ECOFREC 202

Best in class solvent solder flux

- Solvent based no-clean liquid flux

- Wave & selective soldering

- High reliability and no visual residues

ECOFREC 202

Developed to have a good wettability on different PCB lead free finish as OSP, Ni/Au, Sn, Ag. ECOFREC 202 is a very low dry extract flux which can be used for lead free soldering, by foam or by spray.

Its activation system, without any halide (Fluoride, Chloride or Bromide) and no amine, is eliminated after wave soldering, without leaving any visible residue on printed circuit boards.

FEATURES

| SPECIFICATIONS | ECOFREC 202 |

|---|---|

| Appearance | Colourless liquid |

| Density at 20°C | 0.814 – 0.822 |

| Flash point | 16°C |

| Dry extract, 3 h at 105°C | 1.9 % |

| Halogen content | No halogen |

| Acid index (mg KOH/g of solution) | 19 |

CHARACTERISTICS

| FUNCTIONAL TESTS | Results | Procedures |

|---|---|---|

| Classification | ORL0 | ANSI/J-STD-004 |

| Copper mirror | Pass | ANSI/J-STD-004 |

| Silver chromate paper | Pass | ANSI/J-STD-004 |

| SIR | Passed (see curve below) | IPC TM 650 |

| Bono test | Passed | INVENTEC MO.SB.10029 |

Benefits

PERFORMANCE

- Compatible with a wide range of solder mask

- Compatible with different PCB lead-free finishing as Ni/Au, Sn, Ag, HAL and OSP

- good wetting

- no visual flux residue after soldering

- High SIR values and BONO test compatible

- Possible to use with leaded and lead-free product

COST

- Passes Bono test to guarantee a long life time of your product.

- No flux residue cleaning required

- No interference with electrical test probes

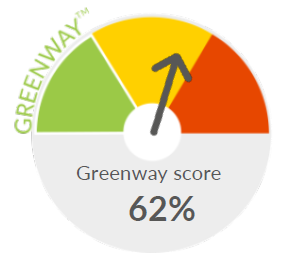

HSE

- No CMR substances

- Free of halogen and amine

Process Recommendation

The best process will depend on factors such as operating conditions, equipment, board or component design. Check our product datasheet for info on process recommendations. In any case, our team is ready to advise and assist you in the implementation of our products.