THERMASOLV WB1

Heat transfer fluid for pure performance and safer cooling

- Heat transfer fluid

- Boiling point: 111°c/232°f

- Renewable plant based fluid

THERMASOLV WB1

Is a renewable plant-based heat transfert fluid (1,3-propanediol and corrosion inhibitors), dedicated for industrial process chillers or direct plate or tube cooling systems.

It is a biodegradable fluid that meets OECD criteria extrapolated to a finished products, achieving 90% to 100% biodegradation within 28 days. With its chemical stability and lower viscosity, THERMASOLV WB1 offers an excellent alternative to traditional monopropylene glycol (MPG) fluids.

THERMASOLV WB1 exhibits excellent water stability and is formulated with safety in mind. It is non-toxic, non-flammable and has no flash point. The anti-corrosive H-OAT (neutralised carboxylic acids) formulation is nitrite and amine free.

This heat transfer fluid shows very good compatibility with all metals as well as a wide range of plastics & elastomers.

| SPECIFICATIONS | VALUES | METHODS |

|---|---|---|

| Aspect | Green liquid | Visual |

| Density @ 20°C | 1.053 | AFNOR NF R 15-602-1 / ASTM D 1222 |

| CHARACTERISTICS | VALUES |

|---|---|

| Flash point | No |

| Boiling point @ atmospheric pressure | 111°C/232°F |

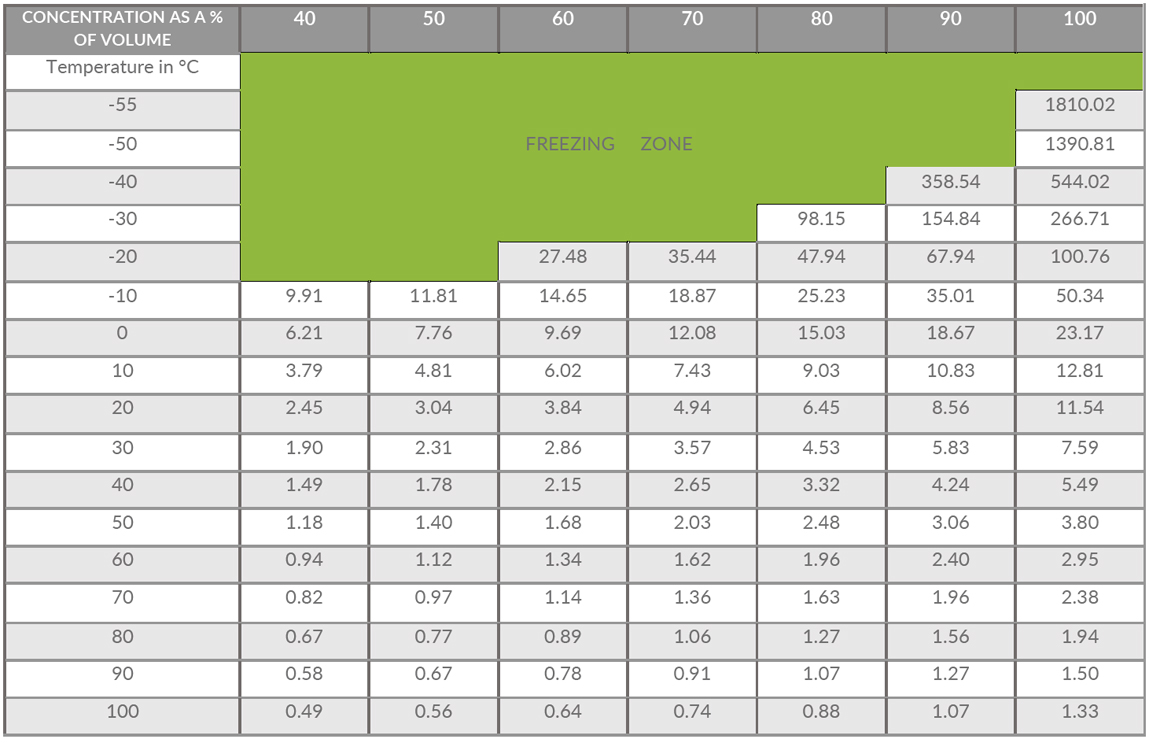

| Freezing point | -55°C/-67°F |

| Solubility in water | Total |

| Atmospheric lifetime (90%-100% biodegraded) | 28 days |

| Kinematic Viscosity (cSt) @20°C | 11.54 |

| Specific Heat (kJ/Kg/K) @20°C | 2.753 |

| Thermal Conductivity (W/m·K) @20°C | 0.320 |

This is a product

MAIN CONTRIBUTORS WHICH REDUCE IMPACT:

HUMAN HEALTH & SAFETY

- Non-flammable, no flashpoint & no EUH risk phrases: 100% safe for storage and when used in equipment

- Non-toxic, no corrosive impact & no S risk phrases

- Contains vegetable based raw materials

ENVIRONMENT PROTECTION & RESOURCES SAVINGS

- No environmental hazard: no H labelling regarding environment

- Ultra-low GWP (1-30)

Benefits

Performance

- Excellent thermal conductivity and water stability

- Excellent protection against freezing & deposition in the system

- Lower viscosity than traditional MPG

- Bacteriostatic (according to ISO11930) action avoids bacteriologic development which affectsthe flow & heat exchange in materials

Cost

- Concentrated product, ready to dilute in water, saving on transport & storage cost

HSE

- Low environmental impact: GREENWAY product

- Nontoxic

- Biodegradable according to the OECD. Biodegrades 90%-100% in 28 days

- Based on renewable raw materials

- Non-flammable & no flashpoint

Process information

Processes

The best process will depend on factors such as operating conditions & equipment. Our team is ready to advise you.

We recommend preparing the THERMASOLV WB1 solution with DI water, at a minimum concentration of 40% by volume for optimum protection against corrosion before filling your installation. The product can be used in the following processes:

- Direct to chip cooling, where the fluid flows through cold plates or tubes (only 1-phase)

- ndustrial process chillers

- Specific manufacturing processes which need stable and uniform cooling