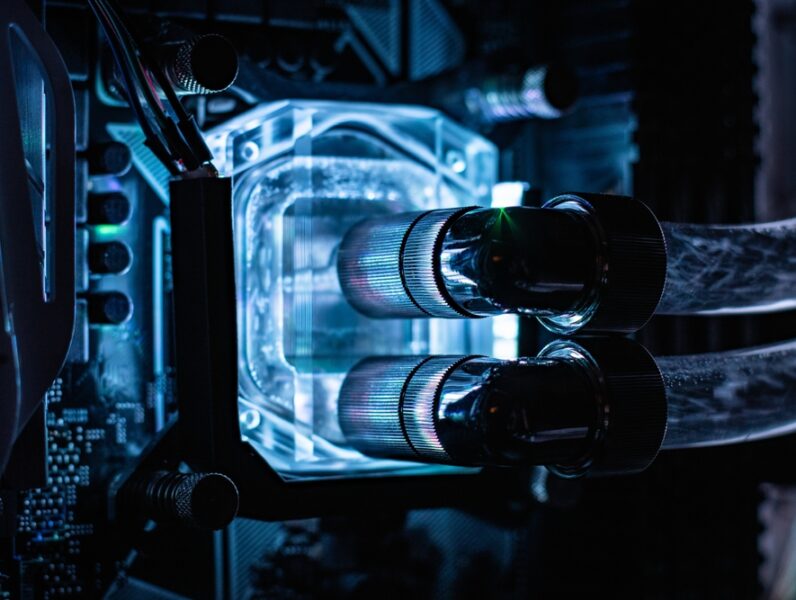

Direct Cooling

Applied directly to the heat source, providing a more effective and controlled temperature regulation.

Meeting the Direct Cooling Challenge with Precision and Performance

With Thermasolv dielectric fluids, INVENTEC offers a high-performance direct cooling solution that enhances energy efficiency, ensures component safety, and meets the demanding thermal needs of advanced electronic and electrical systems.

Showing all 11 results

-

-

-

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

-

-

-

-

-

-

-

Dielectric direct cooling fluids

What are direct liquid cooling fluids?

Direct liquid cooling fluids are used in cold plate and cold tube systems to efficiently remove heat from electronic components. In a cold plate system, the fluid flows through a flat plate attached to the component, transferring heat directly from the component to the liquid. In a cold tube system, the fluid circulates through tubes surrounding the components, absorbing heat as it passes.

Difference between single-phase and two-phase immersion cooling

Single-phase immersion cooling involves immersing electronic components in a dielectric liquid that remains in a single phase (liquid) throughout the cooling process. The liquid absorbs heat from the components, and the temperature of the liquid rises. The heated liquid is then circulated or pumped to a heat exchanger where the heat is transferred away, keeping the components cool. This method is typically simpler and more cost-effective but may not be as efficient in handling higher heat loads.

Two-phase immersion cooling, on the other hand, uses a dielectric liquid that undergoes a phase change from liquid to vapor as it absorbs heat. The heat causes the liquid to evaporate, and the vapor rises to a condenser, where it cools and condenses back into liquid form. This phase change allows for more efficient heat absorption and heat transfer, making it better suited for high-performance computing or systems with higher heat dissipation needs. It’s more complex but offers greater cooling capacity and efficiency.

What are dielectric fluids?

Dielectric fluids are already around for some time in electrical engineering, serving as insulating oils in high-voltage equipment. Dielectric fluids prevent electrical discharges, enhance insulation, and dissipate heat, ensuring the reliability of power systems. Dielectric fluids also find use in cooling electronic components and industrial processes, requiring high-temperature stability. In recent years, dielectric fluids are increasingly considered for immersion cooling of servers in datacenters as an alternative to air cooling. In essence, dielectric fluids play a vital role in ensuring the efficiency and safety of diverse technologies.

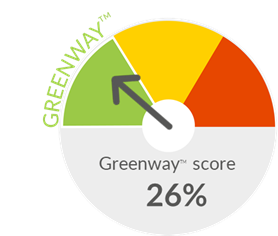

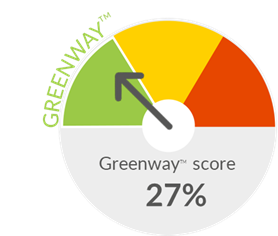

Why choosing THERMASOLV™ dielectric fluids?

DOWNLOAD

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Read more

Showing all 11 results

Discover our dielectric cooling fluids for electronic & electric devices!

THERMASOLV IM7

- Dielectric heat transfer fluid

- Boiling point: 76°C/169°F

- Very low GWP

This is a product

Industrial Cooling Solutions – Direct Cooling – Frequently Asked Questions (FAQ)

What is Direct Cooling in industrial applications?

Direct Cooling involves applying a cooling medium directly to the heat source, enabling faster heat dissipation and more precise temperature control of components.

Why is Direct Cooling important for industrial equipment?

Direct Cooling reduces thermal stress on high-performance machinery, improves energy efficiency, and extends the lifespan of critical components.

How does INVENTEC support Direct Cooling solutions?

INVENTEC develops high-performance dielectric cooling fluids specifically designed for Direct Cooling, ensuring safe operation and effective heat removal from sensitive equipment.

Which types of equipment benefit most from Direct Cooling?

High-density electronics, precision machinery, and high-power industrial systems benefit most from the efficiency and stability provided by Direct Cooling.

What are the main advantages of Direct Cooling over traditional methods?

Advantages include faster heat transfer, lower operating temperatures, more uniform cooling, and reduced energy consumption compared to indirect cooling solutions.

Is Direct Cooling safe for sensitive components?

