ECOREL FREE JP32

Jet printing equipment solder paste

- SAC305 solder paste

- Jet printing process

- Easy cleanable flux residues

ECOREL FREE JP32

Is a SAC305 solder paste, especially designed to work on jet printing equipment and to guarantee continuous and consistent deposits of solder paste. Although the flux is chemical inert, it is easy to clean with water or solvent based processes. It is optimized to be used on Mycronic, Vermes, Essemtec and Musashi jet printing equipment.

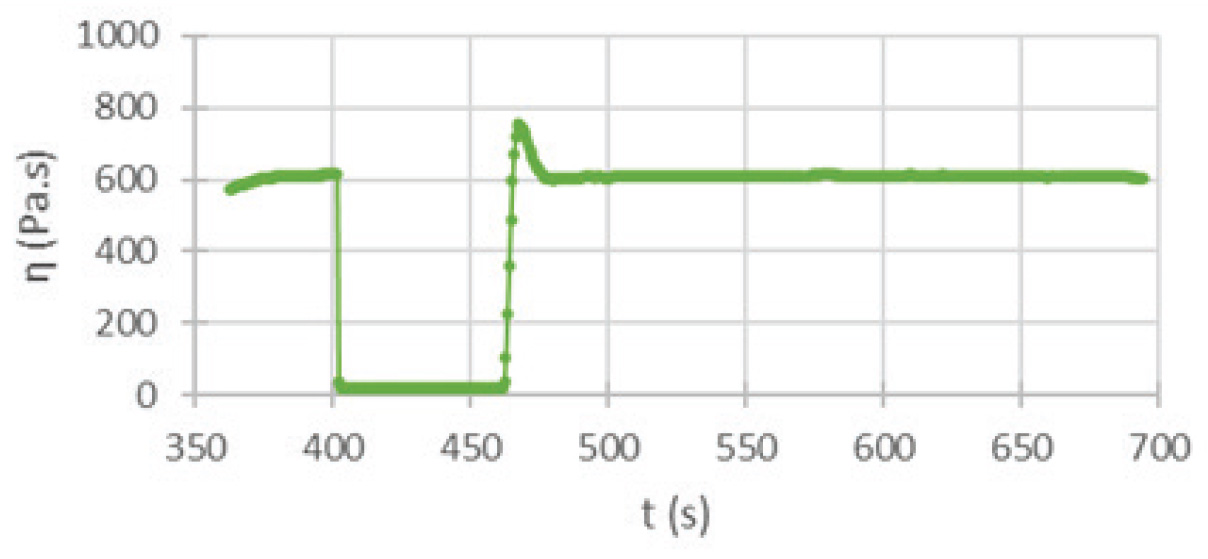

The graph represents our rheological measurement, which shows the very good thixotropic recovery of ECOREL FREE JP32. Stable viscosity recovery after a high shear stress on the solder paste guarantees consistent volume deposits.

| SPECIFICATIONS | ECOREL FREE JP32 84.0T5 | ECOREL FREE JP32 85.0T5 |

|---|---|---|

| Alloy | Sn96,5Ag3Cu0,5 | Sn96,5Ag3Cu0,5 |

| Melting point | 217°C/423°F | 217°C/423°F |

| Metal content (%) | 84 | 85 |

| Post reflow residues by w/w | Approximately 5% | Approximately 5% |

| Halogen content | No Halogen | No Halogen |

| Powder size | 15–25 microns / Type 5 | 15–25 microns / Type 5 |

| Spiral pump* Viscosity (Pa.s 25°C) | **Typical 90 | **Typical 90 |

| Syringe | Iwashita | EFD |

| Dedicated for equipment | Mycronic |

Vermes Essemtec Musashi |

*The equipment used to test spiral pump viscosity is Malcom at a 10 rpm rotation speed.

**Slight adjustments in viscosity possible after finalizing full industrialization test procedure.

| SPECIFICATIONS | ECOREL FREE JP32 84.0T6 | ECOREL FREE JP32 82.0T6 | ECOREL FREE JP32 80.0T6 | ECOREL FREE JP32 78.0T6 |

|---|---|---|---|---|

| Alloy | Sn96,5Ag3Cu0,5 | Sn96,5Ag3Cu0,5 | Sn96,5Ag3Cu0,5 | Sn96,5Ag3Cu0,5 |

| Melting point | 217°C/423°F | 217°C/423°F | 217°C/423°F | 217°C/423°F |

| Metal content (%) | 84 | 82 | 80 | 78 |

| Post reflow residues by w/w | Approximately 5% | Approximately 5% | Approximately 5% | Approximately 5% |

| Halogen content | No Halogen | No Halogen | No Halogen | No Halogen |

| Powder size | 5–15 microns / Type 6 | 5–15 microns / Type 6 | 5–15 microns / Type 6 | 5–15 microns / Type 6 |

| Spiral pump* Viscosity (Pa.s 25°C) | **Typical 90 | **Typical 90 | **Typical 90 | **Typical 90 |

| Syringe | Iwashita | EFD | EFD | EFD |

| Dedicated for equipment |

Mycronic Musashi |

Vermes Essemtec Musashi |

Vermes Essemtec Musashi |

Vermes Essemtec Musashi |

*The equipment used to test spiral pump viscosity is Malcom at a 10 rpm rotation speed.

**Slight adjustments in viscosity possible after finalizing full industrialization test procedure.

| CHARACTERISTICS | VALUES | TEST METHOD |

|---|---|---|

| Flux Classification | ROL0 | ANSI/J-STD-004 |

| 113 | ISO 9454 | ISO 9454 |

| Solder balling test | Pass | ANSI/J-STD-005 |

| Copper mirror | Pass | ANSI/J-STD-004 |

| Copper corrosion | Pass | ANSI/J-STD-004 |

| SIR (IPC) | Pass | ANSI/J-STD-004 |

This is not a product

Although fully in line with safety & environmental regulations, this product doesn`t match our strict criteria to be labelled as a Greenway product.

LOOKING FOR A MORE SUSTAINABLE SOLUTION?

GREENWAY ALTERNATIVE

- We currently don`t have a Greenway alternative but our target is to develop one in the near future. In case you want us to prioritize the development of a Greenway alternative, do not hesitate to contact us.

Benefits

Performance

- Excellent continuous & consistent paste deposits

- Chemical inert flux residue reducing risk of electrochemical migration & corrosion

- Easy to clean reflowed flux residues

COST

- Minimizes line-down time & the need for re-work

- Increase lifetime and reliability of your product, hence reduces risk of premature failures

HSE

- No Halogen

- Lead Free

- Free of CMR containing substances