Dielectric Testing

Dielectric cooling fluids and dielectric testing work together to maintain optimal insulation and performance in electronic systems.

Reliable Electronics Start with the Dielectric Testing Challenge

INVENTEC supports dielectric testing with our Thermasolv fluids, providing stable and durable electrical insulation alongside full compatibility with the most stringent and precise testing protocols in modern electronic systems.

Showing all 11 results

-

-

-

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

-

-

-

-

-

-

-

Dielectric cooling fluids and dielectric testing

What is the connection between dielectric cooling fluids and dielectric testing?

Dielectric cooling fluids and dielectric testing are related because both focus on the insulating properties of materials. Dielectric cooling fluids are used in electronic systems to cool components while preventing electrical discharges and enhancing insulation.

Dielectric testing evaluates the ability of materials, including these fluids, to resist electrical breakdown. In industrial applications, dielectric testing ensures that cooling fluids maintain proper insulation and prevent electrical hazards while effectively performing their cooling function.

What are dielectric fluids?

Dielectric fluids are already around for some time in electrical engineering, serving as insulating oils in high-voltage equipment. Dielectric fluids prevent electrical discharges, enhance insulation, and dissipate heat, ensuring the reliability of power systems. Dielectric fluids also find use in cooling electronic components and industrial processes, requiring high-temperature stability. In recent years, dielectric fluids are increasingly considered for immersion cooling of servers in datacenters as an alternative to air cooling. In essence, dielectric fluids play a vital role in ensuring the efficiency and safety of diverse technologies.

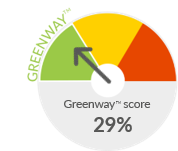

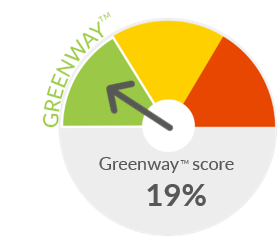

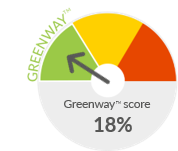

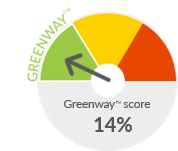

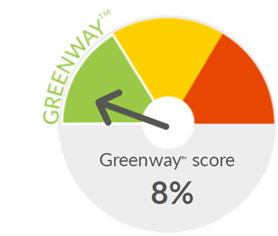

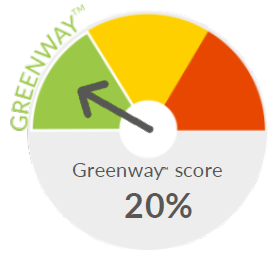

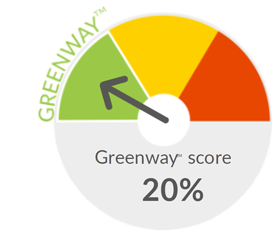

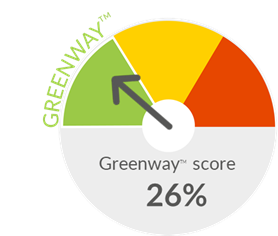

Why choosing THERMASOLV™ dielectric fluids?

DOWNLOAD

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Read more

Showing all 11 results

Discover our dielectric cooling fluids for electronic & electric devices!

THERMASOLV IM7

- Dielectric heat transfer fluid

- Boiling point: 76°C/169°F

- Very low GWP

This is a product

Dielectric Testing

Industrial Cooling Solutions

Frequently Asked Questions (FAQ)

What is dielectric testing?

Dielectric testing measures the insulating properties of a material or fluid to ensure it can safely resist electrical breakdown under operational voltages.

Why is dielectric testing important for cooling fluids?

Cooling fluids in electrical equipment must maintain insulation to prevent short circuits or failures. Dielectric testing ensures fluids meet strict safety and performance standards.

How does INVENTEC support dielectric testing?

INVENTEC provides high-quality dielectric fluids and testing protocols, ensuring that all fluids used in cooling systems meet safety and performance requirements.

What types of equipment require dielectric testing?

Transformers, power electronics, high-voltage servers, immersion-cooled devices, and any equipment where electrical isolation is critical require dielectric testing.

How is dielectric strength measured?

Dielectric strength is typically measured by applying increasing voltage across a fluid sample until breakdown occurs. The voltage at which failure happens indicates the fluid's insulating capability.

Can dielectric fluids degrade over time?

Yes. Contaminants, moisture, and thermal stress can reduce dielectric strength. Regular testing ensures the fluid continues to provide safe insulation.

What makes INVENTEC dielectric fluids suitable for industrial cooling?

INVENTEC fluids are engineered for high dielectric strength, thermal stability, low viscosity, and chemical compatibility, providing reliable and safe cooling solutions.

How often should dielectric fluids be tested?

