SMT Glue Cleaning

Our range of advanced SMT glue cleaning solutions is designed to deliver precision, effectiveness, and reliability, ensuring thorough adhesive removal for flawless electronics cleaning and efficient semiconductor cleaning in today’s high-performance assemblies.

Effective SMT Glue Cleaning Solutions for Electronics & Semiconductor Applications

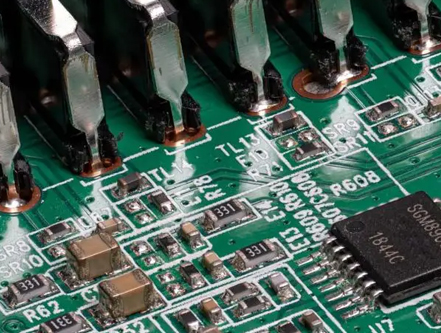

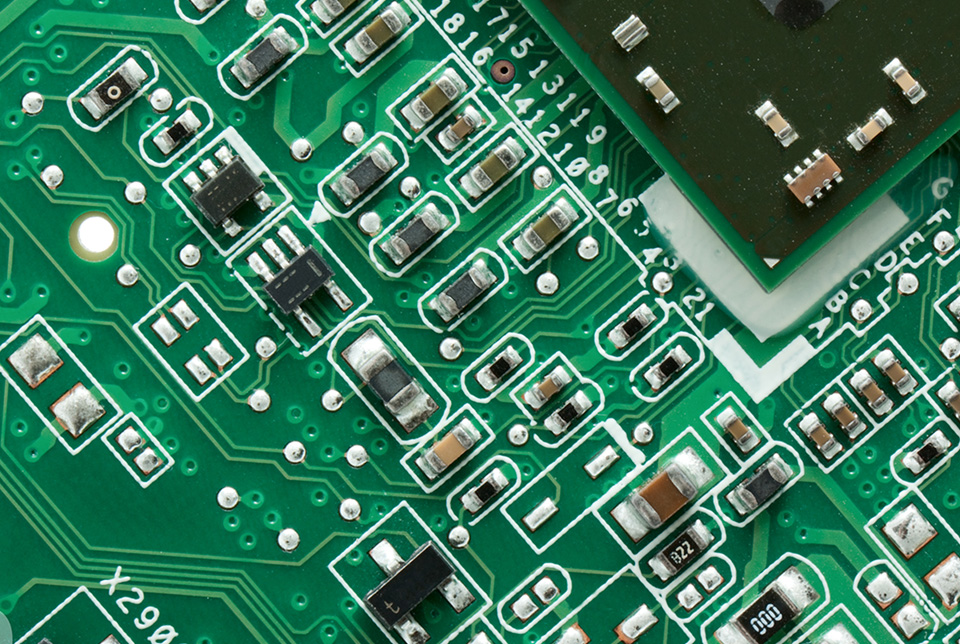

SMT glue (Surface-Mount Technology glue) plays a critical role in securely bonding substrates during electronic and semiconductor device assembly. However, removing cured SMT adhesives can be challenging due to their strong bonding properties, requiring specialized cleaning solutions tailored to your specific adhesive type.

While cured adhesive removal often needs expert guidance and customized products, uncured electronic adhesives are easier to clean. INVENTEC offers proven, safe, and effective products specifically formulated for cleaning glue in both electronics cleaning and semiconductor cleaning processes, ensuring component integrity is maintained.

If you face difficulties removing adhesive residues or need help selecting the right solution, INVENTEC’s expertise and advanced product range provide reliable and efficient options for seamless SMT glue removal and overall electronics cleaning performance.

Key Features of SMT Glue Cleaning Solutions

- Specialized cleaning products for cured and uncured SMT adhesives

- Safe and effective for sensitive electronic and semiconductor components

- Tailored solutions based on adhesive type and application requirements

- Expert guidance for complex adhesive cleaning challenges

INVENTEC delivers specialized SMT glue cleaning solutions designed to optimize electronics and semiconductor cleaning while preserving component performance.

Explore More Cleaning Solutions Read FAQ

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Showing all 4 results

-

-

-

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

QUICKSOLV FIDES

- Oil & dust removal for dielectric cleaning

- For manual spray equipment

- Safe & fast cleaning under power

Discover our Powerful All-in-One Industrial Cleaning Solution!

QUICKSOLV DEF 90

- Multi-purpose cleaner

- Manual cleaning

- Non-flammable

SMT Glue

Electronic & Semiconductor Cleaning Solutions

Frequently Asked Questions (FAQ)

What is SMT glue cleaning?

SMT glue cleaning refers to the process of removing adhesive residues used in surface mount technology (SMT) assembly to ensure clean surfaces and reliable component placement.

Why is cleaning SMT glue important?

Residues from SMT adhesives can interfere with solderability, cause contamination, and affect electrical performance, so thorough cleaning is essential for quality assembly.

What types of adhesives are commonly cleaned in SMT processes?

Common adhesives include epoxy-based glues, acrylic adhesives, and UV-curable adhesives used for component fixation during SMT assembly.

Which cleaning methods are used for SMT glue removal?

Cleaning methods include solvent-based cleaning, ultrasonic agitation, and aqueous cleaning with specialized chemistries designed to break down adhesive residues without damaging components.

Are there specific cleaning agents for SMT glue?

Yes, INVENTEC offers advanced cleaning solutions formulated to effectively remove SMT adhesive residues while being safe for sensitive electronic materials.

Can SMT glue cleaning be integrated into automated processes?

Many SMT glue cleaning steps can be automated in production lines, using spray-in-air or ultrasonic cleaning systems to ensure consistent residue removal.

How does SMT glue cleaning impact product reliability?

Effective removal of adhesive residues prevents contamination-related defects, improves solder joint quality, and enhances overall device reliability.

What environmental considerations apply to SMT glue cleaning?

Cleaning agents must comply with environmental regulations concerning VOCs, biodegradability, and toxicity; INVENTEC’s formulations prioritize eco-friendly performance.

How is the effectiveness of SMT glue cleaning verified?

Verification involves visual inspection, surface contamination analysis, and functional testing to ensure adhesives are fully removed without residue.

Does INVENTEC supply cleaning products for SMT glue removal?

Yes, INVENTEC Performance Chemicals provides specialized cleaning chemistries tailored for effective and safe SMT glue cleaning in electronics manufacturing.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.