ECOFREC 303E

Low-residue, VOC-free soldering flux

- Water-based no-clean liquid flux

- Wave & selective soldering

- Excellent wetting & High electronic reliability

ECOFREC 303E

Is a low-residue, no-clean, VOC-free flux designed for wave and selective soldering. It is based on our legacy product ECOFREC 303, offering enhanced wetting performance while maintaining exceptionally low residue levels.

Thanks to its high SIR values, cleaning before applying compatible conformal coatings is generally unnecessary.

FEATURES

| SPECIFICATIONS | ECOFREC 303E |

|---|---|

| Appearance | Colorless liquid |

| Solid content (%) | 3.5 |

| Acid index (mg KOH/g) | 32 |

| Density at 20°C | 1.005 – 1.013 |

| Halogen content | No halogen |

| Flash point | No |

CHARACTERISTICS

| CHARACTERISTICS | VALUES | METHOD |

|---|---|---|

| Flux Classification | ORL0 | ANSI/J-STD-004 |

| Copper mirror | Pass | ANSI/J-STD-004 |

| Chromate paper | Pass | ANSI/J-STD-004 |

| SIR (IPC) | Pass | ANSI/J-STD-004 |

| Bono Corrosion test (85°C / 85% HR – 15 days) | Pass / Corrosion Factor = 1.1% | Inventec procedure |

This is a product

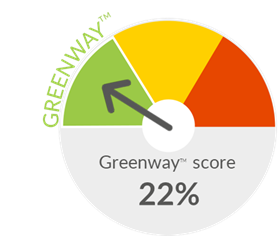

MAIN CONTRIBUTORS WHICH REDUCE IMPACT:

HUMAN HEALTH & SAFETY

- Non-flammable, no flashpoint

- Non-toxic & low corrosive impact

ENVIRONMENT PROTECTION & RESOURCES SAVINGS

- Made from biobased dicarbon acid

- No environmental hazard: no H labelling regarding environment

- High reliability formulation (pass BONO test)

- No-clean formulation, minimizes the need for post reflow cleaning

Benefits

PERFORMANCE

- Great performance for Ni/Au, Sn, Ag, HAL and OSP PCB finishes

- Very low flux spreading

- Exceptionally low levels of solder-ball formation

- High SIR values and passes BONO corrosion test

- Excellent pin-point testability

COST

- Helps to avoid pre-mature failures of your electronic assembly

- No-clean formulation minimizing cleaning needs

- Minimized storage and shipment costs – non-DG material

- Suitable for Non explosion-protected equipment

HSE

- Free of halide (Fluoride, Chloride, Bromide) and halogen

- Free of CMR containing substances

- Non-VOC formulation

- Greenway product

Process Recommendation

The best process will depend on factors such as operating conditions, equipment, board or component design. Check our product datasheet for info on process recommendations. In any case, our team is ready to advise and assist you in the implementation of our products.