Wave Soldering flux Solutions

Our specialized range of wave soldering flux solutions is engineered for optimal performance in modern wave soldering systems, delivering superior wetting, minimal residue, and reliable soldering results to meet the demands of high-throughput electronic assembly.

High-Performance Wave Soldering Flux Solutions

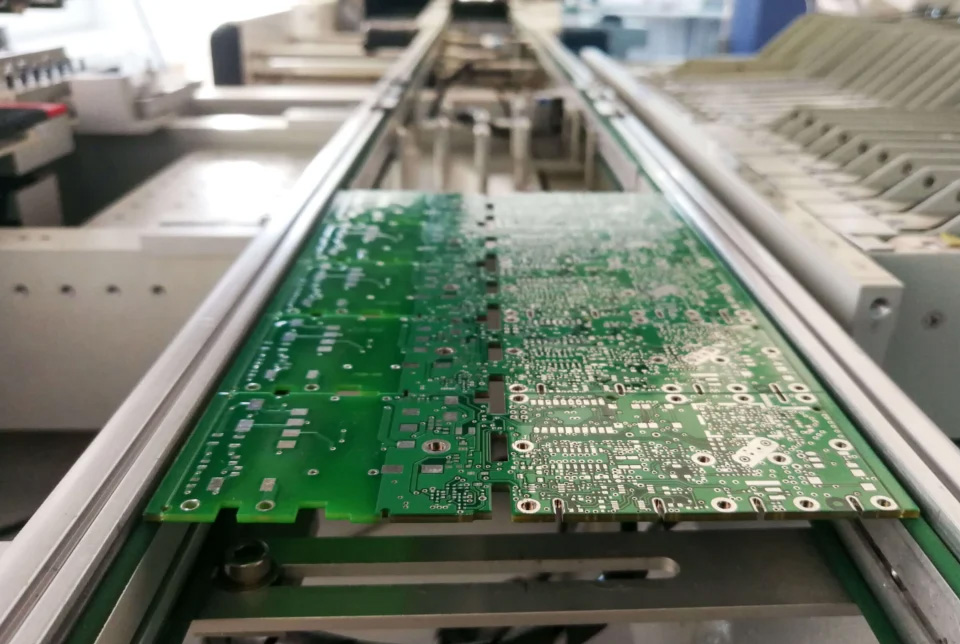

Through-hole technology (THT) components, connectors, switches, and power semiconductors play a crucial role in electronic assemblies, often requiring precise and reliable wave soldering processes. To meet these demands, Inventec offers specialized wave soldering flux solutions designed for consistency, performance, and sustainability.

The advanced ECOFREC™ range of wave flux and wave solder flux products ensures excellent wetting, improved wave solder flow, and the creation of high-reliability solder joints across a wide range of industrial applications. Compatible with both conventional wave soldering equipment and automated production lines, these fluxes support stable process control and leave minimal residue.

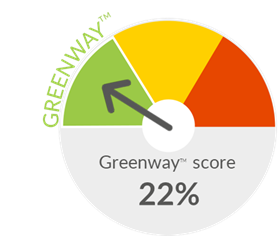

Our portfolio includes both alcohol-based and environmentally responsible, VOC-free, water-based soldering flux formulations. This versatility makes ECOFREC™ wave soldering flux the ideal choice for manufacturers seeking optimized soldering performance with a reduced environmental impact.

Key Benefits of Inventec Wave Soldering Fluxes:

- Superior wetting and flow for reliable solder joints

- Supports both traditional and automated wave soldering processes

- Available in 100% VOC-free water-based or alcohol-based versions

- Designed for high-volume and eco-conscious manufacturing environments

INVENTEC’s ECOFREC™ fluxes ensure high-reliability soldering with excellent wetting, while supporting sustainable manufacturing through VOC-free and residue-minimizing formulations.

