Oxygen Parts Cleaning

Dedicated solutions for cleaning of parts in contact with pressurized oxygen to guarantee a safe use.

Oxygen Parts Cleaning Solutions for Safe & Reliable Systems

Cleaning oxygen system components is essential to ensure safe operation, prevent contamination, and eliminate ignition risks. INVENTEC offers reliable solutions for cleaning components in contact with oxygen, meeting strict safety and performance requirements. PROMOSOLV solvents comply with ASTM 2512, and BLUE GOLD is compatible according to ASTM G 72-8 and D24076 tests, with proper rinsing.

Residual oils, greases, or particles in oxygen systems can ignite and cause serious accidents. That’s why high precision cleaning is mandatory for all parts in contact with pressurized oxygen. INVENTEC solutions guarantee oxygen-compatible cleaning that meets the highest industry standards.

Compliance with oxygen safety standards requires rigorous process validation and monitoring. This includes RNV (residual non-volatile matter) analysis and particle count measurements to certify cleanliness. INVENTEC provides both qualified solvent and aqueous fluids as well as the expertise to design and implement validated cleaning processes for your operations.

Key Advantages of INVENTEC Oxygen Cleaning Solutions:

- Safe & Reliable: Prevents fire and ignition risks in oxygen systems.

- High Precision: Qualified cleaning validated by RNV & particle count analysis.

- Industry Proven: Dedicated solutions for aerospace, medical, industrial gas, and submarine sectors.

- Flexible Options: Solvent and aqueous fluids adapted to different oxygen applications.

INVENTEC provides oxygen-compatible cleaning solutions that ensure safety, precision, and full compliance with international standards. Backed by proven expertise and a wide range of qualified products, we help industries achieve reliable performance and extend the lifespan of critical oxygen equipment.

See Other Cleaning Solutions Discover our guide Read FAQ

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Showing all 8 results

-

PROMOSOLV NEO A1

- Light oil & particles removal / rinsing & drying

- Vapor phase, co-solvent, flushing & drying process

- No GWP & PFAS free

- 3M Novec 7100 replacement

-

-

PROMOSOLV NEO B1

- Removal of a wide range of contaminants

- Vapor phase process

- PFAS free & no GWP

- 3M Novec 71DE, Novec 72DE, Novec 73DE, and Novec 8200 replacement

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

PROMOSOLV 70

- Removal of a wide range of contaminants

- Vapor phase process

- Very low GWP: 96

- 3M Novec 71DE, Novec 72DE, Novec 73DE replacement

-

BLUE GOLD

- Degreasing & particle removal from equipment in contact with oxygen

- Aqueous spray & immersion process

- Passes ASTM F-495 and ARP 1775A norm

-

-

-

3M NOVEC 7100

- Light oil & particles removal / rinsing & drying

- Vapor phase, co-solvent, flushing & drying process

- Very low surface tension

Alternative: PROMOSOLV NEO A1

Discover Our Certified Cleaner for Oxygen-Contact Equipment Safety!

BLUE GOLD

- Degreasing & Particle removal from equipment in contact with oxygen

- Aqueous spray & immersion process

- Passes ASTM F-495 and ARP 1775A norm

Oxygen Parts Cleaning

Industrial Cleaning Solutions

Frequently Asked Questions (FAQ)

What is oxygen parts cleaning?

Oxygen parts cleaning is a specialized industrial process that removes contaminants, oils, greases, and residues from parts that come into contact with pressurized oxygen, ensuring safe and reliable operation.

Why is oxygen parts cleaning critical?

Any contaminants on parts exposed to high-pressure oxygen can pose severe safety risks, including fire or explosion. Proper cleaning reduces these hazards and ensures compliance with safety standards.

Which industries require oxygen parts cleaning?

Industries such as aerospace, medical, chemical, and industrial gas systems rely on cleaning oxygen-contact parts to ensure safety, reliability, and regulatory compliance.

What types of contaminants are removed during the cleaning process?

The process removes oils, greases, metal particles, fibers, dust, and residues from manufacturing or handling, all of which may react dangerously with oxygen under pressure.

How does INVENTEC ensure consistent oxygen parts cleaning?

INVENTEC provides dedicated cleaning solutions, controlled process parameters, validated procedures, and quality monitoring to ensure reproducible and high-performance results.

Are there commercial solutions for oxygen parts cleaning?

Yes. INVENTEC provides specialized cleaning solutions and processes designed specifically for oxygen system components, ensuring safety while protecting the integrity of the parts.

How is cleaned oxygen equipment tested for safety?

Cleaned components undergo rigorous inspections, including Non-Volatile Residue (NVR) analysis and particle counting, as well as functional testing, to confirm compliance with oxygen safety standards before commissioning.

Can oxygen parts cleaning be automated?

Yes. Depending on the part geometry and production volume, automated cleaning systems can be used to improve consistency, reduce handling, and minimize contamination risks.

