

Discover Our Low-Residue No-Clean Flux for Superior Wave & Selective Soldering Performance!

ECOFREC 200

- Solvent based no-clean liquid flux

- Wave & selective soldering

- Excellent wetting & high reliability

Tinning Flux

Soldering Fluxes Solutions

Frequently Asked Questions (FAQ)

What is tinning flux?

Tinning flux is a specialized flux designed to promote uniform solder coating (tinning) on component leads, wires, and PCB pads. It removes oxides and enhances wetting to ensure consistent solder coverage and reliable joint formation.

What is tinning used for in electronics assembly?

Tinning is used to pre-coat metal surfaces with solder to prevent oxidation, improve solderability, and ensure strong, conductive connections. It's commonly applied to wires, component leads, and reworked pads before final soldering.

How does tinning flux differ from standard soldering flux?

While both promote wetting, tinning flux is typically more aggressive in removing oxides and preparing surfaces for full solder coverage. It’s optimized for immersion or brush application, and for situations requiring complete tinning of exposed metal.

What are the most common applications of tinning flux?

Tinning flux is used in wire tinning, lead preparation for through-hole components, pad re-tinning during PCB repair, and for deoxidizing metal finishes such as copper, brass, or nickel. INVENTEC provides tailored formulations for these processes.

What types of tinning flux are available?

There are no-clean, rosin-based, and water-soluble tinning fluxes. Selection depends on whether cleaning is required after tinning, the metals involved, and the application method. INVENTEC offers all major types to suit industrial soldering environments.

How is tinning flux applied?

Tinning flux can be applied by dipping, brushing, spraying, or with foam fluxers, depending on the component or wire geometry. Proper application ensures uniform solder coverage and minimal residue.

Is cleaning necessary after using tinning flux?

It depends on the flux type. No-clean tinning fluxes may not require removal if residues are minimal and non-corrosive. Water-soluble and more aggressive rosin-based fluxes typically require thorough cleaning after tinning. INVENTEC provides guidance based on your flux choice.

Can tinning flux be used with lead-free solders?

Yes. Modern tinning fluxes are fully compatible with lead-free alloys such as SAC305 or SnCu. INVENTEC offers lead-free-compatible tinning fluxes that deliver consistent wetting and performance across a range of metals.

What metals can be treated with tinning flux?

Tinning flux is effective on copper, brass, nickel, and tinned surfaces. It helps remove oxides and promotes uniform solder adhesion, even on slightly tarnished or aged surfaces. Always ensure flux compatibility with the base metal and solder alloy.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

Do you need cleaning or coating after soldering? We provide FREE-OF-CHARGE cleaning or coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. It is also possible to attend trials in person.