Maintenance Cleaning

Our full range of maintenance cleaning solutions for electronics and semiconductor applications is designed to deliver precision, reliability, and efficiency, ensuring thorough cleaning that boosts equipment performance and minimizes production downtime.

Optimizing Performance with Effective Maintenance Cleaning for Electronics & Semiconductors

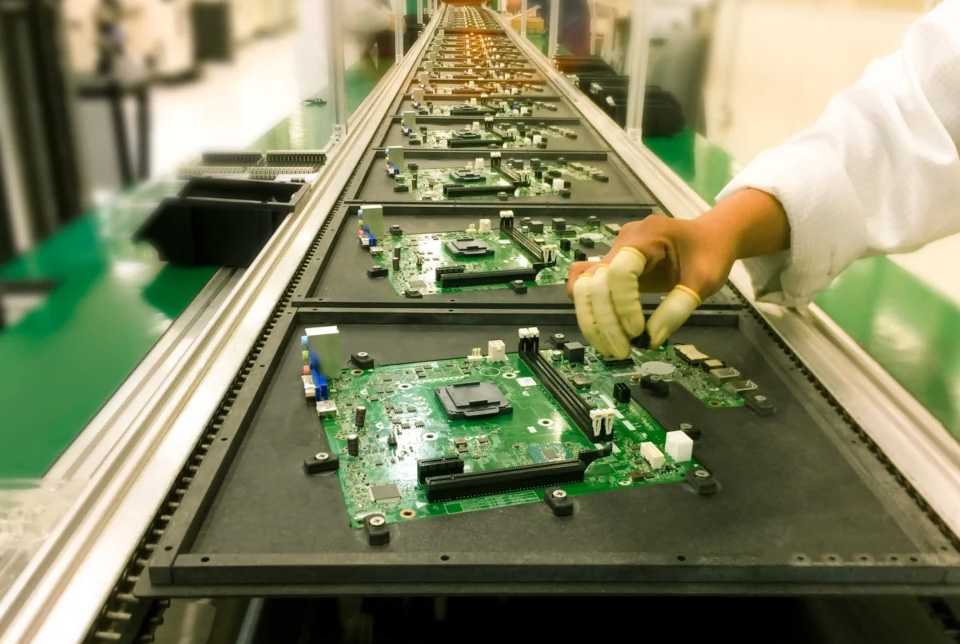

Effective maintenance cleaning is vital in semiconductor and electronics manufacturing to maximize equipment lifespan, reduce downtime, and ensure a reliable production process. Neglecting regular cleaning can lead to decreased efficiency and costly interruptions.

Typical contaminants such as burnt-in flux, condensed gas emissions, and coatings accumulate on equipment surfaces, frames, pallets, and conveyors. Specialized electronics cleaning solutions—especially for delicate components like dispensing needles—are essential to maintain production accuracy and integrity.

INVENTEC’s maintenance cleaning products are designed for fast, efficient cleaning with minimal downtime, prioritizing operator safety and environmental sustainability by using low-hazard, eco-friendly formulations that support your company’s clean production goals.

Key Benefits of Maintenance Cleaning Solutions

- Fast, effective cleaning solutions for semiconductor manufacturing equipment

- Removes burnt-in flux, gas condensates, and other common contaminants

- Specialized formulations for sensitive parts such as dispensing needles

- Low hazard and environmentally sustainable cleaning products

INVENTEC provides advanced maintenance cleaning products to ensure uninterrupted production and high reliability in semiconductor and electronics manufacturing environments.

Explore More Cleaning Solutions Read FAQ

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Showing all 3 results

-

-

-

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us

Discover our powerful flux residue remover for sensitive electronics cleaning!

PROMOCLEAN DISPER 610

- Removal baked-on flux residues

- Aqueous spray process

- Compatible with aluminium

This is a product

Maintenance

Electronic & Semiconductor Cleaning Solutions

Frequently Asked Questions (FAQ)

What is maintenance cleaning in electronics and semiconductor manufacturing?

Maintenance cleaning involves regular cleaning of production equipment, tools, and work areas to prevent contamination buildup that could affect product quality and process reliability.

Why is maintenance cleaning important in electronics manufacturing?

Routine maintenance cleaning reduces risks of defects caused by dust, flux residues, and particulate contamination, ensuring consistent yields and prolonging equipment life.

What areas are typically targeted during maintenance cleaning?

Cleaning focuses on soldering equipment, stencil printers, conveyor belts, robotic arms, and work surfaces to minimize cross-contamination and maintain process cleanliness.

Which cleaning agents are used for maintenance cleaning?

Specialized cleaning solutions from INVENTEC are designed to safely and effectively remove flux residues, oils, and particulates without damaging sensitive equipment components.

How often should maintenance cleaning be performed?

The frequency depends on production volume, process type, and equipment usage, but typically ranges from daily to weekly to ensure optimal performance.

Can maintenance cleaning prevent equipment downtime?

Yes. Regular cleaning helps avoid equipment malfunctions, prolongs service intervals, and minimizes unexpected downtime caused by contamination-related failures.

Are maintenance cleaning procedures automated?

Some cleaning tasks can be automated, such as stencil cleaning systems, while others require manual intervention. INVENTEC supports both manual and automated cleaning solutions.

How is the effectiveness of maintenance cleaning verified?

Inspection methods include visual checks, residue testing, and equipment performance monitoring to ensure cleanliness levels meet required standards.

Are there environmental concerns with maintenance cleaning chemicals?

Cleaning agents should be low in VOCs, biodegradable, and compliant with environmental regulations. INVENTEC emphasizes eco-friendly formulations to support sustainable manufacturing.

Does INVENTEC offer products for maintenance cleaning?

Yes, INVENTEC Performance Chemicals provides a comprehensive portfolio of cleaning agents tailored for maintenance cleaning in electronics and semiconductor production environments.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.