AMTECH™ Solutions

AMTECH solder pastes, solder powders, and process support products, providing a highly complementary addition to the full line of INVENTEC products for the electronic assembly marketplace.

Download Product line card

Select subsegment :

About AMTECH & INVENTEC

INVENTEC acquired AMTECH™ in 2014, from where it received the rights to manufacture and commercialize the AMTECH™ product range.

INVENTEC will remain supplying AMTECH™ products to our worldwide customers but aligned according our INVENTEC branding policy. If you are in doubt that you are buying genuine AMTECH™ product, you can contact us to check if your supply source is an authorized distributor or re-seller. AMTECH™ products are mainly produced in the USA.

INVENTEC Online Shop Press Release Read FAQ

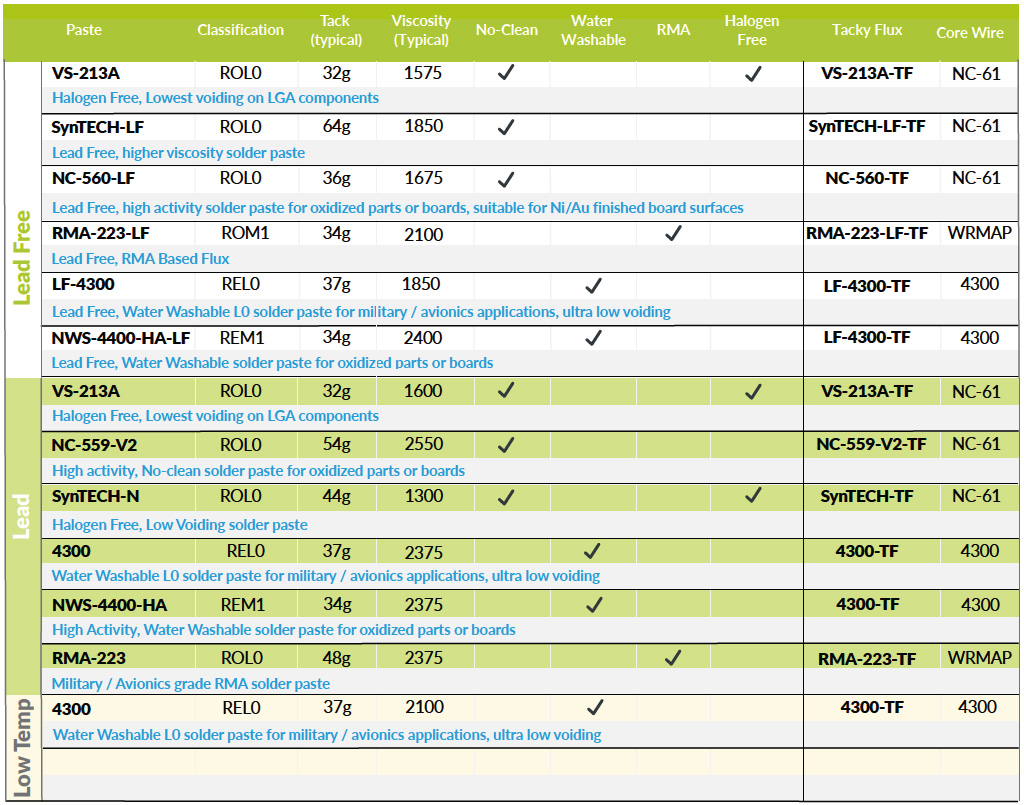

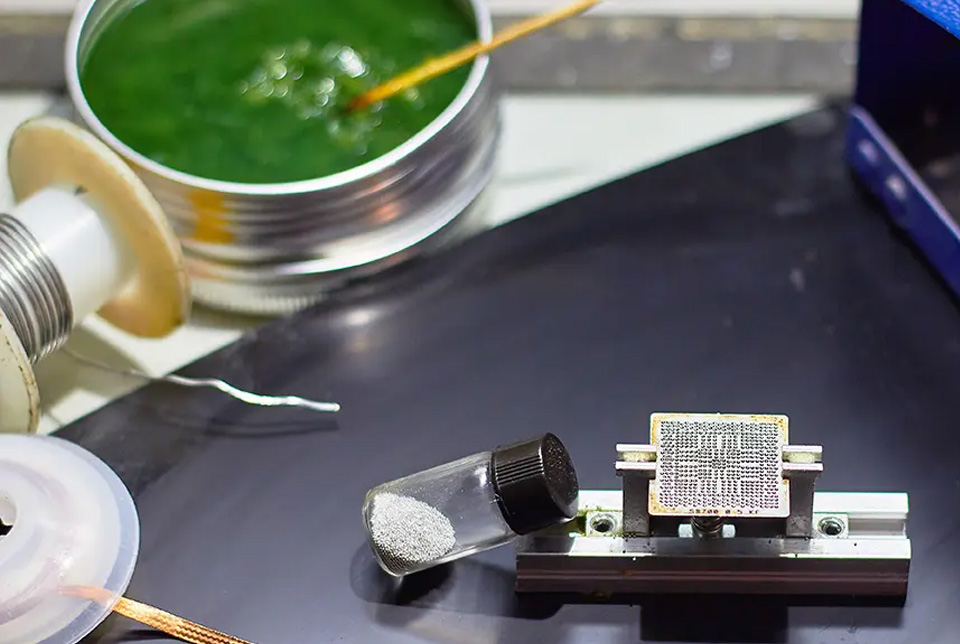

AMTECH Solder Paste

AMTECH offers a wide variety of solder paste, including

no-clean, water washable, and RMA formulations in jars, syringes, cartridges, and ProFlow Cassettes. We offer the industry’s best turnaround time and can ship to meet your most challenging just-in-time (JIT) requirements.

INVENTEC Online Shop Procedures

Trusted by professionals worldwide, AMTECH™ solder paste delivers exceptional printability and consistent, high-quality solder joints. Its advanced formulations minimize defects such as voiding and bridging while ensuring excellent wetting and reliable reflow characteristics.

AMTECH Solder Flux

AMTECH tacky fluxes are designed to complement our entire product line, including no-clean, water washable, and RMA formulations. Our advanced chemistries can be used for general touch-up and rework, attaching spheres to microelectronic packages, and soldering Flip Chip components to various PCB substrates.

