Ultra-thin Coatings

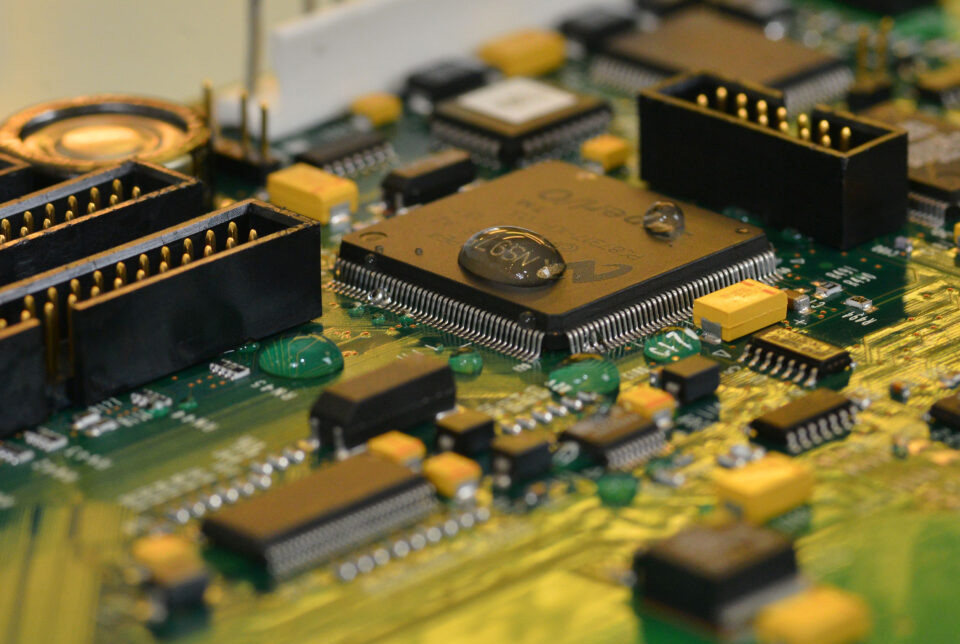

Hydrophobic & oleophobic coatings to protect electronics or other substrate with an easy, fast & environmental friendly process.

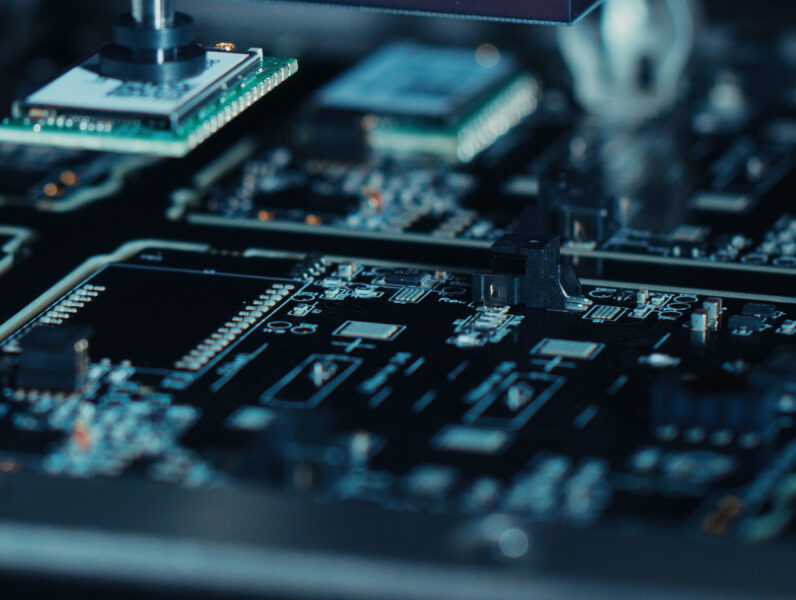

Ultra‑Thin Coatings for High‑Reliability Electronics & Industrial Use

In today’s advanced electronics, automotive, medical, and industrial devices, ultra‑thin coatings (also referred to as nanocoatings) play a critical role. Even at thicknesses as low as 1 µm, these coatings ensure adequate protection against corrosion-causing elements, with no effect on the transmission of light, heat, or radio signals.