Testing frequency depends on operational conditions, fluid type, and equipment criticality. Typically, annual or semi-annual testing is recommended for industrial systems.

Can dielectric testing prevent equipment failures?

Yes. By detecting degradation or contamination early, dielectric testing allows timely maintenance or fluid replacement, reducing the risk of electrical failures and downtime.

Does INVENTEC provide testing services or only fluids?

INVENTEC offers both high-quality dielectric fluids and guidance on testing procedures, helping customers maintain safe and efficient cooling systems.

Dielectric Testing Guide for Reliable Cooling & Insulation

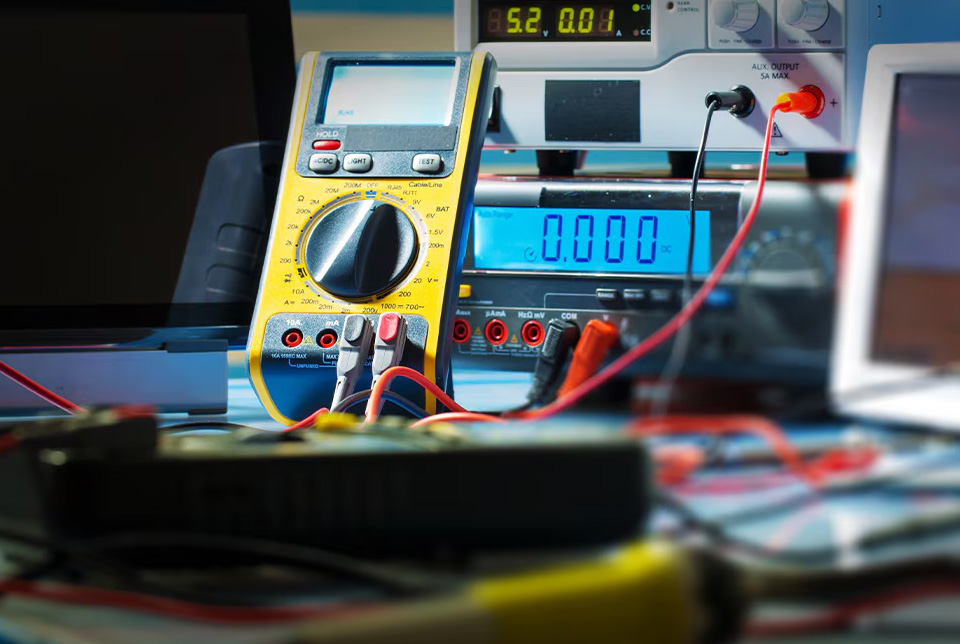

Dielectric testing is a critical process used to evaluate the insulating properties of materials and cooling fluids under high electrical stress. In the context of industrial cooling solutions, it ensures that dielectric cooling fluids can safely operate in environments where heat management and electrical insulation must work together, such as electric vehicles, aerospace electronics, and medical imaging devices.

By measuring parameters such as dielectric strength, breakdown voltage, and resistivity, industries can prevent short circuits, overheating, and equipment failure. For manufacturers and system integrators, dielectric testing is a guarantee of both operational safety and long-term reliability of sensitive electronic components cooled with dielectric fluids.

Benefits & Applications

Key BenefitsDielectric testing ensures optimal insulation integrity in electronic systems. Combined with dielectric cooling fluids, it prevents electrical breakdown, improves system reliability, and extends the lifespan of critical components. These solutions support high-voltage applications while maintaining environmental compliance.

Technical AspectsDielectric testing involves controlled application of voltage to measure insulation resistance and identify potential weaknesses. Dielectric cooling fluids optimize heat dissipation without compromising electrical insulation. These fluids are compatible with high-precision electronics and critical industrial cooling systems.

ApplicationsDielectric testing and dielectric cooling fluids are widely used in data centers, power electronics, semiconductor manufacturing, and high-voltage industrial equipment. They ensure safe operation, improve electrical performance, and help manufacturers comply with strict industry standards.

Dielectric Testing in the Automotive Industry

In electric vehicles (EVs) and hybrid systems, dielectric testing is vital to validate the performance of dielectric cooling fluids used in battery packs, inverters, and power electronics. This ensures reliable thermal management while protecting against electrical breakdown at high voltages.

Dielectric Testing in Aerospace & Defense

For aerospace and defense, dielectric testing guarantees the reliability of avionics systems, satellite electronics, and radar equipment cooled with dielectric fluids. These systems require both efficient cooling and maximum insulation in extreme operating conditions, where equipment failure is not an option.

Dielectric Testing in the Medical Industry

In the medical industry, dielectric testing is essential for equipment such as MRI scanners, X-ray systems, and medical lasers, where cooling fluids must provide safe thermal management without interfering with high-voltage components or patient safety.

Showing all 11 results

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.