Stripping & Deoxidation

Removal of oxides & mineral residues from various metals and alloys, according to your desired process.

Stripping & Deoxidation Solutions for Metals and Alloys

Stripping and deoxidation are essential industrial cleaning processes in sectors such as automotive, aerospace, and electronics manufacturing. They ensure optimal surface preparation, enhancing adhesion, corrosion resistance, and the overall durability of coatings and treatments.

The presence of oxides, corrosion, and mineral residues on sensitive metals can lead to malfunctions, reduced quality in downstream processes like painting, marking, varnishing, or gluing, and even cause mechanical failure. Complete corrosion removal is therefore critical for maintaining high performance and reliability of finished components.

Traditional deoxidation solutions based on mineral acids (hydrochloric, nitric, sulfuric) require restrictive, costly safety measures and generate significant environmental risks. Similarly, phosphoric acid-based stripping products contribute to resource depletion and aquatic pollution through eutrophication.

INVENTEC offers innovative alternatives with a new generation of stripping and deoxidizing fluids, free from mineral compounds and phosphorus. These advanced industrial cleaning solutions combine excellent deoxidation efficiency with improved safety, sustainability, and regulatory compliance.

Key Benefits of INVENTEC Stripping & Deoxidation Solutions:

- Effective Oxide & Residue Removal: Reliable stripping of corrosion and mineral deposits for metals and alloys.

- Safe & Sustainable Chemistry: Alternatives without mineral acids or phosphorus, reducing hazards and environmental impact.

- Improved Process Performance: Enhances adhesion, coating durability, and corrosion resistance.

- Versatile Applications: Suitable for automotive, aerospace, electronics, and precision metal industries.

INVENTEC provides advanced stripping and deoxidation solutions that ensure surface integrity, long-term protection, and compliance with environmental standards. For temporary protection, explore our oil removal solutions. For extended durability, discover our coatings range.

See Other Cleaning Solutions Discover our guide Read FAQ

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Showing all 10 results

-

PROMOCLEAN TP 188

- Stripping of cured or polymerised substances

- Aqueous immersion, flushing & co-solvent process

- Environmental friendly substitution for NMP & chlorinated solvents

-

-

PROMOSOLV NEO A1

- Light oil & particles removal / rinsing & drying

- Vapor phase, co-solvent, flushing & drying process

- No GWP & PFAS free

- 3M Novec 7100 replacement

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

-

PROMOCLEAN TP 186B

- Removing varnish, resins, paints, glues, inks & lacquers

- Aqueous immersion & co-solvent process

- Very low environmental impact

-

PROMOSOLV NEO B1

- Removal of a wide range of contaminants

- Vapor phase process

- PFAS free & no GWP

- 3M Novec 71DE, Novec 72DE, Novec 73DE, and Novec 8200 replacement

-

PROMOCLEAN DEWAX+

- Removing wax, light oxides & mineral residues

- Aqueous immersion process with ultrasonics

- Perfect phase separation & sustainable

-

PROMOCLEAN DISPER 22

- Removal of grease, heavy oils, burn-in residues & oxides

- Aqueous spray processes

- Compatible with ferrous alloys

-

PROMOCLEAN TP 178

- Removing oxides, mineral residues & diamond liquid polishing

- Aqueous immersion process with ultrasonics

- Substitute for phosphoric acid based cleaners

-

Discover our Stripping and Deoxidation Solution for Ferrous Alloys!

PROMOCLEAN DISPER 22

- Removal of grease, heavy oils, burn-in residues & oxides

- Aqueous spray processes

- Compatible with ferrous alloys

- Non-toxic & no CMR substances

Stripping & Deoxidation

Industrial Cleaning Solutions

Frequently Asked Questions (FAQ)

What is stripping and deoxidation in industrial cleaning?