These ultra-thin hydrophobic and oleophobic coatings are engineered to repel moisture, solvents, dust, oils, and other contaminants thanks to their extremely low surface energy. Despite being so thin, they provide durable resistance to corrosion, chemical attack, and wear, helping to extend the lifetime of PCBs, sensors, MEMS, connectors, and more.

The low viscosity of the wet coating ensures penetration into micro-crevices, edges, vias and tight geometries, leaving no uncoated “dead zones.” Application can be done via dip coating, spray, or selective spray/deposition systems. Because drying is rapid—often < 1 minute at room temperature—no thermal or UV curing is required in many use cases (e.g. PROMOSOLV COAT UT10).

Key Advantages & Key Features of Ultra‑Thin Coatings

- Fast & easy application: dip or spray + touch‑dry in under 1 minute

- Non‑flammable, free of CMR substances, and very low VOC (environmentally friendly)

- Minimal masking required or even eliminated in many designs

- Space- & weight-saving—no bulk added to sensitive assemblies

- Highly cost‑efficient – only minute amounts used for full protection

- Low investment barrier—suitable for low- to high-volume production

- No adverse impact on RF transparency, LED light emission, or color fidelity

- Excellent adhesion to plastics, glass, metals, ceramics, and standard PCB surfaces

At INVENTEC, our PROMOSOLV COAT UT10 ultra-thin coating is a high-performance, user-friendly solution to protect electronic and industrial surfaces from moisture, corrosion, and chemical stress, while maintaining optical, electrical, and mechanical integrity. For full details, see our product page.

See Other Coatings Solutions Discover our guide Read FAQ

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Showing all 7 results

-

PROMOSOLV COAT UT10

- Ultra-thin hydrophobic & oleophobic coating

- Dipping & spray process

- Easy & fast process

- Available in different dilutions

- 3M Novec 1700 replacement

-

PROMOSOLV COAT UT10-UV

- Ultra-thin hydrophobic & oleophobic coating with UV tracer

- Dipping & spray process

- Easy & fast process

- Available in different dilutions

- 3M Novec 2704 replacement

-

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

-

PROMOSOLV COAT DILUENT 10

- Solvent for dilution of UT10 Coating

- Dipping & spray process

- Non-flammable

-

3M NOVEC 1700

- Ultra-thin hydrophobic & oleophobic coating

- Dipping & spray process

- Easy & fast process

Alternative: PROMOSOLV COAT UT10

-

3M NOVEC 2704

- Ultra-thin hydrophobic & oleophobic coating with UV tracer

- Dipping & spray process

- Easy & fast process

Alternative: PROMOSOLV COAT UT10-UV

Discover our ultra-thin coating for moisture and corrosion protection!

PROMOSOLV COAT UT10

- Ultra-thin hydrophobic & oleophobic coating

- Dipping & spray process

- Easy & fast process

- Available in different dilutions

- 3M Novec 1700 replacement

Ultra-Thin Coatings

Industrial Coatings Solutions

Frequently Asked Questions (FAQ)

What are ultra-thin coatings?

Ultra-thin coatings are extremely fine protective layers, typically below 10 microns, designed to protect sensitive electronic components and assemblies against moisture, corrosion, and contamination without altering their electrical or optical performance.

How do ultra-thin coatings differ from conformal coatings?

While conformal coatings typically have thicknesses between 25 and 250 microns, ultra-thin coatings are much thinner—often below 10 microns—and offer protection at a molecular level. They are ideal for applications requiring full protection without impacting weight, dimensions, or functionality.

Which materials are used in ultra-thin coatings?

Common ultra-thin coatings are based on fluoropolymers, silicones, or hybrid chemistries that provide hydrophobic, oleophobic, and anti-corrosion properties. These formulations ensure excellent adhesion, transparency, and long-term chemical stability.

How are ultra-thin coatings applied?

They can be applied by dipping, spraying, or automated selective coating processes. Their low viscosity and self-leveling behavior allow uniform coverage—even on complex geometries—without the need for masking.

What are the main benefits of ultra-thin coatings?

Ultra-thin coatings provide durable protection against humidity, ionic contamination, and corrosion while maintaining excellent electrical insulation, optical clarity, and thermal stability. They enable faster, more sustainable, and cost-efficient production processes.

Where are ultra-thin coatings used?