Trusted by professionals worldwide, AMTECH™ solder flux delivers excellent cleaning action and optimal solder flow across various applications. Its advanced formula ensures superior wetting, minimal spattering, and reduced residue.

AMTECH Solder Bar

AMTECH bar solderis carefully manufactured using high-purity, conflict-free metals that meet and often exceed stringent IPC industry standards. We offer our bar solder in a wide range of standard alloys and can custom-produce it in non-standard alloys to suit specific application needs.

Trusted by professionals worldwide, AMTECH™ bar solder delivers superior quality and strong, dependable solder joints. Its exceptional purity ensures minimal dross formation, reduced oxidation and improved wetting, making it the ideal choice for soldering processes.

AMTECH Solder Wire

AMTECH core wire is manufactured from high purity “conflict free” metals that meet and exceed all relevant IPC and ASTM B32 standards. Our core wire is available with 1.1, 2.2, & 3.3% flux core in most wire diameters and in many alloys, including lead-free formulations. Our core wire is packaged in easy to use evenly wound rolls.

Trusted by professionals worldwide, AMTECH™ solder wire offers smooth feed, excellent wetting, and reliable joint strength. Its high-purity core flux ensures minimal spatter and residue, making it ideal for precision hand soldering and automated assembly.

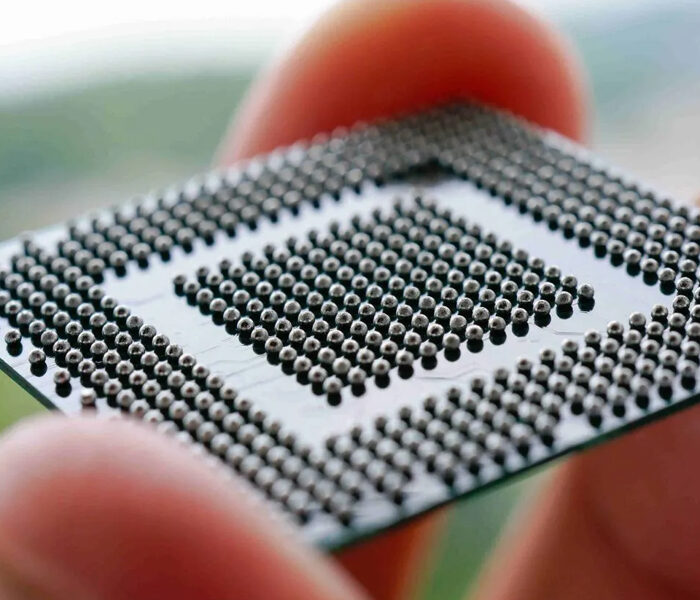

AMTECH Solder Spheres & Preforms

AMTECH manufactures solder spheres and preforms from high purity “conflict free” metals that meet and exceed IPC and MIL standards. Our preforms are custom manufactured to strict tolerances, consistently delivering the desired amount of solder. Our solder spheres are available in all standard sizes and alloys. Custom sizes and alloys are available upon request.

