High-Reliability SMT Solder Pastes

In applications where long-term reliability and safety are paramount, such as life-critical or harsh-environment electronics, advanced SMT solder pastes ensure dependable performance beyond what conventional solutions can achieve.

High-Reliability SMT Solder Pastes for Demanding Electronic Applications

High-reliability SMT solder pastes are engineered to meet the toughest performance standards in critical electronics. These advanced formulations are essential for systems operating in high-stress environments such as aerospace, automotive safety, industrial controls, and medical technology.

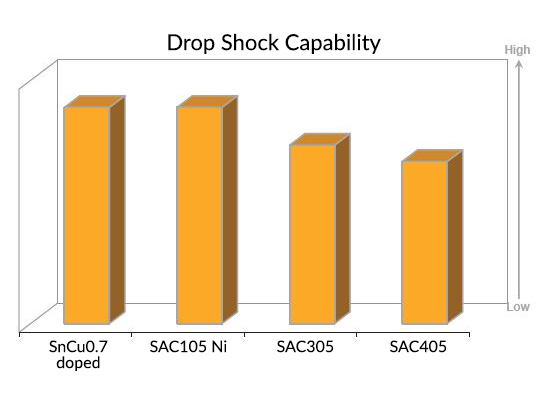

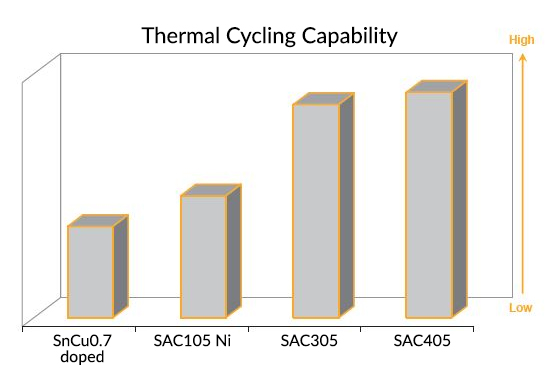

Unlike standard solder pastes, these solutions are designed to withstand thermal cycling, vibration, and mechanical stress over long operational lifespans. INVENTEC’s high-reliability lead-free solder pastes deliver exceptional joint integrity and low voiding, supporting regulatory compliance while maintaining mechanical and thermal resilience.

Featuring proprietary alloy systems, INVENTEC’s high-reliability solder paste portfolio is optimized for both chemical and mechanical endurance. Whether the challenge involves corrosive exposure or constant movement, our products ensure the durability and stability that mission-critical electronics demand.

Key Benefits of High-Reliability SMT Solder Pastes:

- Formulated for extreme environments—thermal, mechanical, and chemical

- Ideal for aerospace, automotive, medical, and safety-critical systems

- Available in lead-free, low-voiding formulations for regulatory compliance

- Engineered for long-term reliability and superior joint strength

INVENTEC provides high-reliability SMT solder paste solutions tailored to meet the toughest performance requirements in advanced electronics manufacturing.

See Other SMT Solder Paste Processes

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Showing all 11 results

-

-

ECOREL FREE 305-21

- SAC305 lead free solder paste

- No clean SMT printing & dispensing process

- High reliability applications

-

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

-

-

-

ECOREL EASY SPA-15

- SnPbAg leaded solder paste

- No clean SMT printing process

- Excellent performance for ultrafine-pitch

-

ECOREL EASY 802M2

- Sn62Pb36Ag2 leaded solder paste in Type 3

- No clean SMT printing process

- Robust assembly

-

-

ECOREL EASY 802M T4

- Sn62Pb36Ag2 leaded solder paste in Type 4

- No clean SMT printing process

- Robust assembly

-

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

Do you need cleaning or coating after soldering? We provide FREE-OF-CHARGE cleaning or coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. It is also possible to attend trials in person.