How often should oxygen parts be cleaned?

The frequency depends on the type of component, operating conditions, and risk assessment, but thorough cleaning is essential during assembly, repair, or maintenance of parts.

Does oxygen parts cleaning affect the longevity of components?

When done correctly, the cleaning process not only ensures safety but also helps maintain the integrity and performance of oxygen-contact components, extending their service life.

Oxygen Parts Cleaning Solutions: Safe cleaning for pressurized oxygen systems

Oxygen parts cleaning solutions are designed to safely remove hydrocarbons,

These solutions employ precision cleaning techniques, including ultrasonic cleaning, solvent rinsing, and specialized drying processes to eliminate residues without damaging sensitive parts. Compliance with environmental and industrial standards is ensured.

Industries such as aerospace and medical devices rely on particle-free and contaminant-free components for safety, performance, and regulatory compliance.

Benefits & Applications

Key BenefitsOxygen Parts Cleaning ensures the complete removal of contaminants such as oil, grease, dust, and other residues from components that will come into contact with pressurized oxygen. This industrial cleaning process minimizes fire hazards, enhances operational safety, and ensures regulatory compliance in aerospace, medical, and other high-reliability sectors.

Technical AspectsOxygen Parts Cleaning uses specialized solvent-based or aqueous cleaning solutions formulated to safely remove hydrocarbons and other residues without damaging sensitive metals and alloys. The process is carefully controlled for temperature, immersion time, and drying methods to guarantee a clean, safe, oxygen-ready surface.

ApplicationsOxygen Parts Cleaning is critical in industries like aerospace & defense and medical for components such as valves, regulators, fittings, and pipelines exposed to high-pressure oxygen. Effective cleaning ensures operational safety, reliability, and compliance with strict safety and environmental standards.

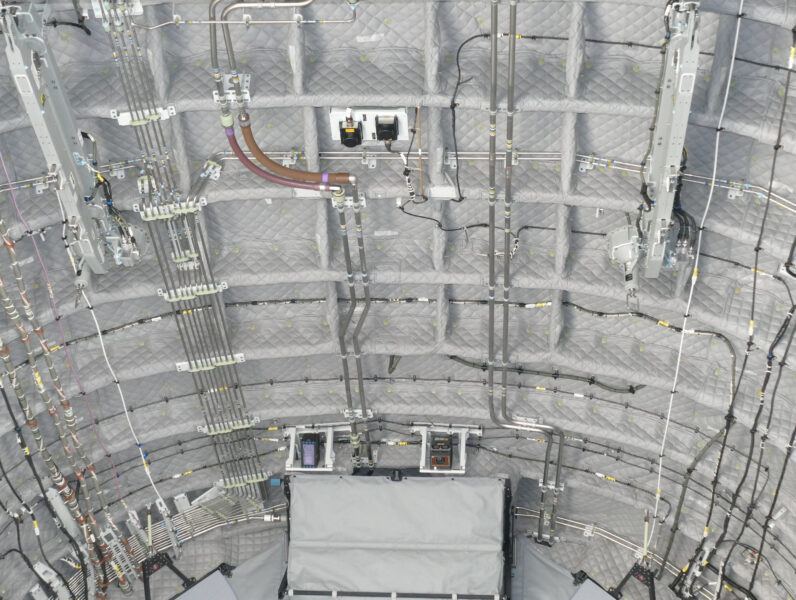

Oxygen Parts Cleaning in Aerospace & Defense

For aerospace components in oxygen systems, proper cleaning removes contaminants to ensure mission safety and long-term reliability under high pressure and extreme conditions.

Oxygen Parts Cleaning in Medical Industry

For medical devices using pressurized oxygen, cleaning solutions prevent contamination and guarantee patient safety. Applications include ventilators, oxygen therapy systems, and delivery components.

Showing all 8 results

-

PROMOSOLV NEO A1

- Light oil & particles removal / rinsing & drying

- Vapor phase, co-solvent, flushing & drying process

- No GWP & PFAS free

- 3M Novec 7100 replacement

-

-

PROMOSOLV NEO B1

- Removal of a wide range of contaminants

- Vapor phase process

- PFAS free & no GWP

- 3M Novec 71DE, Novec 72DE, Novec 73DE, and Novec 8200 replacement

-

PROMOSOLV 70

- Removal of a wide range of contaminants

- Vapor phase process

- Very low GWP: 96

- 3M Novec 71DE, Novec 72DE, Novec 73DE replacement

-

BLUE GOLD

- Degreasing & particle removal from equipment in contact with oxygen

- Aqueous spray & immersion process

- Passes ASTM F-495 and ARP 1775A norm

-

-

-

3M NOVEC 7100

- Light oil & particles removal / rinsing & drying

- Vapor phase, co-solvent, flushing & drying process

- Very low surface tension

Alternative: PROMOSOLV NEO A1

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.