Misprint & Stencil Cleaning

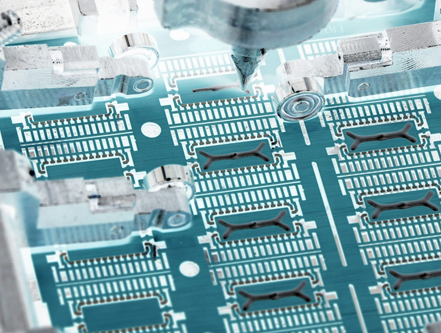

Our full range of advanced misprint & stencil cleaning solutions is designed to deliver precision, efficiency, and reliability, ensuring optimal cleaning performance and high-quality results in SMT printing and electronics manufacturing.

Efficient Misprint & Stencil Cleaning for Reliable SMT & Semiconductor Manufacturing

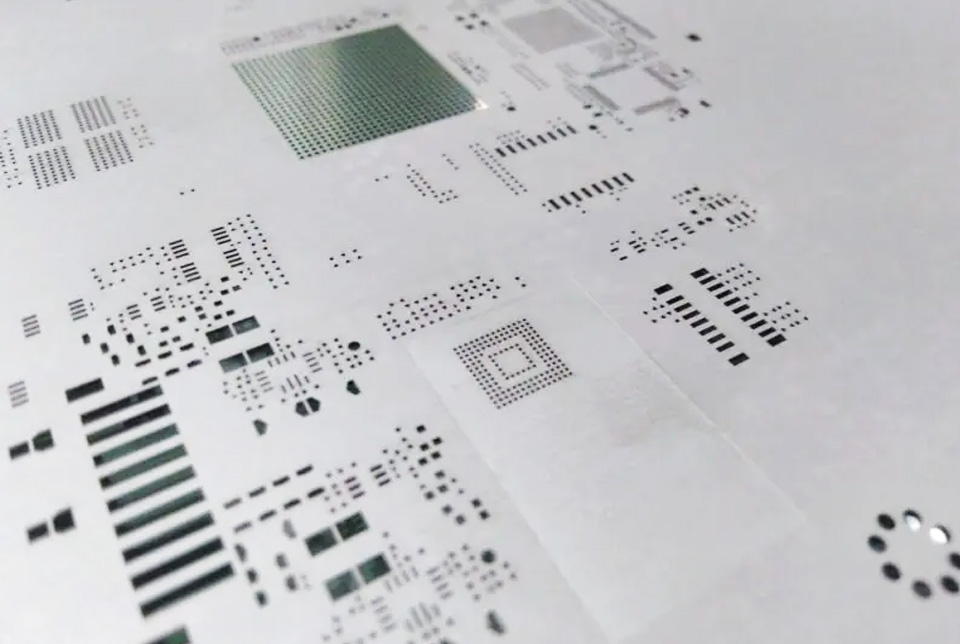

In SMT printing and PCB SMT assembly, effective stencil cleaning is vital to prevent costly misprints and maintain high-quality production. Automated cleaning solutions, like TOPKLEAN EL 7, offer optimized performance with fast cleaning cycles that protect both stencils and cleaning equipment, ensuring consistent workflow efficiency.

Maintaining the integrity of solder paste viscosity during under stencil wipe cleaning is critical to avoid affecting paste performance. INVENTEC’s specialized products are designed to deliver thorough cleaning without compromising paste quality, making them ideal for both high-volume semiconductor cleaning processes and precise electronics cleaning in SMT manufacturing.

By integrating INVENTEC’s advanced misprint and stencil cleaning solutions, manufacturers can reduce downtime, enhance throughput, and ensure reliable, high-quality assembly processes across electronics and semiconductor production lines.

Key Benefits of Misprint & Stencil Cleaning Solutions

- Automated and manual stencil cleaning options for all production volumes

- Specialized chemistry ensuring solder paste viscosity is maintained

- Fast cleaning cycles that reduce water usage and downtime

- TOPKLEAN EL 7 for superior cleaning performance in SMT and PCB stencil printers

INVENTEC provides high-performance misprint and stencil cleaning solutions, including TOPKLEAN EL 7, to ensure reliable and efficient SMT and semiconductor manufacturing processes.

Explore More Cleaning Solutions Read FAQ

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Showing all 4 results

-

-

-

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

Discover our high-performing solder stencil cleaner!

TOPKLEAN EL 606

- Stencil cleaning

- Aqeous spray or immersion process

- Fast cleaning with very low HSE impact

This is a product

Misprint & Stencil

Electronic & Semiconductor Cleaning Solutions

Frequently Asked Questions (FAQ)

What is misprint and stencil cleaning in electronics manufacturing?

Misprint and stencil cleaning refers to the removal of excess or incorrect solder paste deposits (misprints) and the cleaning of stencils used in SMT solder paste printing to maintain process accuracy and quality.

Why is cleaning stencils important in SMT assembly?

Regular cleaning of stencils prevents clogging of apertures, ensures precise solder paste deposition, and reduces defects such as insufficient or excessive solder, improving assembly yield.

What causes misprints in solder paste application?

Misprints are often caused by stencil damage, clogged apertures, misalignment, or improper solder paste viscosity and can lead to solder bridging, open joints, or tombstoning.

Which cleaning methods are used for stencil and misprint cleaning?

Cleaning methods include manual wiping, automated stencil cleaning machines using solvents or aqueous solutions, and ultrasonic cleaning to effectively remove solder paste residues.

Are there specialized cleaning agents for stencil cleaning?

Yes, INVENTEC offers cleaning chemicals specifically formulated to dissolve and remove solder paste residues quickly while preserving stencil integrity and reducing corrosion risks.

How often should stencils be cleaned during production?

Frequency depends on production volume and solder paste type but typically occurs every few print cycles or shifts to maintain consistent paste release and prevent defects.

Can misprint cleaning improve product quality?

Yes, promptly cleaning misprints reduces solder defects, rework, and scrap rates, ensuring higher first-pass yields and reliable solder joints.

Are automated stencil cleaning systems effective?

Automated cleaning systems enhance efficiency, reduce downtime, and ensure consistent cleaning quality, making them ideal for high-volume SMT production lines.

What environmental considerations apply to stencil cleaning?

Cleaning agents should comply with environmental regulations concerning VOCs and waste treatment; INVENTEC emphasizes eco-friendly and biodegradable solutions.

Does INVENTEC provide solutions for misprint and stencil cleaning?

Yes, INVENTEC Performance Chemicals offers a range of cleaning products tailored for efficient misprint removal and stencil cleaning in electronics manufacturing.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.