Power Electronics Cleaning

Our advanced power electronics cleaning solutions ensure efficient removal of contaminants from heat sinks, circuit boards, and connectors, optimizing thermal management, preventing failures, and enhancing the reliability and longevity of high-performance power electronic systems.

Boost Reliability and Performance with Expert Power Electronics Cleaning Solutions

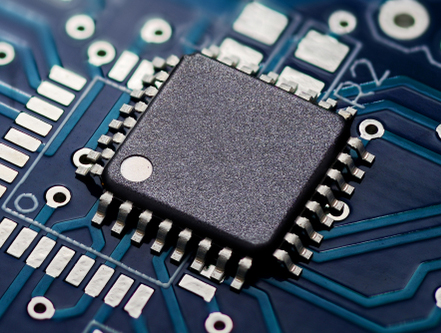

Proper cleaning of power electronics is crucial for maximizing performance, extending lifespan, and ensuring operational reliability in today’s advanced power electronic systems. Over time, components such as circuit boards, connectors, and heat sinks accumulate dust, oil, and other contaminants. Without a consistent cleaning process, this buildup can impair thermal management, leading to overheating, system inefficiency, and even permanent damage.

In high-precision sectors like semiconductor manufacturing, telecommunications, and industrial automation, maintaining clean power electronics is essential. Contaminants on these delicate components can cause short circuits, electrical arcing, and degraded connections. A dedicated electronics cleaning routine not only safeguards functionality but also reduces the frequency of unexpected failures and costly downtime.

INVENTEC offers advanced cleaning solutions such as semiconductor cleaning and DCB cleaning designed to remove flux residues, dust, and oxidation without damaging sensitive surfaces, helping maintain peak performance of your power electronics.

Why Choose INVENTEC for Semiconductor Cleaning and DCB Cleaning?

- Industry-leading solutions tailored for safe and effective semiconductor cleaning and DCB cleaning (Direct Copper Bonded substrates)

- Specialized products that remove flux residues, dust, and oxidation without harming delicate surfaces

- Suitable for a wide range of applications including industrial power converters, solar inverters, electric vehicles, and telecom equipment

- Enhances efficiency, durability, and reliability of your power electronic systems

INVENTEC offers expert power electronics cleaning solutions designed to protect and extend the life of critical power electronic components through advanced semiconductor and DCB cleaning technologies.

Explore More Cleaning Solutions Read FAQ

Read moreDiscover our eco-friendly PFAS-free vapor phase and co-solvent cleaning solution!

PROMOSOLV NEO A1

- Light oil & particles removal / rinsing & drying

- Vapor phase, co-solvent, flushing & drying process

- No GWP & PFAS free

This is a product

Power Electronics

Electronic & Semiconductor Cleaning Solutions

Frequently Asked Questions (FAQ)

What is power electronics cleaning?

Power electronics cleaning involves the removal of flux residues, contaminants, and particulates from power electronic components and assemblies to ensure optimal performance and reliability.

Why is cleaning important for power electronics?

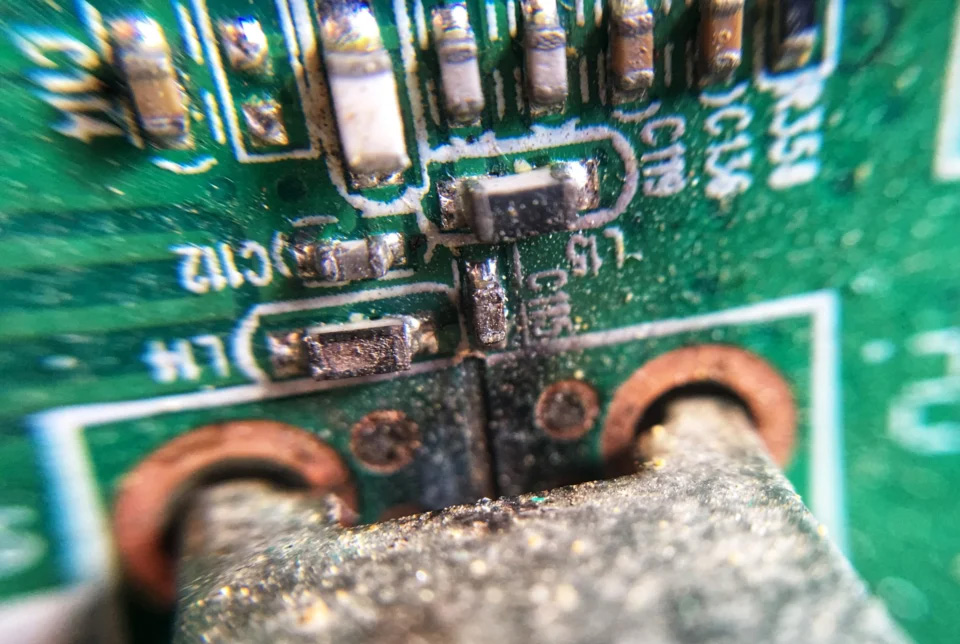

Cleaning is essential to prevent corrosion, electrical shorts, and insulation failures caused by residual fluxes and contaminants, especially given the high voltages and currents in power devices.

What are the challenges in cleaning power electronics?

Power electronics components often have large sizes, complex geometries, and sensitive materials requiring specialized cleaning processes and chemicals to avoid damage while achieving thorough residue removal.

Which cleaning methods are commonly used for power electronics?

Aqueous cleaning, solvent-based cleaning, ultrasonic cleaning, and selective spraying techniques are commonly employed, tailored to the specific component and assembly requirements.

How does cleaning improve reliability in power electronics?

Effective cleaning removes corrosive flux residues and particulates, improving insulation resistance and thermal conductivity, thereby extending device lifespan and reducing failure rates.

Are there specific cleaning chemicals for power electronics?

Yes, INVENTEC Performance Chemicals offers specialized cleaning solutions formulated to safely remove flux residues and contaminants from power electronics without damaging sensitive materials.

Can power electronics cleaning be integrated into automated production lines?

Many cleaning processes for power electronics are designed for automation, including batch and inline systems with controlled process parameters for consistent cleaning quality.

What environmental considerations affect power electronics cleaning?

Cleaning solutions must comply with environmental regulations on VOC emissions, biodegradability, and hazardous substances. INVENTEC emphasizes eco-friendly chemistries to meet these standards.

How is cleaning effectiveness verified in power electronics?

Inspection methods include ionic contamination testing, visual inspections, and electrical testing to ensure thorough removal of residues and contaminants.

Does INVENTEC supply cleaning products for power electronics?

Yes, INVENTEC Performance Chemicals provides a range of cleaning agents specifically designed for power electronics cleaning to support high reliability and manufacturing efficiency.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.