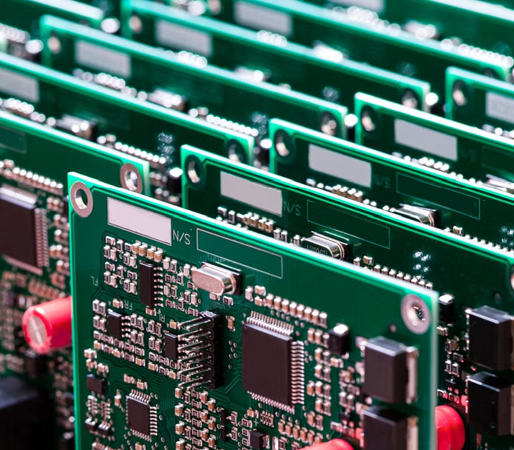

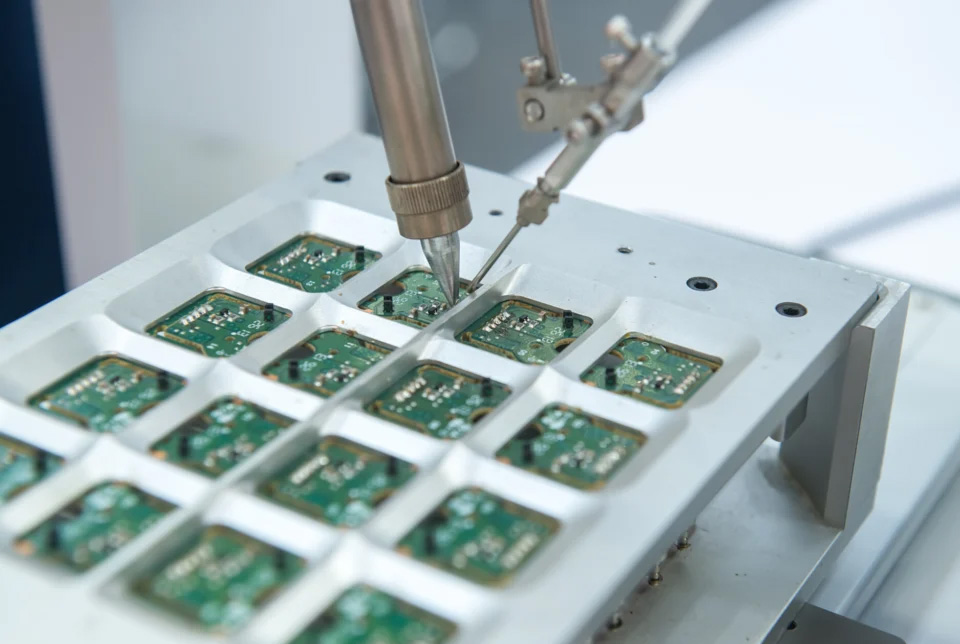

High-Volume PCB Assembly Solder Paste Solutions

Our high-volume PCB assembly solder paste solutions are engineered for optimal performance, delivering precision, reliability, and efficiency to meet the demands of fast-paced, large-scale production environments.

Maximize Efficiency with Robust Solder Paste for High Volume PCB Assembly

In fast-paced electronics manufacturing, high volume PCB assembly demands flawless repeatability, process control, and minimal variation. The performance of your solder paste plays a pivotal role in ensuring consistent yields at scale.

Our high-volume SMT solder paste solutions are specifically engineered to support demanding production lines with a wide range of equipment, stencil designs, and reflow profiles. By offering a broad process window and excellent stability, they minimize defect rates and enhance throughput for complex board layouts.

Whether you’re assembling consumer electronics, automotive modules, or industrial systems, INVENTEC’s robust solder paste formulations help streamline operations and deliver high-quality joints across thousands—or millions—of boards.

Why Choose INVENTEC for High Volume PCB Assembly:

- Wide process window for varying production parameters and equipment types

- Stable, repeatable print performance for reduced variation and fewer defects

- Excellent stencil release for fine-pitch and high-density board designs

- Strong, consistent wetting to ensure joint reliability at scale

- Low residue formulas for easier cleaning and AOI inspection

INVENTEC’s robust solder pastes are engineered to keep your high-volume PCB production lines running efficiently—minimizing downtime while maximizing consistency and reliability.

See Other SMT Solder Paste Processes Read FAQ

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Showing all 3 results

-

-

ECOREL FREE 305-16

- Sac305 lead free alloy solder paste

- No clean smt printing process

- Robust Assembly

-

ECOREL FREE 305-28

- SAC305 lead free solder paste

- No clean SMT printing process

- Robust assembly process

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us

Discover our lead free solder paste for high production volumes!

ECOREL FREE 305-16

- SAC305 lead free alloy solder paste

- No clean smt printing process

- Robust Assembly

High-Volume PCB Assembly

Solder Paste Solutions

Frequently Asked Questions (FAQ)

What are high-volume PCB assembly solder paste solutions?

High-volume PCB assembly solder paste solutions are formulations engineered to deliver consistent performance in fast-paced, high-throughput SMT production environments. They are optimized for long stencil life, stable printability, and minimal defects over extended production runs.

Why is specialized solder paste required for high-volume manufacturing?

High-volume lines demand solder pastes that maintain viscosity stability, reliable print definition, and excellent transfer efficiency over multiple hours and thousands of cycles. These pastes help reduce downtime, rework, and quality variation during continuous production.

What key properties should solder paste have for mass production?

Key properties include long open time, excellent stencil life, anti-slump behavior, consistent tackiness, and high first-pass yield. Solder pastes for high-volume PCB assembly must also exhibit minimal voiding and excellent reflow stability to meet industrial quality standards.

Are these solder pastes compatible with automated SMT lines?

Yes. High-volume solder paste formulations are specifically designed for automated stencil printing, pick-and-place machines, and conveyorized reflow ovens. INVENTEC Performance Chemicals offers pastes optimized for industrial automation and 24/7 SMT line operation.

Which industries benefit from high-volume solder paste solutions?

Industries such as automotive electronics, consumer goods, industrial automation, home appliances, and LED manufacturing benefit from these solutions. These sectors often run large-scale PCB assembly operations requiring repeatable quality and maximum throughput.

How does solder paste stability affect production efficiency?

Stable solder paste maintains its printability and performance characteristics over time, reducing the need for cleaning, reapplying, or adjusting printing parameters. This ensures fewer line stoppages and consistent solder joint quality across high output volumes.

What alloy types are used in high-volume production solder pastes?

Common lead-free alloys include SAC305, SAC0307, and other SnAgCu variants. These alloys offer strong thermal and mechanical performance and are widely accepted in RoHS-compliant manufacturing. INVENTEC provides a full range of compatible alloy formulations for high-volume use.

Can high-volume solder pastes help reduce total cost of ownership?

Yes. Reliable solder pastes reduce rework, material waste, inspection failures, and maintenance downtime. Over time, this significantly lowers the total cost per assembled unit in large-scale PCB manufacturing.

How do I select the right solder paste for high-volume production?

Consider paste stability, reflow characteristics, stencil life, compatibility with your alloy, and the type of components used. Collaborating with a supplier like INVENTEC Performance Chemicals ensures the paste matches your production goals and performance requirements.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

Do you need cleaning or coating after soldering? We provide FREE-OF-CHARGE cleaning or coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. It is also possible to attend trials in person.