Jet Printing & Dispensing Solder Paste Solutions

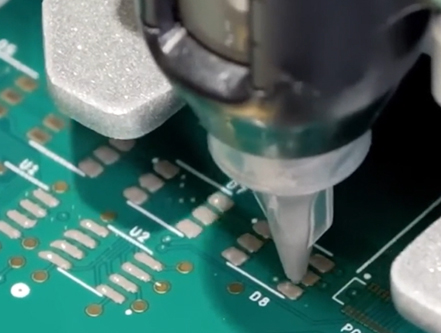

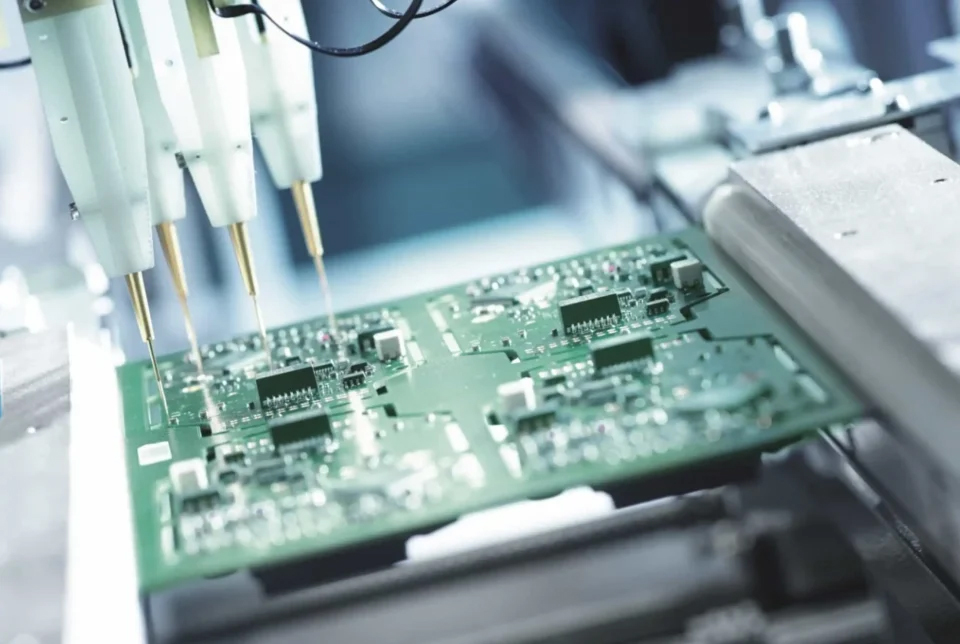

Our dedicated offer of advanced jet printing solder paste and dispensing solder paste solutions optimized for high-performance jet dispensing and dispensing systems, ensuring precision, reliability, and flexibility in modern electronic assembly.

Jet Printing & Dispensing Solder Paste Solutions for Precision Electronics

INVENTEC’s jet printing and dispensing solder paste solutions are engineered for contactless, high-precision application in advanced electronics assembly, including SiP, SMT, and LED manufacturing.

Our formulations ensure exceptional print quality, dot consistency, and process stability across a wide range of platforms such as Mycronic, Vermes, and Essemtec—making them ideal for miniaturized PCBs and fine-pitch components.

Whether using high-speed jetting systems or traditional needle dispensers, INVENTEC offers reliable solder paste technologies optimized for deep cavities, irregular geometries, and high-mix production environments.

Key Advantages of Jet Printing & Dispensing Solder Pastes:

- Non-contact, high-speed solder paste application for fine-pitch designs

- Compatible with major jet and needle dispensing systems

- Accurate dot placement and consistent solder volume control

- Easy post-process cleaning with both water- and solvent-based options

INVENTEC’s jet and dispensing solder pastes ensure high reliability and flexibility for next-gen electronic assembly lines worldwide.

See Other SMT Solder Paste Processes Read FAQ

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Showing all 3 results

-

-

-

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us

Discover our Jet printing equipment solder paste!

ECOREL FREE JP32

- SAC305 solder paste

- Jet printing process

- Easy cleanable flux residues

Jet Printing & Dispensing

Solder Paste Solutions

Frequently Asked Questions (FAQ)

What is jet printing solder paste in industrial soldering?

Jet printing solder paste is an automated, non-contact method of applying solder paste droplets directly onto PCB pads using a high-precision jetting nozzle. This process improves accuracy and reduces material waste compared to traditional stencil printing, especially for fine-pitch components and complex PCB layouts.

How does solder paste dispensing differ from jet printing?

Solder paste dispensing typically uses pneumatic or mechanical syringes to deposit controlled amounts of paste in specific locations. While dispensing is slower and contact-based, jet printing is non-contact and capable of higher throughput, making it suitable for high-volume, fine-pitch applications.

What are the main advantages of jet printing solder paste?

Key advantages include precise paste volume control, minimal solder paste waste, elimination of stencil use, and the ability to quickly change pad patterns via software. This flexibility is ideal for prototyping, low-to-medium volume production, and complex PCB designs.

Which solder pastes are compatible with jet printing technology?

Jet printing requires solder pastes with optimized rheology and particle size distribution to prevent clogging and ensure consistent droplet formation. INVENTEC Performance Chemicals offers specially formulated solder pastes designed for jet printing and dispensing processes, ensuring reliability and print quality.

Can jet printing solder paste handle high-volume industrial production?

Yes, modern jet printing systems have been developed for industrial environments, offering high-speed and repeatable solder paste deposition. While stencil printing remains dominant for very high volumes, jet printing is increasingly adopted for medium volumes, rapid changeovers, and advanced package types.

What industries benefit most from jet printing solder paste solutions?

Industries such as aerospace, automotive electronics, medical devices, and telecommunications benefit from jet printing due to its precision, flexibility, and ability to handle complex PCB assemblies with fine-pitch components and varying board designs.

How does jet printing impact solder joint quality?

Properly optimized jet printing processes provide consistent solder paste deposition, leading to uniform solder joints with minimal defects such as bridging or insufficient solder volume. Using compatible solder paste formulations from providers like INVENTEC helps maintain high joint reliability.

What maintenance is required for jet printing solder paste systems?

Regular nozzle cleaning and inspection are critical to prevent clogging and maintain droplet accuracy. Additionally, monitoring paste viscosity and storage conditions ensures optimal print performance and minimizes downtime in industrial soldering lines.

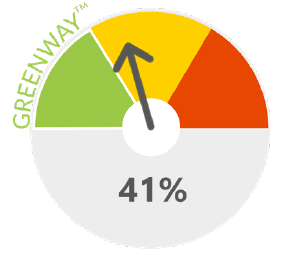

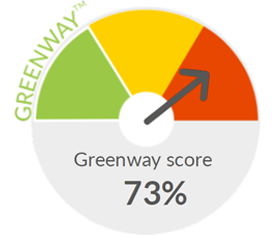

How does jet printing solder paste contribute to sustainability?

By reducing solder paste waste and eliminating stencil cleaning chemicals, jet printing supports environmentally friendly manufacturing. Combined with INVENTEC’s environmentally conscious solder paste formulations, this technology aligns with modern green manufacturing initiatives.

Where can I find more information about INVENTEC’s jet printing solder paste solutions?

INVENTEC Performance Chemicals provides advanced solder paste formulations optimized for jet printing and dispensing. Visit their official website to explore technical datasheets, application notes, and product options designed for industrial soldering excellence.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

Do you need cleaning or coating after soldering? We provide FREE-OF-CHARGE cleaning or coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. It is also possible to attend trials in person.