AMTECH™ solder spheres provide uniform size and high purity for dependable solder joint formation. Designed for BGA, CSP, and flip-chip applications, they ensure excellent coalescence, reduced voiding, and consistent reflow characteristics.

AMTECH Solder Powder

AMT, through its subsidiary AMTECH, is the world’s leading producer of electronic-grade solder powders and solder pastes, known for innovation, global reach, and unmatched supply capacity.

Engineered for consistent performance, AMTECH™ solder powder features tight particle size distribution and exceptional purity. It ensures reliable paste performance, excellent wetting, and consistent reflow, making it ideal for high-precision solder paste formulations.

Advanced Metals Technology Inc. (AMT), founded in 1978, is a global leader in the production of electronic-grade solder powders and spheres, known for their low oxide content and precise sizing. The company uses a proprietary separation process to maintain high quality while keeping production costs low. Through its ISO 9001:2008 certified subsidiary, Amtech, Inc., AMT also supplies top-tier solder pastes and fluxes to the electronic assembly market. Within six months of its founding, AMT began full-scale production and quickly became the main supplier to U.S. solder paste manufacturers.

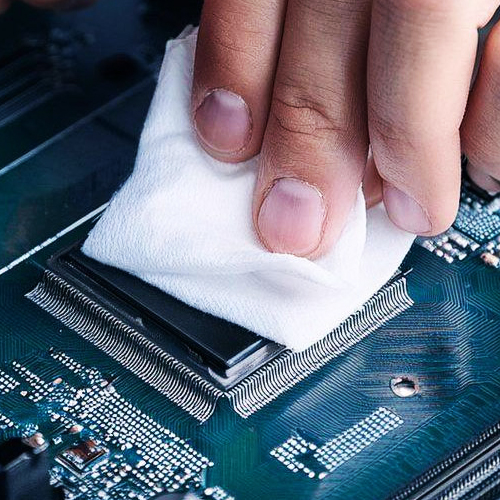

Read moreAMTECH Cleaning Wipes

AMTECH Cleaning Isopropyl Wipes are high-performance, pre-saturated cleaning wipes formulated with a precise blend of high-purity isopropyl alcohol (IPA) and deionized water for fast, effective, and residue-free cleaning. Specifically designed for electronics manufacturing, PCB assembly, and industrial maintenance, these lint-free wipes efficiently remove flux residues, oils, grease, fingerprints, and surface contaminants without damaging sensitive components or plastics.

AMTECH IPA wipes provide consistent, ready-to-use performance in production, rework, and repair environments. Available in convenient packaging formats and standard wipe sizes, they ensure reliable, controlled cleaning for professional electronics applications.

Discover our ultimate no-clean flux solution for flawless soldering!

AMTECH NC-559-V2-TF

- No clean tacky flux

- Leaded soldering

- Excellent wetting properties

AMTECH™ Solutions

Industrial Soldering Solutions

Frequently Asked Questions (FAQ)

When should I use a flux pen?

Dispensing flux into confined areas can be problematic. Use of a flux dispensing pen helps to solve this problem because the flux pen works like a marking pen, dispensing just the right amount of flux where needed. After a certain number of applications, the felt tip starts to wear down, so replacement tips are available. For better dispensing control, consider using a tacky flux instead of an alcohol based flux.

What is the best way to store flammable chemicals?

Generally, flammable chemicals be stored at room temperature with normal humidity, unless otherwise specified. Flammable materials should also be stored in an approved flammable materials storage cabinet. Special care is required when storing flammable chemicals at elevated temperatures, especially alcohol and other chemical compounds that can expand when heated, which could create explosive pressure within the container.How are pin holes formed?

Pin holes are formed by moisture that is trapped within or beneath the solder. When the moisture comes into contact with the component-lead, solder paste, through-hole, wire or material under elevated temperatures, the water can begin to boil, causing pin holes to be formed by trapped or escaping water vapor.

Why is 2% silver sometimes beneficial?

When soldering silver or silver-plated component leads, adding a small amount of silver (typically 2%) to the solder helps prevent the silver found on the component lead from migrating onto the solder, which can result in a weak or brittle solder connection.

What is the ideal size for syringable solder paste?

AMTECH offers 100 grams of paste in a standard 30cc syringe, as well as 35 grams of paste in a standard 10cc syringe. A 30-guage needle is the smallest size recommended for dispensing SMT solder paste (Type 6 powder). Plungers and needles are available upon request.

