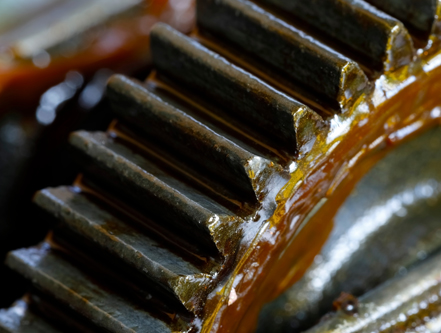

Grease removal from various metal components

Our specialized grease removal solutions are designed for powerful yet safe cleaning of various metal parts, providing thorough grease elimination, reduced processing time, and enhanced surface preparation for downstream treatments.

Effective Grease Removal & Metal Degreasing Solutions

Efficient grease removal is critical for ensuring surface cleanliness and optimal performance of metal components. INVENTEC offers a complete range of metal degreasing solutions designed for high-performance cleaning of all types of grease—including heavy, sticky, or complex formulations.

Whether you’re looking to degrease metal parts manually or via automated cleaning systems, selecting the right metal cleaner and degreaser ensures safe operation, regulatory compliance, and long-term process reliability.

INVENTEC’s advanced cleaning products support your industrial degreasing process while minimizing environmental impact and ensuring safe handling during manual grease removal.

Why Choose INVENTEC?

- High-performance solutions for grease removal on complex metal components

- Environmentally friendly metal degreasing technologies

- Options for both manual and automated cleaning systems

- Compliance with safety, health, and environmental standards

Our Top Grease Removal Products

Explore our recommended grease removal and metal degreasing products for reliable, efficient, and safe cleaning:

| Type of Pollutant | Type of Process | Product Solution |

|---|---|---|

| Grease on Ferrous Metals | Co-Solvent |

|

| Mono-Solvent (Vapor Phase) |

|

|

| Vacuum |

|

|

| Aqueous Spray |

|

|

| Aqueous Immersion |

|

|

| Manual Cleaning |

|

|

| Grease on Sensitive Metals

(Aluminium,…) |

Co-Solvent |

|

| Mono-Solvent (Vapor Phase) |

|

|

| Vacuum |

|

|

| Aqueous Immersion |

|

|

| Manual Cleaning |

|

|

| Perfluorinated Greases | Mono-Solvent (Vapor Phase) |

|

Note: This is a non-exhaustive list. INVENTEC also provides updated legacy products and custom metal cleaner and degreaser solutions tailored to your needs. Use our search tool or contact us for expert guidance.

Optimized Processes for Grease Removal

- Co-solvent: Dual-stage cleaning with Topklean + Hydrofluoroether rinse

- Mono-solvent: Vapor phase degreasing in a single solvent cycle

- Aqueous spray: High-pressure water-based cleaning (in-line, immersion, or spray-in-air)

- Aqueous immersion: Heated tanks, ultrasonic or mechanical agitation for deep cleaning

- Manual cleaning: Spot degreasing using compatible pour, spray, or dip methods

INVENTEC helps you achieve optimal metal degreasing performance with tailored solutions for all grease types and metal substrates. We support both automated and manual grease removal processes with safe, efficient answers to every industrial challenge.

See Other Degreasing Processes Read FAQ

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Showing all 15 results

-

-

3M NOVEC 73DE

- Removal of a wide range of contaminants

- Vapor phase process

- Very low HSE impact & very low surface tension

Alternative: PROMOSOLV NEO B1

-

3M NOVEC 72DE

- Removal of a wide range of contaminants

- Vapor phase process

- High cleaning power & very low GWP

Alternative: PROMOSOLV NEO B1

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

3M NOVEC 71DE

- Removal of a wide range of contaminants

- Vapor phase process

- Medium cleaning power

Alternative: PROMOSOLV NEO B1

-

Discover our Efficient Oil & Grease Removal for Sensitive Alloys!

PROMOCLEAN TP 1113

- Oil & Grease removal

- Aqueous immersion process

- Safe to use on Titanium & Aluminium

This is a product

Grease Removal – Frequently Asked Questions (FAQ)

What is grease removal in industrial cleaning?

Grease removal is the process of eliminating heavy lubricants, oils, and greases from metal and electronic components to prepare surfaces for further processing like soldering, coating, or assembly.

Why is grease removal critical before soldering or coating?

Grease residues can prevent proper adhesion, cause defects such as poor wetting or delamination, and lead to corrosion or electrical failures, impacting product reliability.

What cleaning methods are effective for grease removal?

Common methods include solvent degreasing, aqueous alkaline cleaning, ultrasonic agitation, and vapor degreasing, selected based on grease type and component sensitivity.

Which solvents are recommended for grease removal?

INVENTEC provides advanced degreasing solvents specifically formulated to dissolve tough greases while being safe for sensitive metals and electronics.

Can aqueous cleaners remove grease effectively?

Yes, aqueous alkaline cleaners combined with mechanical action like ultrasonics can effectively break down and remove grease residues in an environmentally friendly way.

How can I verify that grease removal was successful?

Verification can be done via surface cleanliness tests such as wipe sampling, infrared spectroscopy, or contact angle measurements to ensure no residues remain.

Is grease removal compatible with automated cleaning systems?

Absolutely. Automated degreasing and cleaning lines can be optimized for consistent and efficient grease removal, enhancing throughput and quality.

What environmental and safety factors should be considered?

Modern grease removal solutions by INVENTEC emphasize low VOC content, biodegradability, and compliance with environmental regulations for safer, greener processes.

Does grease removal impact subsequent manufacturing steps?

Effective grease removal ensures optimal adhesion, solderability, and coating performance, reducing defects and improving final product reliability.

Does INVENTEC offer grease removal solutions?

Yes, INVENTEC Performance Chemicals provides a range of powerful and environmentally responsible grease removal products tailored to industrial electronics and metal component cleaning.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.