They are widely used in automotive electronics (sensors, LiDAR, ECUs), aerospace systems, medical devices, consumer electronics, and optoelectronic components where high reliability and minimal film thickness are required.

Do ultra-thin coatings impact heat dissipation or signal performance?

Properly formulated ultra-thin coatings are engineered to offer excellent dielectric properties and minimal impact on heat dissipation or signal transmission. Their nanoscale thickness ensures thermal and electrical performance remains stable.

How is coating thickness measured and controlled?

Thickness is monitored using advanced inspection techniques such as ellipsometry, X-ray fluorescence (XRF), or microbalance measurements to ensure consistent film quality and repeatability across production batches.

Can ultra-thin coatings be removed or reworked?

Yes, certain types can be removed using mild solvents or micro-abrasion. However, due to their molecular-level bonding, reworkability should be evaluated based on the coating chemistry and component sensitivity.

Are ultra-thin coatings environmentally friendly?

Modern ultra-thin coatings are formulated with low GWP, non-flammable carriers, and minimal waste, making them an environmentally responsible choice compared to traditional protective coatings.

Ultra-Thin Coatings Guide for Advanced Electronic Protection

Ultra-thin coatings are typically below 10 µm and applied to electronic components, sensors, and assemblies to ensure long-term reliability without adding mass or altering functionality. They protect against moisture, corrosion, contaminants, and electrical leakage, while maintaining full electrical and optical performance.

These coatings are based on fluoropolymer or silicone chemistries and are applied through dip, spray, or selective coating methods. Their low viscosity and self-leveling properties allow easy penetration into complex geometries, often eliminating the need for masking and enabling faster, more sustainable production processes.

Benefits & Applications

Key BenefitsUltra-thin coatings offer excellent protection against humidity and ionic contaminants while keeping electrical resistance, optical transparency, and thermal stability. They reduce masking requirements, accelerate throughput, and are compatible with environmentally friendly production lines.

Technical AspectsWith a typical thickness between 100 nm and 10 µm, ultra-thin coatings deliver uniform coverage and strong adhesion to metals, glass, and polymers. They can be hydrophobic, oleophobic, dielectric, or anti-corrosive, and are often non-flammable and VOC-free for safer industrial use.

ApplicationsUltra-thin coatings are ideal for consumer electronics, automotive sensors, aerospace electronics, medical devices, and optical components where high reliability and minimal film thickness are essential.

Ultra-Thin Coatings for Automotive & Mobility Systems

In the automotive industry, ultra-thin coatings protect LiDAR sensors, camera modules, and electronic control units against moisture, road contaminants, and thermal cycling. Their minimal thickness ensures optical precision and reliable long-term operation under extreme conditions.

Ultra-Thin Coatings for Aerospace & Defense Electronics

In aerospace and defense, ultra-thin coatings are applied to avionics, satellite electronics, and navigation modules to resist condensation, pressure variation, and fuel vapors. Their low weight and minimized radio frequency interferences make them ideal for mission-critical components.

Ultra-Thin Coatings for Medical & Diagnostic Devices

Ultra-thin coatings are used on medical sensors, hearing aid devices, medical scanners, and oxygen delivery systems to improve device reliability.

Showing all 7 results

-

PROMOSOLV COAT UT10

- Ultra-thin hydrophobic & oleophobic coating

- Dipping & spray process

- Easy & fast process

- Available in different dilutions

- 3M Novec 1700 replacement

-

PROMOSOLV COAT UT10-UV

- Ultra-thin hydrophobic & oleophobic coating with UV tracer

- Dipping & spray process

- Easy & fast process

- Available in different dilutions

- 3M Novec 2704 replacement

-

-

-

PROMOSOLV COAT DILUENT 10

- Solvent for dilution of UT10 Coating

- Dipping & spray process

- Non-flammable

-

3M NOVEC 1700

- Ultra-thin hydrophobic & oleophobic coating

- Dipping & spray process

- Easy & fast process

Alternative: PROMOSOLV COAT UT10

-

3M NOVEC 2704

- Ultra-thin hydrophobic & oleophobic coating with UV tracer

- Dipping & spray process

- Easy & fast process

Alternative: PROMOSOLV COAT UT10-UV

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning and coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.