Low Voiding Solder Paste Solutions

Our specialized range of low voiding solder paste solutions is designed to reduce voids in solder joints and enhance thermal and electrical reliability, ideal for high-reliability applications such as automotive, power electronics, and LED assemblies.

Avoid the Void and Maximize Reliability with Low Voiding Solder Pastes

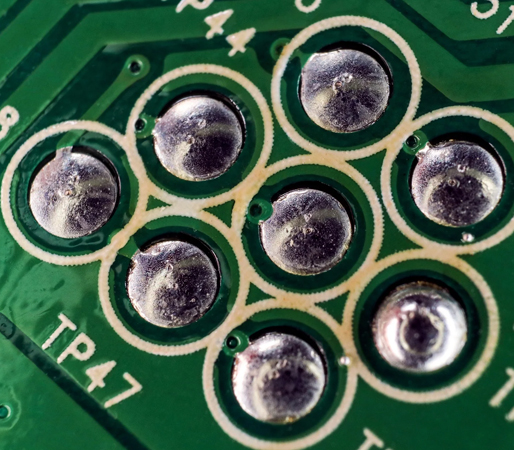

Voids in solder joints pose serious challenges in high-reliability electronics such as automotive, aerospace, LED, and power systems. These voids reduce thermal and electrical conductivity and can severely compromise long-term performance and mechanical strength.

INVENTEC’s low voiding solder paste solutions are specifically formulated to minimize flux outgassing and prevent the formation of voids during reflow. These pastes are critical in assemblies using BTCs, DPAK, BGA, and QFN packages—where void-free solder joints directly contribute to better heat transfer, signal reliability, and durability.

Whether you’re aiming to eliminate a BGA void or improve the structural integrity of thermal pad solder joints, our low voiding pastes help manufacturers achieve greater process control, higher performance, and improved product lifespan.

Key Benefits of Low Voiding Solder Paste Solutions:

- Reduces void formation caused by flux outgassing during reflow

- Enhances thermal dissipation in power components

- Improves mechanical reliability in harsh environments

- Ideal for BGA, QFN, DPAK, and BTC package soldering

- Supports IPC-compliant voiding levels for mission-critical electronics

With INVENTEC’s low voiding solder pastes, you can ensure reliable, high-performance solder joints while meeting the most demanding thermal and electrical requirements.

See Other SMT Solder Paste Processes Read FAQ

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Showing all 5 results

-

ECOREL FREE LT 140-18

- Sn42Bi57.6Ag0.4 lead free solder paste

- Low temperature SMT printing process

- Halogen free & low voiding

-

-

ECOREL HT 301T

- Pb93,5Sn5Ag1,5 Leaded solder paste

- No clean printing process

- Low voids & high reliability

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

-

Discover our low voiding lead free solder paste!

ECOREL 305-16LVD

- SAC305 lead free solder paste

- No clean SMT printing & dispensing process

- Excellent low voiding

This is a product

Low Voiding

Solder Paste Solutions

Frequently Asked Questions (FAQ)

What is low voiding solder paste?

Low voiding solder paste is a specially engineered formulation designed to minimize the formation of voids within solder joints during the reflow process. It ensures better thermal and electrical conductivity, especially for bottom-terminated components (BTCs) such as QFNs, LEDs, and power devices.

Why are voids in solder joints a problem?

Voids can trap gases and reduce the contact area between the component and PCB pad, which lowers thermal and electrical transfer efficiency. In critical applications, excessive voiding may lead to overheating, reduced reliability, or even complete failure of the electronic assembly.

How does low voiding solder paste help reduce voids?

Low voiding solder pastes feature optimized flux chemistries and alloy systems that promote better outgassing and improved wetting during reflow. This combination minimizes trapped volatiles and helps form denser, more uniform solder joints.

What factors contribute to void formation?

Voids can result from excessive flux residue, improper reflow profiles, stencil design, oxidation on pads, and trapped moisture. Using a quality low voiding solder paste along with process optimization significantly reduces these risks.

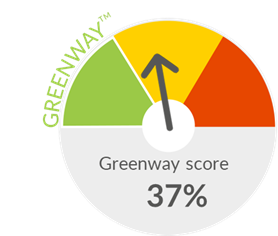

What is an acceptable void percentage in industrial soldering?

Industry guidelines, such as IPC-A-610, recommend less than 25% voiding for BTCs. However, many manufacturers aim for less than 10%, especially in automotive, aerospace, and high-power electronics. Low voiding solder paste helps consistently achieve these benchmarks.

Does the reflow profile affect voiding levels?

Yes. A well-optimized reflow profile with controlled preheat, soak, and ramp-up stages allows for complete flux volatilization and gas escape, reducing void formation. Low voiding solder pastes are formulated to work within such optimized profiles for best results.

Can low voiding solder pastes be used with lead-free alloys?

Absolutely. Low voiding solder pastes are available in lead-free formulations such as SAC305 and other SnAgCu-based alloys. INVENTEC Performance Chemicals offers several RoHS-compliant solutions specifically designed to reduce voiding without sacrificing performance.

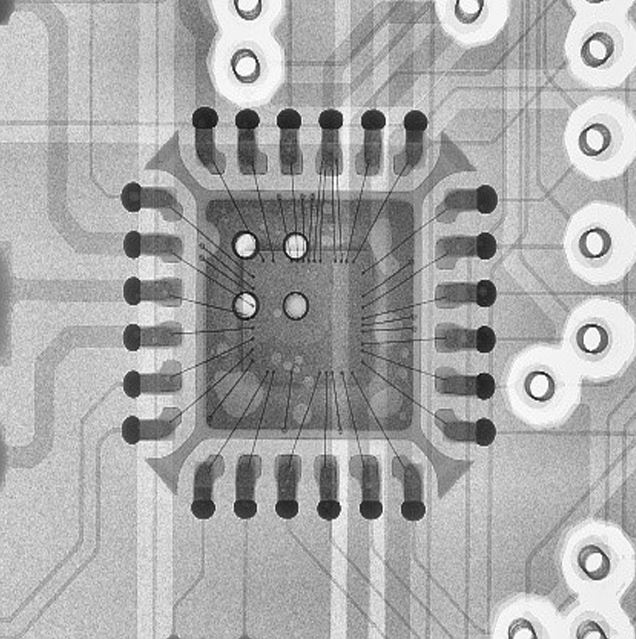

How are voids measured in solder joints?

X-ray inspection is the industry standard for detecting and quantifying voids in solder joints. It provides a non-destructive, high-resolution method to evaluate solder joint integrity and verify compliance with quality standards.

Which components are most sensitive to voiding?

BTCs like QFNs, LEDs, MOSFETs, and power transistors are especially sensitive to voiding due to their reliance on efficient thermal dissipation. Using a low voiding solder paste is critical to maintain performance and reliability in these applications.

Does INVENTEC offer low voiding solder paste solutions?

Yes. INVENTEC Performance Chemicals provides a range of advanced low voiding solder pastes tailored for SMT applications across demanding industries. Their products are tested to meet strict voiding specifications while ensuring excellent printability and wetting.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

Do you need cleaning or coating after soldering? We provide FREE-OF-CHARGE cleaning or coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. It is also possible to attend trials in person.