Conformal Coatings

Heat- and UV-cured conformal coatings and related thinners from our partner ABchimie™. The latest developments include UV LED-cured coatings that are VOC-free, non-flammable, and significantly speed up your process.

Conformal Coating Solutions for Every Circuit Protection Challenge

Conformal coatings are vital for protecting printed circuit boards in harsh environments by providing a durable, moisture- and chemical-resistant barrier that enhances reliability and extends the lifespan of electronic systems across various industries.

Select subsegment :

ABchimie & Inventec partnership

ABchimie’s sustainable conformal coatings protect PCBs from humidity, corrosion, and temperature extremes to enhance reliability and longevity. Trusted partner INVENTEC ensures global availability of these coatings and other high-quality soldering and cleaning solutions with strong technical support.

ABchimie’s sustainable conformal coatings offer robust protection for PCBs against harsh environmental factors, supported globally through a trusted partnership with INVENTEC…

Read more

Heat cured conformal coatings

Heat cured conformal coatings, such as those from ABchimie, have been around for some time and polymerize, or in other words solidify, through controlled heat curing processes that enhance coating strength, environmental resistance, and long-term reliability for critical electronic assemblies.

Discover the benefits of heat cured conformal coatings for PCBs, offering high-performance protective coating solutions with safer, non-toxic formulations…

Read more

UV cured conformal coatings

ABchimie’s UV-cured coatings, based on advanced UV curing coating technology, offer a significantly faster curing process than heat-cured alternatives, are non-flammable, environmentally friendly, and contain no VOCs, making them an ideal solution to meet strict VOC regulations and avoid related environmental taxes.

Discover how ABchimie’s innovative UV LED-cured conformal coatings provide advanced, energy-efficient protection for PCBs through dual-cure technology and next-generation UV curing solutions…

Read more

Discover Our Flexible, Non-Toxic Conformal Coating for Electronics Protection!

ABCHIMIE AVR80 BA

- Acrylic Conformal coating

- Selective spray, spray gun, dipping & brush process

- Non-toxic & curing at room temperature

Conformal Coating

Industrial Coatings Solutions

Frequently Asked Questions (FAQ)

What are conformal coatings?

Conformal coatings are thin protective layers applied to electronic assemblies to shield them from moisture, dust, chemicals, and temperature fluctuations, improving reliability and lifespan.

Why are conformal coatings important in electronics?

They prevent corrosion, short circuits, and other failures caused by environmental factors, ensuring consistent performance and reducing warranty costs.

Which types of conformal coatings are available?

Common types include acrylic, silicone, polyurethane, epoxy, and parylene, each offering specific protective properties depending on application needs.

How are conformal coatings applied?

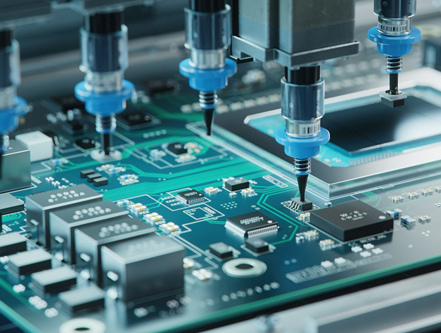

They can be applied using brushing, spraying, dipping, or automated selective coating processes to ensure uniform coverage on sensitive electronics.

How is coating thickness controlled?

Thickness is monitored through controlled application processes and inspection techniques like wet-film measurement, dry-film measurement, or X-ray fluorescence for precise and consistent results.

Do conformal coatings affect thermal performance?

High-quality coatings are designed to provide protection without significantly altering thermal dissipation, though some materials may slightly impact heat transfer and should be selected accordingly.

Can conformal coatings be removed for rework?

Yes, certain coatings can be carefully removed using chemical strippers, mechanical abrasion, or localized heating, allowing for repairs or modifications while preserving component integrity.

Are there industry standards for conformal coatings?

Yes. Standards such as IPC-CC-830 define requirements for coating materials, application methods, inspection, and performance testing to ensure reliability and compliance.

What are common defects in conformal coatings?

Defects can include bubbles, voids, uneven coverage, or contamination. Proper surface preparation, controlled application, and inspection reduce these risks.

Does INVENTEC provide complete conformal coating solutions?

Yes. INVENTEC offers advanced materials, application systems, and process support to ensure reliable, high-quality conformal coating for a wide range of industrial and electronic applications.

Conformal Coatings Guide for Reliable Electronics Protection

Conformal coatings are specialized protective layers applied to printed circuit boards (PCBs) and electronic assemblies to ensure long-term reliability, even in harsh environments. These coatings shield sensitive components from moisture, dust, chemicals, and temperature variations, preventing corrosion, short circuits, and early failures.

Modern industrial conformal coatings include heat-cured and UV-cured coatings, as well as optimized thinners for process flexibility. The latest developments, such as UV LED-cured coatings, are VOC-free, non-flammable, and designed to accelerate production without compromising performance, helping manufacturers meet today’s environmental regulations and reduce operational risks.

Benefits & Applications

Key BenefitsConformal coatings provide essential protection for electronics and circuit boards against moisture, dust, and chemical contaminants. Advanced UV LED-cured conformal coatings are VOC-free, non-flammable, and help accelerate industrial processes while maintaining component reliability.

Technical AspectsConformal coatings deliver excellent adhesion to diverse substrates, uniform thin-film coverage, and are compatible with heat-curing and UV-curing processes. Specialized thinners for conformal coatings ensure optimal viscosity and controlled application in automated or manual processes.

ApplicationsConformal coatings are widely applied in aerospace & defense, medical, and automotive industries to protect sensors, circuit boards, and electronic assemblies. These coatings improve reliability, extend component lifespan, and help manufacturers meet strict environmental and safety regulations.

Conformal Coatings for Automotive Electronics

In the automotive industry, conformal coatings are essential to protect ECUs, sensors, and battery management systems from humidity, vibration, and temperature cycling. With the rise of electric vehicles, UV LED-cured coatings are increasingly adopted to ensure faster, safer, and more sustainable production processes.

Conformal Coatings for Aerospace and Defense Electronics

In aerospace and defense applications, conformal coatings safeguard critical avionics, navigation systems, and communication devices from condensation, fuel vapors, and altitude stress. The high reliability of UV- and heat-cured coatings makes them indispensable for mission-critical environments where failure is not an option.

Conformal Coatings for Medical Devices

In the medical industry, conformal coatings protect sensitive electronics inside diagnostic equipment, implantable devices, and patient monitoring systems. Their ability to resist body fluids, cleaning agents, and sterilization processes ensures device safety and compliance with strict medical standards.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning and coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.