See Other Soldering Flux Processes Read FAQ

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Showing all 10 results

-

ECOFREC 205

- Solvent based no-clean liquid flux

- Wave & selective soldering

- Excellent wetting on all board finishes

-

-

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

ECOFREC 303E

- Water-based no-clean liquid flux

- Wave & selective soldering

- Excellent wetting & High electronic reliability

-

ECOFREC 303

- Waterbased VOC free, no-clean liquid flux

- Soldering either with air or nitrogen controlled atmosphere

- High reliability

-

ECOFREC 202

- Solvent based no-clean liquid flux

- Wave & selective soldering

- High reliability and no visual residues

-

ECOFREC DILUENT 1

- Flux thinner for solvent based fluxes.

- Adjust density due to evaporation.

- Made from high purity solvents.

-

ECOFREC DD6

- Solvent based rosin liquid flux

- Wave -, selective spray, foam or manual brush process

- high reliability & easy to clean

-

ECOFREC HT 504

- Solvent based, no-clean rosin liquid flux

- Dipping or manual brush process

- High temperature soldering & easy to clean

-

ECOFREC CMA 155

- Solvent based high rosin liquid flux

- Suitable for all fluxing processes

- Very good wetting & easy to clean

Discover Our Low-Residue No-Clean Flux for Superior Wave & Selective Soldering Performance!

ECOFREC 200

- Solvent based no-clean liquid flux

- Wave & selective soldering

- Excellent wetting & high reliability

Wave Soldering

Soldering Fluxes Solutions

Frequently Asked Questions (FAQ)

What is wave soldering flux?

Wave soldering flux is a chemical formulation applied to the underside of a PCB before it passes through the solder wave. Its purpose is to remove oxides, promote solder wetting, and ensure strong, defect-free joints in through-hole and mixed-technology assemblies.

How does wave soldering flux work?

The flux cleans the metal surfaces, prevents further oxidation during the soldering process, and allows molten solder to flow and adhere properly to component leads and pads. It plays a vital role in the reliability and quality of solder joints.

What types of flux are used in wave soldering?

Common types include rosin-based, water-soluble, and no-clean fluxes. Each offers specific benefits depending on cleaning requirements, residue tolerance, and regulatory constraints. INVENTEC Performance Chemicals offers all three flux types to suit various industrial needs.

When should I choose no-clean flux for wave soldering?

No-clean fluxes are ideal when post-solder cleaning is not feasible or necessary. They leave minimal, non-corrosive residues that are safe to remain on the assembly. These are widely used in consumer electronics and cost-sensitive production environments.

Why use water-soluble flux in wave soldering?

Water-soluble fluxes provide excellent wetting and cleaning power, especially on oxidized or challenging surfaces. They must be cleaned after soldering, making them ideal for high-reliability applications such as medical, aerospace, or military electronics.

What are common defects caused by poor flux performance in wave soldering?

Poor flux performance can lead to defects such as bridging, cold solder joints, non-wetting, and excessive residues. Choosing the right flux and applying it correctly helps eliminate these issues and improves overall soldering reliability.

How is wave soldering flux applied in industrial processes?

Flux is typically applied using foam, spray, or wave fluxers prior to preheating and the solder wave. Uniform coverage and precise control of flux volume are critical for consistent soldering quality and residue management.

How do I choose the right wave soldering flux for my process?

Consider the PCB finish, component type, post-solder cleaning requirements, environmental constraints (RoHS/REACH), and overall process compatibility. INVENTEC offers process-specific flux selection guidance based on your production goals and technical needs.

Are wave soldering fluxes RoHS and REACH compliant?

Yes. Many modern wave soldering fluxes, including those from INVENTEC Performance Chemicals, are formulated to meet RoHS and REACH environmental standards, supporting sustainable electronics manufacturing.

Does INVENTEC offer wave soldering flux solutions?

Yes. INVENTEC Performance Chemicals provides a full range of wave soldering fluxes, including low-residue no-clean, water-soluble, and rosin-based options. These are designed for high-yield performance, low defect rates, and compatibility with various PCB materials and finishes.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

Do you need cleaning or coating after soldering? We provide FREE-OF-CHARGE cleaning or coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. It is also possible to attend trials in person.