Miniaturization Solder Paste Solutions

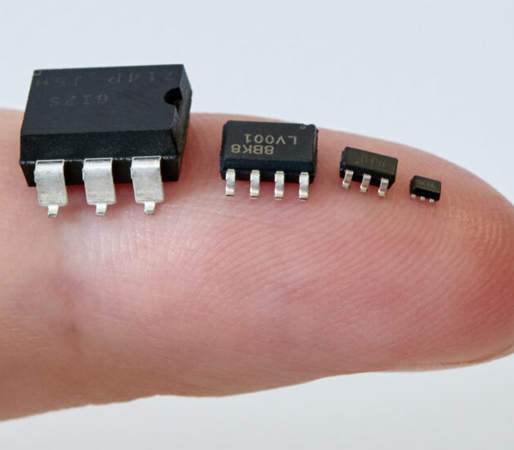

Advanced Miniaturization Solder Paste Solutions, including ultra-fine T4, T5, and T6 formulations, are driving innovation in SMT by enabling precise and reliable assembly of ever-smaller electronic components for next-generation devices.

Driving Innovation in SMT with Ultra-Fine SMT Solder Paste for the Miniaturization Challenge

With the continued miniaturization of electronic components, today’s electronics manufacturers face increasing pressure to deliver high-density assemblies with precision, speed, and reliability. From smartphones to IoT wearables, miniature electronic devices demand solder pastes capable of handling extremely fine pitches and reduced pad sizes without sacrificing joint integrity.

INVENTEC addresses this challenge with advanced SMT solder paste formulations utilizing ultra-fine powder technology. While our standard line features T4 solder paste, we also offer high-performance T5 and T6 solder paste options tailored for ultra-fine pitch and micro-component placement.

These specialized miniaturization solder paste solutions are ideal for manufacturers building the next generation of compact electronics—such as mobile devices, advanced sensors, and space-constrained medical or industrial systems.

Key Features of INVENTEC Miniaturization Solder Paste:

- Ultra-fine T4, T5, and T6 powder sizes for fine-pitch SMT applications

- Superior printability and paste release on miniaturized pad geometries

- Enhanced wetting and joint integrity for dense, complex board layouts

- Customizable alloy and flux combinations via ECOREL™ technology

- Perfect for mobile, wearable, IoT, and medical device manufacturing

Whether you’re scaling down devices or innovating next-gen electronics, INVENTEC’s ultra-fine SMT solder paste solutions deliver the precision and consistency required for advanced miniaturization challenges.

See Other SMT Solder Paste Processes Read FAQ

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Showing all 4 results

-

-

-

ECOREL EASY SPA-15

- SnPbAg leaded solder paste

- No clean SMT printing process

- Excellent performance for ultrafine-pitch

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

Discover our Ultra-Fine Pitch Solder Paste—Perfect for Miniaturized Devices!

ECOREL EASY SPA-15

- SnPbAg leaded solder paste

- No clean SMT printing process

- Excellent performance for ultrafine-pitch

Miniaturization

Solder Paste Solutions

Frequently Asked Questions (FAQ)

What are miniaturization solder paste solutions?

Miniaturization solder paste solutions are advanced formulations designed for high-precision soldering in miniature electronic assemblies. These pastes offer excellent print definition, controlled viscosity, and reliable performance for fine-pitch components and ultra-small pad sizes used in modern compact devices.

Why is specialized solder paste needed for miniature components?