Stripping and deoxidation refer to processes used to remove oxide layers, tarnish, scale, or mineral residues from metal surfaces. These treatments restore the base material’s original surface properties and prepare it for subsequent manufacturing steps.

Why are stripping and deoxidation important?

Oxides and mineral deposits can interfere with coating adhesion, soldering, welding, or bonding. Removing them ensures optimal surface quality, improves product reliability, and extends component lifespan.

Which materials require stripping and deoxidation?

Common materials include aluminum, copper, steel, brass, and various alloys used in aerospace, automotive, electronics, and precision engineering industries.

What methods are used for stripping and deoxidation?

Methods include chemical baths, acid-based treatments, alkaline cleaning, electrolytic processes, and mechanical abrasion. The choice depends on the metal type, oxide thickness, and required surface finish.

How is process effectiveness verified?

Techniques such as visual inspection, surface roughness measurement, contact angle analysis, and adhesion tests are commonly used to confirm proper oxide removal and surface preparation.

Can stripping and deoxidation be integrated into automated production lines?

Yes. Many stripping and deoxidation systems are compatible with automated lines, ensuring consistent treatment quality while reducing manual handling.

Does INVENTEC offer stripping and deoxidation solutions?

Yes. INVENTEC Performance Chemicals provides solutions formulated to efficiently remove oxides and mineral residues while protecting the integrity of the base metal.

Where can I get expert advice on selecting the right stripping and deoxidation process?

Industry specialists, including INVENTEC’s technical team, can assess your requirements, recommend suitable methods, and ensure compliance with environmental and safety regulations.

What are the main challenges in stripping and deoxidation?

Challenges include treating complex geometries, avoiding damage to sensitive surfaces, ensuring uniform oxide removal, and maintaining environmental and safety compliance.

How does stripping and deoxidation affect subsequent manufacturing processes?

Proper oxide removal improves coating adhesion, enhances soldering or bonding reliability, reduces the risk of component failure, and ensures higher quality in downstream assembly or finishing operations.

Stripping & Deoxidation Solutions: Removing Oxides and Mineral Residues

Stripping and deoxidation solutions are essential in industrial cleaning to remove oxides, scale, and mineral residues that form on metals and alloys during manufacturing, heat treatment, or storage. These contaminants can negatively impact surface quality, coating adhesion, and corrosion resistance.

Processes such as chemical stripping, acid deoxidation, electrolytic cleaning, and precision solvent cleaning can be applied depending on the substrate and the desired process. This ensures effective removal without damaging sensitive metallurgical properties.

Industries including automotive, aerospace, and medical devices rely on these solutions to maintain surface integrity, enable bonding, and meet strict quality standards.

Benefits & Applications

Key BenefitsStripping and Deoxidation processes are essential to achieve clean, reactive, and uniform surfaces on metals and alloys. Through the controlled removal of oxides and mineral residues, these treatments restore conductivity, improve surface adhesion, and extend component lifespan. An optimized stripping and deoxidation step helps ensure higher performance in demanding industrial applications.

Technical AspectsStripping and deoxidation methods can involve solvent-based formulations, aqueous cleaning agents, or advanced techniques like chemical immersion and plasma treatment. Each removal of oxides solution is designed to match the metal type and process requirements, ensuring that delicate substrates are treated effectively without damaging the underlying structure. Combining stripping and deoxidation enhances compatibility with coating, soldering, and bonding operations.

ApplicationsStripping and deoxidation are widely used in electronics assembly, semiconductor packaging, metal finishing, and precision engineering. The removal of oxides supports processes such as PCB preparation, wire bonding, and connector cleaning, while improving long-term durability and electrical performance. In aerospace, automotive, and medical industries, reliable deoxidation ensures compliance with strict safety and quality standards.

