Diamond Polishing Slurry Removal

Our advanced diamond polishing slurry removal solutions are engineered for precise, efficient elimination of abrasive residues, ensuring flawless surface integrity, enhanced component longevity, and optimal preparation for final finishing processes in critical polishing environments.

Efficient Diamond Polishing Slurry Removal for High-Precision Cleaning in Hard Material Machining

Removing stubborn residues of diamond polishing slurry and other diamond polishing compounds from precision-machined parts is a critical challenge that demands advanced, high-performance cleaning solutions.

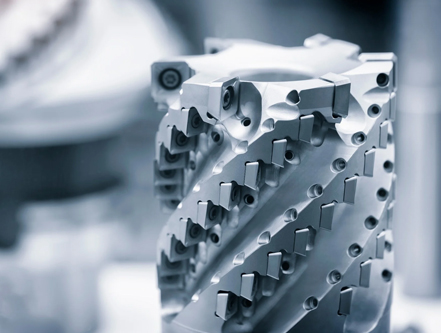

The machining and polishing of ultra-hard materials—such as tungsten carbide cutting tools and precision components—often rely on advanced abrasives like diamond polishing slurry, diamond compound, and diamond polishing paste. These abrasive solutions are essential for achieving high-precision finishes, especially in demanding industrial sectors such as aerospace, automotive, and medical device manufacturing.

However, the use of diamond polishing compounds presents a critical challenge: their ultra-fine particles and sticky consistency can lodge deep into the pores and cavities of metal surfaces. This makes thorough cleaning both technically demanding and essential to avoid contamination or part failure. A reliable and repeatable cleaning process is crucial, especially in fast-paced, high-volume production lines.

| Type of Pollutant | Type of Process | Product Solution |

|---|---|---|

| Diamond polishing slurry | Aqueous immersion cleaning with acidic detergents |

|

Key Benefits of Diamond Polishing Slurry Removal Solutions:

- Exceptional cleaning performance, even in components with high porosity and complex geometries

- Long-lasting bath life that supports continuous, high-throughput production processes

- Compliance with strict environmental regulations and sustainable manufacturing practices

INVENTEC’s industrial cleaning systems are engineered to deliver reliable, residue-free results for diamond polishing slurry and diamond compound residues, enhancing product quality and operational efficiency.

See Other Polishing Removal Processes Read FAQ

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Showing all 2 results

-

PROMOCLEAN TP 178

- Removing oxides, mineral residues & diamond liquid polishing

- Aqueous immersion process with ultrasonics

- Substitute for phosphoric acid based cleaners

-

TOPKLEAN MC 1007D

- Heavy contaminants removal

- Mono-solvent, co-solvent or spray process

- Environmental friendly alternative to perchlorethylene & nPB

Discover Our Advanced Solution for Heavy-Duty Precision Cleaning!

TOPKLEAN MC 1007D

- Heavy contaminants removal

- Mono-solvent, co-solvent or spray process

- Environmental friendly alternative to perchlorethylene & nPB

Diamond Polishing Slurry Removal

Industrial Cleaning Solutions

Frequently Asked Questions (FAQ)

What is the diamond polishing slurry removal process?

The diamond polishing slurry removal process involves using specialized solutions to efficiently eliminate residual polishing compounds, including diamond abrasives, from metal or plastic surfaces. This ensures clean, defect-free surfaces ready for final finishing or assembly.

Why is removing polishing residues important?

Residual polishing compounds can interfere with surface quality, affect coatings or adhesion, and reduce component longevity. Complete removal improves reliability, enhances surface integrity, and prepares components for subsequent processing.

Which types of surfaces can be treated?

Diamond polishing slurry removal solutions are suitable for a variety of metals and hard plastics, including stainless steel, aluminum, brass, and high-performance polymers, depending on the required process and desired surface finish.

How do these solutions ensure precision and efficiency?

Advanced formulations are designed to dissolve or suspend abrasive particles without damaging the underlying surface. Correct process parameters help maintain consistency, reduce manual cleaning, and minimize the risk of defects.

Are these solutions compatible with automated cleaning systems?

Yes. Many diamond polishing slurry removal solutions, including those developed by INVENTEC Performance Chemicals, are engineered for compatibility with ultrasonic baths, spray systems, or immersion cleaning equipment, enabling efficient and repeatable results.

How do I ensure component safety during the process?

Always follow recommended concentrations, exposure times, and rinsing protocols. Proper handling prevents surface damage and ensures thorough removal of abrasive residues while maintaining component integrity.

Can these solutions be environmentally friendly?

Modern diamond polishing slurry removal solutions are designed to reduce hazardous waste, minimize environmental impact, and comply with industrial safety standards, making them safer for operators and the environment.

What are best practices for removing diamond abrasive residues?

Use precise timing, proper solution strength, and agitation techniques to ensure diamond particles are fully suspended and rinsed away. Monitoring the process can prevent scratches or surface defects.

How can the process be optimized for different polishing stages?

Adjust solution concentration, temperature, and exposure duration based on the type of polish, substrate, and desired surface finish. Testing on sample components helps determine the most effective parameters.

Where can I find more information about diamond polishing slurry removal solutions?

INVENTEC Performance Chemicals provides detailed technical data sheets, application guidance, and support for advanced diamond polishing slurry removal processes in critical industrial polishing applications.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.