When is Sn60 recommended over Sn63?

Sn60Pb40 solder paste has a plastic range that allows it to lay down a slightly thicker coating of solder than Sn63Pb37, which is often preferred for lead tinning or similar applications. By contrast, Sn63Pb37 solder is eutectic, with no plastic range, and generally flows better than Sn60Pb40, making it the preferred solder paste solution for surface mount and wave soldering applications.

Do I need to remove rosin flux?

Under normal circumstances, rosin flux residues are non-conductive and non-corrosive and thus do not have to be removed from a printed circuit assembly, except perhaps for aesthetic reasons. However, in situations where the working temperature of the PCB exceeds 200°F, rosin flux residues can melt and become conductive. In such instances, the rosin flux needs to be removed.

How is dross created?

Dross is generated by a combination of heat and agitation that caused oxides to form in various solders. As the solder pot gets hotter, and with increased agitation, the faster the dross gets generated. Dross formation can be reduced or eliminated by the use of nitrogen, which prevents oxygen form reacting with the outer surface of the solder. Dross reducing agents can also be used to minimize tin and lead oxides by releasing oxygen into the air. When using dross-reducing gents, be careful to follow the instructions on the product data sheet and SDS, where applicable.

Can I solder to aluminum?

AMTECH dose not offer any solder products that can be used for soldering to aluminum.

Why are thermocouple wire materials not solderable?

A thermocouple works by measuring the change in resistance of two dissimilar metals joined in a welded bead. If you were to join the two metals with solder, the thermocouple would provide meaningless numbers. In some cases it is possible to surround or encapsulate a thermocouple wire without forming a metallurgical bond. To fix a broken thermocouple, you can attempt to re-weld the thermocouple bead. When attaching a thermocouple to a PCB for reflow profiling, you generally have two choices: utilizing a high temperature alloy to encapsulate the thermocouple; or using a cyan-acrylate adhesive product to attach the thermocouple to the PCB.

How do you properly dispose of processing chemicals?

Chemical disposal regulations vary form state to state and from country to country. We suggest that you contact your local EPA office to verify that proper disposal requirements are being followed. An EPA representative can also recommend qualified hazardous waste handlers in your area. Prepare in advance by having copies of all relevant product data sheets and Safety Data Sheets (SDS) available for review by a certified hazardous waste disposal expert.

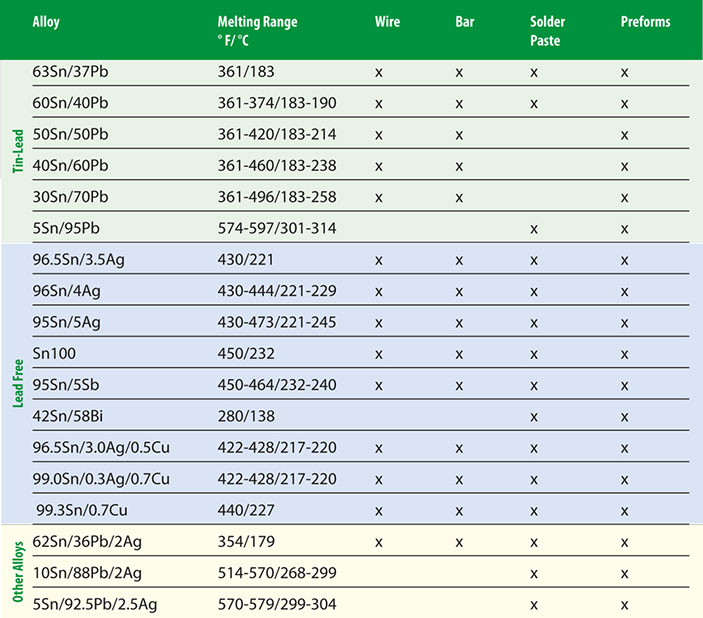

What are the normal temperature ranges of the alloys available for AMTECH?

Gold color is appearing on the surface of the solder pot?

When molten solder is exposed to air it can oxidize and create dross, which can appear as gold or a purple-blue in color. Formation of tin oxide is normal and generally does not degrade the reliability of the solder. This discoloration can be prevented by the use of a dross inhibitor, which is generally available as an anti-oxidant powder or pellet.

What is the standard ratio of flux to metal in a solder paste?

The typical solder paste formula consists of 90% metal and 10% flux by weight, and 45% metal and 55% flux by volume.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

Do you need cleaning or coating after soldering? We provide FREE-OF-CHARGE cleaning or coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. It is also possible to attend trials in person.