Yes, when combined with dielectric fluids like those from INVENTEC, Direct Cooling is safe, non-conductive, and protects components while ensuring thermal stability.

Can existing industrial systems be retrofitted for Direct Cooling?

Yes, many systems can be adapted to integrate Direct Cooling methods, provided that appropriate dielectric fluids and engineering solutions are implemented.

How is the cooling medium applied in Direct Cooling systems?

The dielectric cooling fluid is applied directly onto the heat-generating surfaces or circulated through engineered microchannels to maximize efficiency and safety.

Does Direct Cooling reduce maintenance requirements?

Yes, by lowering operating temperatures and minimizing thermal cycling, Direct Cooling can reduce wear and tear, decreasing maintenance frequency and costs.

Are commercial Direct Cooling solutions available?

Yes. INVENTEC provides specialized dielectric cooling fluids designed for Direct Cooling, ensuring reliable, high-performance temperature regulation in demanding industrial applications.

Direct Cooling Guide: Precision Thermal Management with Dielectric Fluids

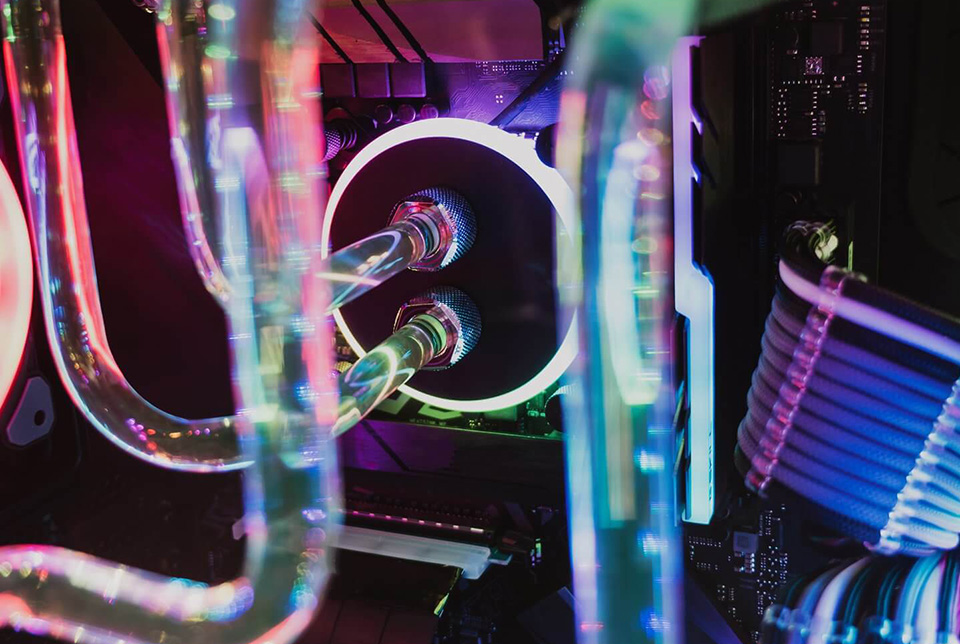

Direct cooling is an advanced thermal management technique where dielectric cooling fluids are brought into direct contact with heat-generating components such as processors, power electronics, or battery cells. Unlike traditional air cooling or indirect liquid systems that rely on heat exchangers, direct cooling removes heat at the source, enabling higher efficiency, compact system design, and superior temperature stability.

This method is increasingly used in sectors where performance density and reliability are critical. By using dielectric direct cooling fluids, manufacturers ensure electrical safety while significantly improving thermal conductivity, reducing energy consumption, and extending component lifetime. Inventec Performance Chemicals offers sustainable direct cooling solutions tailored to industries such as automotive, aerospace, and medical technology, where precision cooling is a decisive factor for innovation and safety.

Benefits & Applications

Key BenefitsDirect cooling applies the cooling fluid directly to the heat source, providing precise temperature control and enhanced thermal efficiency. This method improves system stability, reduces energy consumption, and increases hardware reliability in high-performance computing and critical data applications.

Technical AspectsDirect cooling systems utilize high thermal conductivity fluids and microchannel technology for optimal heat transfer. They are compatible with high-density processors, GPUs, and sensitive electronic components, allowing dynamic thermal regulation and highly effective localized cooling.

ApplicationsDirect cooling is used in high-performance servers, supercomputers, and intensive computing environments. It reduces thermal load, extends component lifespan, and meets the requirements of critical thermal management where air or immersion cooling alone is insufficient.

Direct Cooling for Automotive Power Electronics & EV Batteries

In the automotive industry, direct cooling is becoming essential for managing the heat of electric vehicle (EV) batteries, inverters, and power control units. By applying dielectric fluids directly onto components, manufacturers achieve faster heat dissipation, prevent thermal runaway, and enable ultra-fast charging. This enhances both safety and performance in modern EVs, where traditional air or plate cooling methods are no longer sufficient.

Direct Cooling for Aerospace & Defense Electronics

In aerospace and defense applications, where space and weight are critical, direct cooling ensures reliable performance of avionics, radar systems, and high-density onboard electronics. Dielectric direct cooling fluids offer a safe and lightweight alternative to bulky heat exchangers, allowing equipment to operate efficiently in high-altitude and vibration-intensive environments. This makes direct cooling a strategic choice for next-generation aerospace systems.

Direct Cooling for High-Performance Medical Equipment

Advanced medical devices such as MRI scanners, CT imaging systems, and radiotherapy machines require precise and stable thermal control to ensure diagnostic accuracy and patient safety. Direct cooling with dielectric fluids provides silent, efficient, and compact heat dissipation, reducing downtime while enhancing equipment reliability in demanding clinical environments.

Showing all 11 results

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.