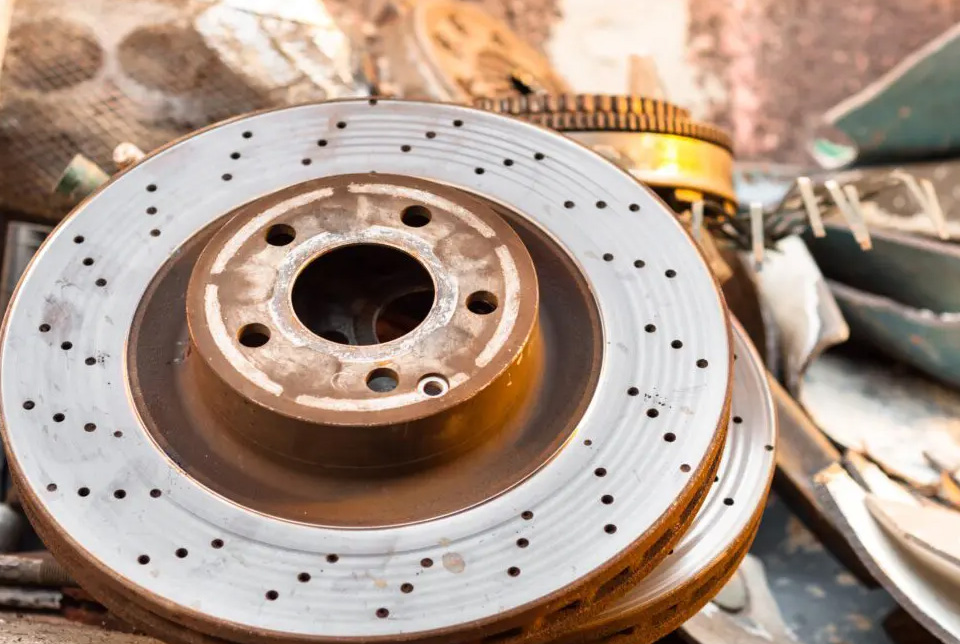

Stripping & Deoxidation in Automotive Industry

In the automotive industry, removing oxide layers and mineral deposits is essential before painting, plating, or welding. Surface preparation ensures durability, corrosion protection, and performance of components.

Stripping & Deoxidation in Aerospace and Defense

For the aerospace and defense sector, oxide removal is critical for lightweight alloys such as aluminum and titanium. Effective deoxidation enhances bonding and ensures compliance with stringent flight safety standards.

Stripping & Deoxidation in Medical Industry

In medical technology, deoxidation is vital for surgical instruments, implants, and stainless steel devices. Removing oxide films prevents contamination, improves biocompatibility, and ensures patient safety.

Showing all 10 results

-

PROMOCLEAN TP 188

- Stripping of cured or polymerised substances

- Aqueous immersion, flushing & co-solvent process

- Environmental friendly substitution for NMP & chlorinated solvents

-

-

PROMOSOLV NEO A1

- Light oil & particles removal / rinsing & drying

- Vapor phase, co-solvent, flushing & drying process

- No GWP & PFAS free

- 3M Novec 7100 replacement

-

-

PROMOCLEAN TP 186B

- Removing varnish, resins, paints, glues, inks & lacquers

- Aqueous immersion & co-solvent process

- Very low environmental impact

-

PROMOSOLV NEO B1

- Removal of a wide range of contaminants

- Vapor phase process

- PFAS free & no GWP

- 3M Novec 71DE, Novec 72DE, Novec 73DE, and Novec 8200 replacement

-

PROMOCLEAN DEWAX+

- Removing wax, light oxides & mineral residues

- Aqueous immersion process with ultrasonics

- Perfect phase separation & sustainable

-

PROMOCLEAN DISPER 22

- Removal of grease, heavy oils, burn-in residues & oxides

- Aqueous spray processes

- Compatible with ferrous alloys

-

PROMOCLEAN TP 178

- Removing oxides, mineral residues & diamond liquid polishing

- Aqueous immersion process with ultrasonics

- Substitute for phosphoric acid based cleaners

-

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.