Conformal Coatings

Heat & UV cured conformal coatings & related thinners from our partner ABchimie™. Latest development are the UV LED cured coatings which have no VOC, are non flammable and will speed up your process significaly.

Select subsegment :

ABchimie & Inventec partnership

INVENTEC has been a long-time partner, playing a key role in making ABchimie products available to customers around the world, alongside our high-quality electronic soldering and cleaning solutions, ensuring global reach and exceptional service.

ABOUT ABchimie

ABchimie’s conformal coating are great PCB protection solutions, specially developed with sustainability in mind. Conformal coatings ensure protection of PCBA’s from unwanted influences of the environment. They increase reliability of the electronics and extending the working life of the devises they are placed in.

ABchimie’s conformal coating are great PCB protection solutions, specially developed with sustainability in mind. Conformal coatings ensure protection of PCBA’s from unwanted influences of the environment. They increase reliability of the electronics and extending the working life of the devises they are placed in.

Coatings are certainly beneficial for electronics exposed to harsh environment such as salt spray, high humidity, fluctuating & high temperatures, solvent, dust … These environmental conditions can cause damage as corrosion, current leakage and premature failure.

ABOUT INVENTEC PARTNERSHIP

INVENTEC has been a long time partner to make ABchimie products available around the world, along side our electronic soldering & cleaning solutions. Our worldwide Technical Support team is well established to help you with the implementation of the coatings in your process.

INVENTEC is an authorised distributor of ABchimie products in the following countries:

- Europe: Germany – Hungary

- America: USA – Mexico – Brazil

- Asia: China – Malaysia – Singapore

DOCUMENT SOURCES

Read moreHeat cured

conformal coatings

Heat cured conformal coatings are already around for some time and polymerize or in other words get solid by exposure to heat.

The temperature and time needed to have a touch dry coating depends on the nature of the coating (PU, Acrylic or Silicon based). The full curing usually is established after several days at ambient temperatures.

The temperature and time needed to have a touch dry coating depends on the nature of the coating (PU, Acrylic or Silicon based). The full curing usually is established after several days at ambient temperatures.

ABchimie AVR80 BA is the green alternative and a favorite choice of customers to replace conformal coatings which have some toxic elements in their formulation. The solvent used in this formulation is specifically chosen and designed to avoid toxic exposure to people in the workplace.

ABchimie has many more products in their portfolio. We only display here the most common ones. You can refer to the ABchimie website (www.abchimie.com) or ask us for more advice.

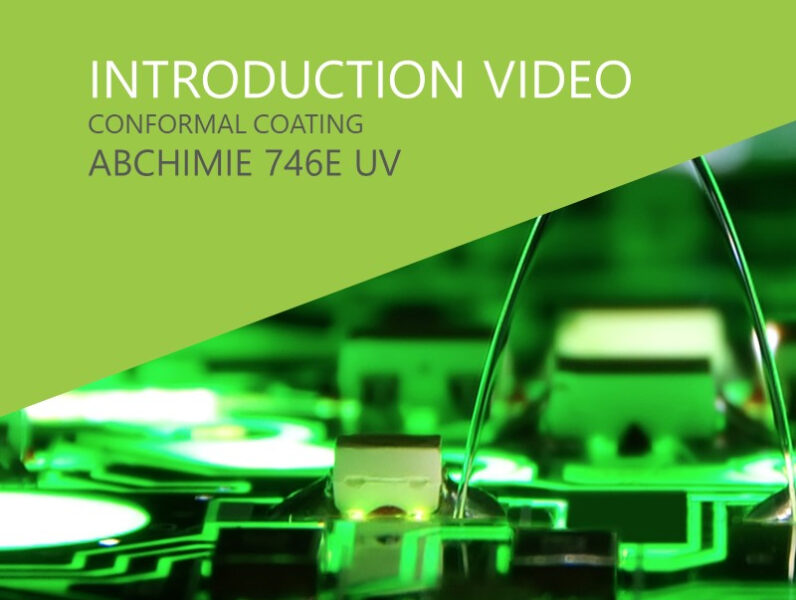

Read moreUV cured

conformal coatings

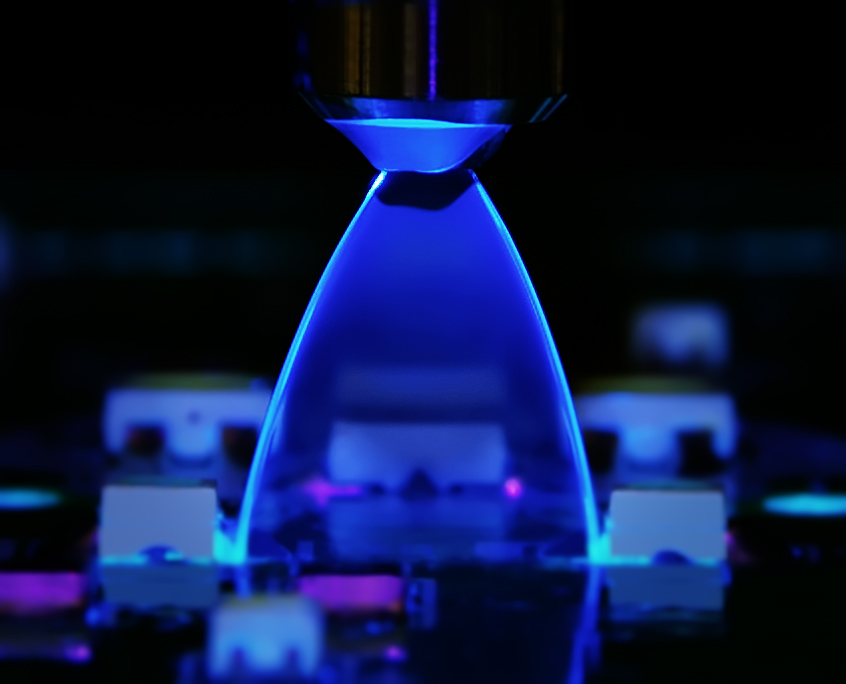

UV-cured coatings offer a faster curing process than heat-cured alternatives, are non-flammable, and contain no VOCs, making them an ideal solution to address VOC regulations and taxes.

The lastest innovation from ABchimie is ABchimie 746E UV LED. This coating is cured with UV LED instead of traditional used UV mercury lamps. This provides a more stable process, less energy consumption and less heat generation. All UV cured coatings from ABchimie have a dual curing mechanism. This means that in shadow area’s (where the UV light can’t reach) the curing is done by moisure taken from the air.

The lastest innovation from ABchimie is ABchimie 746E UV LED. This coating is cured with UV LED instead of traditional used UV mercury lamps. This provides a more stable process, less energy consumption and less heat generation. All UV cured coatings from ABchimie have a dual curing mechanism. This means that in shadow area’s (where the UV light can’t reach) the curing is done by moisure taken from the air.

ABchimie has many more products in their portfolio. We only display here the most common ones. You can refer to the ABchimie website (www.abchimie.com) or ask us for more advice.

DOCUMENT SOURCES

Read moreTechnical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning and coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.