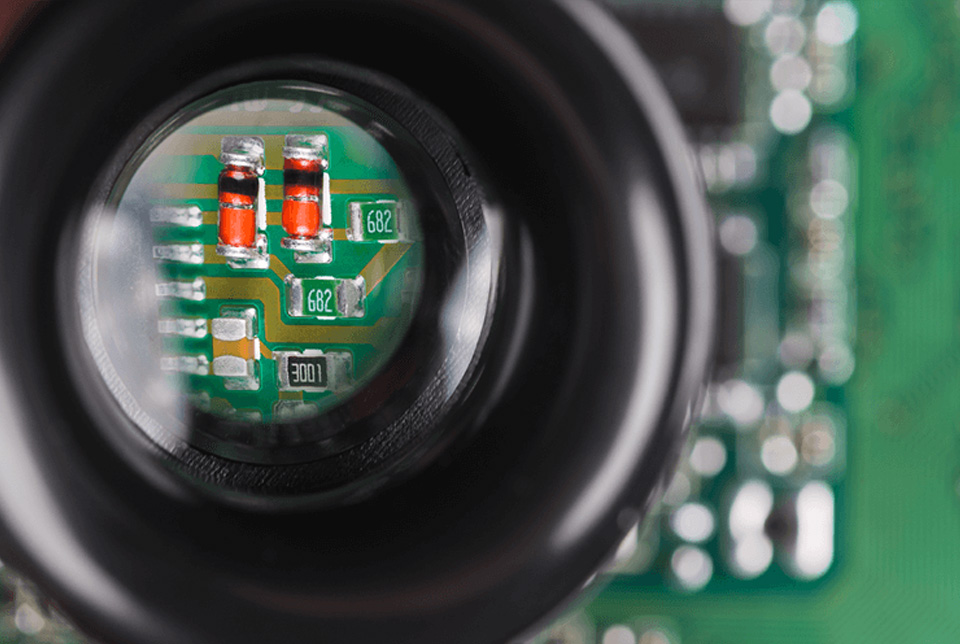

Miniature components such as 01005 chips, micro BGAs, and CSPs require extremely precise solder deposition to avoid bridging, insufficient solder, or placement errors. Standard solder pastes may lack the rheology or particle size control needed for such high-density designs.

What key properties are important in solder pastes for miniaturized electronics?

Important properties include fine-tuned viscosity, excellent slump resistance, low residue, and fine Type 5 or Type 6 powder distribution. These characteristics ensure accurate deposition, sharp stencil definition, and consistent solder joint formation for high-density PCBs.

What printing technologies are used with miniaturization solder pastes?

Miniaturization solder pastes are compatible with high-precision stencil printing and jet dispensing systems. These techniques ensure consistent solder volume and placement accuracy, critical for soldering ultra-small pads without defects.

Are there specific alloys used for miniaturization soldering?

Commonly used alloys include SAC305 and low-silver or no-silver lead-free variants, often in Type 5 or Type 6 powder grades. INVENTEC Performance Chemicals offers such alloys optimized for high-resolution printing and miniature component reliability.

What are the challenges of soldering miniaturized electronic devices?

Challenges include managing solder paste volume, avoiding bridging and tombstoning, ensuring full reflow under tight component spacing, and achieving consistent joint quality across very small pads. High-quality solder pastes and process control are essential to overcome these issues.

How does miniaturization solder paste impact reflow profile settings?

Miniaturized assemblies often require tighter thermal profiles to avoid damaging sensitive components or causing thermal warping. Miniaturization solder pastes are engineered for stable reflow behavior and fast wetting at controlled temperatures, enabling safer processing.

Is there a risk of voiding or residue with fine-pitch soldering?

Yes, due to tighter pad spacing and lower solder volumes, voiding or flux residue can more easily impact performance. Miniaturization solder pastes are designed to leave minimal residues and reduce void formation, supporting reliability in dense electronic assemblies.

Which industries benefit most from miniaturization solder paste solutions?

Industries such as wearables, smartphones, medical electronics, IoT devices, aerospace, and telecom benefit significantly. These sectors demand compact, lightweight designs with uncompromising performance and high soldering precision.

Does INVENTEC offer solder pastes for miniaturized electronic assemblies?

Yes. INVENTEC Performance Chemicals provides specialized solder pastes engineered for miniaturization, including fine-powder alloys and ultra-precise printing formulations. These solutions support next-generation electronics manufacturing with excellent print quality and joint reliability.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

Do you need cleaning or coating after soldering? We provide FREE-OF-CHARGE cleaning or coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. It is also possible to attend trials in person.