Solder Paste Repair Solutions

Our full-range offering of advanced solder paste repair solutions is designed to deliver precision, reliability, and efficiency in rework soldering, ensuring high-quality solder repair for today’s complex electronic assemblies.

Precision Repair with Advanced Solder Paste Solutions for Electronics Rework

Advanced solder paste repair solutions are essential in the rework and restoration of complex electronic assemblies. These solutions are specifically engineered for precise application and reliable results on high-density packages like BGAs (Ball Grid Arrays) and QFNs (Quad Flat No-leads).

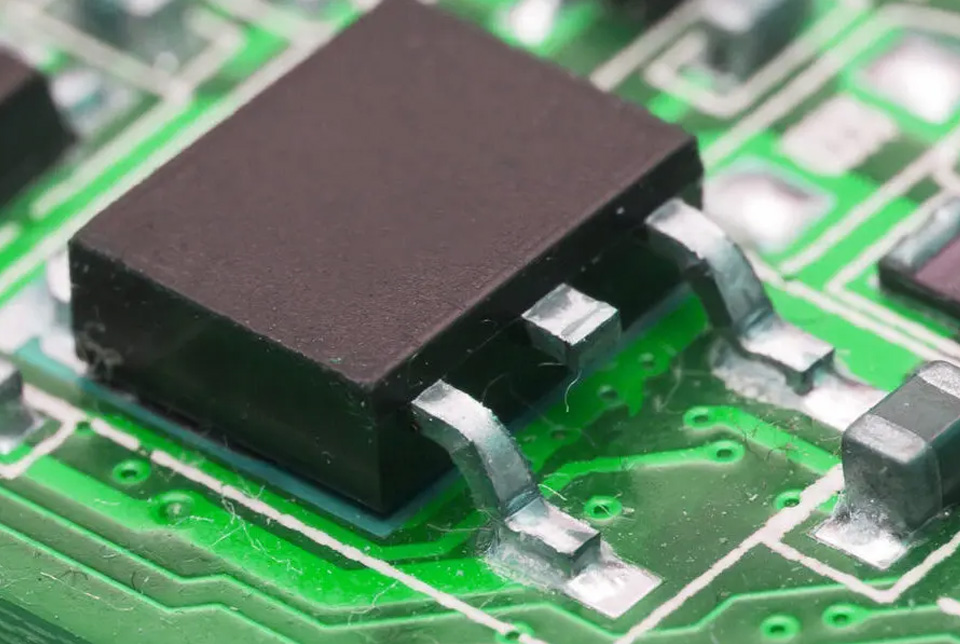

At the heart of this method lies high-performance solder paste, a blend of flux and solder powder that delivers exceptional reflow characteristics. Applied directly to the target joint, the paste enables technicians to execute controlled reflow processes that restore electrical integrity and mechanical durability.

These repair solutions are ideal for rework soldering in limited-access areas, providing strong adhesion, improved solder wetting, and minimal residue. Convenient syringe packaging enhances precision and ease of application, making solder paste repair both accurate and efficient.

Key Benefits of Solder Paste Repair Solutions:

- Restores faulty solder joints on BGAs, QFNs, and SMDs with high accuracy

- Enables precise reflow with minimal thermal stress and maximum joint integrity

- Combines tacky and liquid flux characteristics for optimal solder flow

- Available in syringe format for targeted, user-friendly application

INVENTEC offers a full range of solder paste repair solutions optimized for rework efficiency and long-term performance in electronics manufacturing.

See Other Repair Solutions Read FAQ

Read moreDiscover Our Halogen-Free No-Clean Tacky Flux for All Your Soldering Needs!

ECOFREC TF49

- Halogen free tacky flux

- Flip Chip & Rework soldering

- Low residue properties

Solder Paste

Rework & Repair Soldering Solutions

Frequently Asked Questions (FAQ)

What are solder paste repair solutions?

Solder paste repair solutions involve using specially formulated solder pastes designed for reworking, repairing, or touch-up of printed circuit boards (PCBs) and components. These pastes enable precise solder deposition and reliable joint formation during repair processes.

How do solder paste repair solutions differ from solder flux repair solutions?

While solder flux focuses on cleaning and activating surfaces to promote wetting, solder paste contains both flux and solder alloy particles, enabling it to form new solder joints directly. Paste is ideal for rebuilding pads, filling gaps, or replacing components.

What types of solder paste are used for repair?

Repair solder pastes are often low-voiding, no-clean, or water-soluble types formulated for excellent tackiness and fine pitch compatibility. INVENTEC offers repair pastes optimized for rework applications, including lead-free alloys like SAC305.

Can solder paste repair solutions be applied manually?

Yes. Repair solder pastes can be applied manually using syringes, dispensing systems, or stencil printing for precise placement during PCB rework or component replacement.

How important is solder paste viscosity and tackiness in repair applications?

Viscosity and tackiness affect paste handling and component placement. Properly formulated repair pastes provide consistent viscosity for easy dispensing and enough tack to hold components in place before reflow.

Are solder paste repair solutions compatible with lead-free soldering?

Yes, INVENTEC’s solder paste repair solutions are fully compatible with lead-free soldering processes, ensuring strong, reliable joints that meet RoHS and environmental standards.

What reflow profiles are recommended for solder paste repair?

Optimized reflow profiles with controlled temperature ramps and soak zones ensure complete solder alloy melting and flux activation, minimizing defects and promoting strong solder joints during repair.

How does solder paste repair improve PCB assembly yield?

By enabling precise rework and defect correction without replacing entire boards, solder paste repair reduces scrap rates, saves costs, and enhances overall manufacturing yield.

What challenges exist in solder paste repair?

Challenges include ensuring pad adhesion, preventing bridging, and matching solder alloy composition. High-quality solder paste formulations like INVENTEC’s help overcome these challenges with consistent performance.

Does INVENTEC offer solder paste repair products?

Yes, INVENTEC Performance Chemicals provides a range of solder paste repair solutions tailored for manual and automated rework processes, supporting lead-free and high-reliability electronic manufacturing.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

Do you need cleaning or coating after soldering? We provide FREE-OF-CHARGE cleaning or coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. It is also possible to attend trials in person.