Tacky Flux – High-viscosity flux solutions for precise rework

Engineered for stability and strong wetting, our tacky flux products offer excellent solder joint integrity and placement hold during SMT rework and component attachment in manual and automated processes.

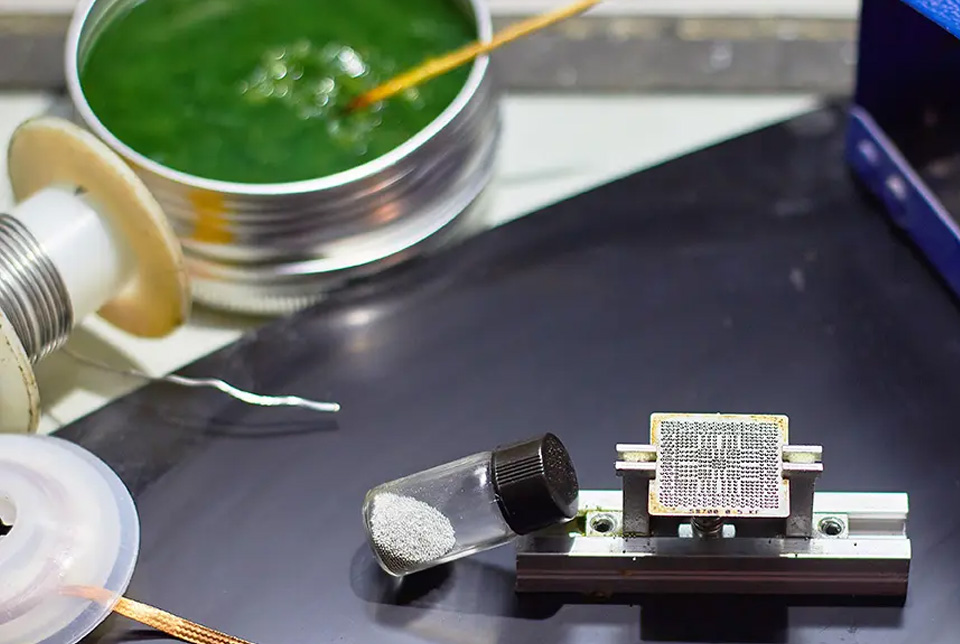

High-Performance Tacky Flux for BGA, QFP & Precision Assembly

In high-reliability electronics manufacturing and repair, tacky flux plays a vital role in achieving clean, repeatable solder joints. Whether you’re engaged in BGA reballing, BGA repair, or delicate QFP rework, Inventec’s ECOFREC™ tacky solder flux solutions provide the precision, control, and consistency your process demands.

Designed for critical applications like BGA assembly and Package-on-Package (PoP) reflow, ECOFREC™ tacky flux delivers optimized rheology, excellent thermal stability, and high activity with minimal residue. These characteristics make it ideal for both manual and automated workflows using dispensing systems, squeegees, or doctor blades.

Trusted in conjunction with leading brands such as Amtech, ECOFREC™ tacky flux ensures strong solder joints, improved wetting, and fewer defects. From high-density PCBA work to fine-pitch component placement, these fluxes are engineered for performance, reliability, and efficiency across all electronics rework and assembly environments.

Key Benefits of Inventec Tacky Flux Solutions:

- Exceptional wetting for BGA, QFP, and PoP processes

- Optimized rheology and thermal stability for precise control

- Minimal residue for cleaner and more reliable solder joints

- Compatible with both manual and automated dispensing systems

INVENTEC’s ECOFREC™ tacky fluxes deliver precision, high thermal stability, and clean solder joints for rework and high-density assembly environments.

See Other Soldering Flux Processes Read FAQ

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Showing all 15 results

-

-

-

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

-

-

-

-

-

-

-

-

AMTECH RMA-223-LF-TF

- Rosin mildly active tacky flux

- Lead-Free soldering

- Excellent wetting properties

-

-

-

ECOFREC TF48

- No clean tacky flux

- Flip Chip, spheres soldering & components rework

- Excellent printing & high viscosity

-

-

Discover Our Halogen-Free No-Clean Tacky Flux for All Your Soldering Needs!

ECOFREC TF49

- Halogen free tacky flux

- Flip Chip & Rework soldering

- Low residue properties

Tacky Flux

Soldering Fluxes Solutions

Frequently Asked Questions (FAQ)

What is tacky flux?

Tacky flux is a semi-solid flux formulation used in PCB assembly and rework processes. Its sticky consistency allows components or spheres (in BGA/CSP assembly) to stay in place before soldering, making it ideal for precision placement and reflow.

What are the main applications of tacky flux?

Tacky flux is commonly used in BGA reballing, PoP (Package-on-Package) assembly, SMT rework, and during solder paste enhancement. It supports accurate component alignment and improves solder joint reliability, especially in high-density assemblies.

What are the benefits of using tacky flux in electronics manufacturing?

Benefits include excellent component adhesion before reflow, enhanced solder wetting, reduced voiding, and improved yield in rework or repair operations. INVENTEC’s tacky fluxes are engineered for high activity and minimal residue post-reflow.

Is tacky flux suitable for lead-free soldering?

Yes. Many tacky flux formulations are optimized for lead-free alloys like SAC305 or SnAgCu systems. INVENTEC offers RoHS-compliant tacky fluxes that support both tin-lead and lead-free reflow with excellent thermal stability.

How is tacky flux applied?

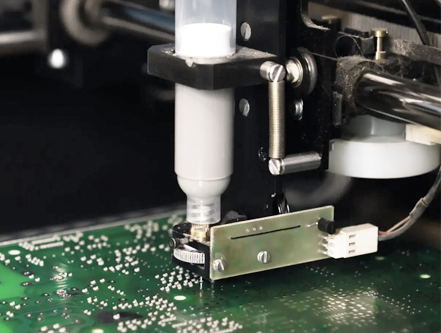

Tacky flux is typically dispensed via syringe, stencil printing, or dipping processes depending on the application (e.g., BGA reballing or SMT rework). Controlled application ensures precise flux coverage and reduces cleaning requirements.

Does tacky flux require cleaning after soldering?

It depends on the type. No-clean tacky fluxes leave minimal, non-corrosive residue and are often left in place. Water-soluble and rosin-based types require post-solder cleaning. INVENTEC provides both cleanable and no-clean versions based on your process needs.

Can tacky flux improve solder paste performance?

Yes. Tacky flux is often used to rehydrate or enhance the wetting behavior of solder paste in rework or secondary reflow. It can reduce defects like head-in-pillow or non-wet opens, especially in BGA and QFN assemblies.

Is tacky flux compatible with automated dispensing?

Absolutely. INVENTEC’s tacky fluxes are designed for consistent rheology, making them suitable for automated syringe or jet dispensing systems used in high-precision electronics manufacturing.

What factors should be considered when selecting a tacky flux?

Consider alloy compatibility, residue behavior, cleaning needs, reflow profile, and application method. INVENTEC offers technical guidance to help you choose the optimal tacky flux for rework, PoP, or high-density soldering applications.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

Do you need cleaning or coating after soldering? We provide FREE-OF-CHARGE cleaning or coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. It is also possible to attend trials in person.