THERMASOLV CF3

Dielectric Cooling Fluids for electronic & electric devices

- Dielectric heat transfer fluid

- Boiling point: 120°C/248°F

- Non-flammable & low GWP

THERMASOLV CF3

Is a dielectric heat transfer fluid, dedicated for 1-phase immersion or direct cooling systems. Its high electrical insulation properties allows to immerse electronics & electrical devices under power in the fluid. The favorable characteristics of the product’s viscosity, density and surface tension allows optimal surface contact, which contributes to a superior heat transfer performance.

The very good compatibility with all metals, a wide range of plastics & elastomers and the chemical stability of the fluid, makes THERMASOLV CF3 an ideal fluid for immersion cooling.

The chemical nature of THERMASOLV CF3 makes it also a suitable product as a tacky agent for preform die-attach soldering process. It is easy to spray and leaves no residues after evaporation in the reflow step.

THERMASOLV CF3 is formulated with safety in mind. It is non-toxic, has no mentioning of any EUH-phrases, is non-flammable and has no flash point. It is also a great sustainable solution as it has no ODP, low GWP and can be offered for recycling when needed.

| SPECIFICATIONS | VALUES | METHODS |

|---|---|---|

| Aspect | Colorless, clear | Visual |

| Purity (%) | >99.5 | Internal |

| CHARACTERISTICS | VALUES |

|---|---|

| Flash point | No |

| Boiling point | 120°C / 248°F |

| Pour Point | -82°C / -116°F |

| Critical Temperature | 285°C / 545°F |

| Critical Pressure (MPa) | 4.28 |

| Vapor pressure (kPa @20°C) | 1.5 |

| Heat of vaporization (kJ/kg @BP) | 82.8 |

| Liquid density (kg/m³ @20°C) | 1836 |

| Kinematic viscosity (cSt @20°C) | 1.27 |

| Specific Heat (J/kg·K @25°C) | 1034 |

| Surface tension (dynes/cm²) | 13 |

| Dielectric strength (kV) | >35.7 |

| Dielectric Constant @1 kHz | 2.09 |

| Resistivity (Ohm·cm) | >1.00E+15 |

| Thermal conductivity (W/m·K) | 0.064 |

| Water content spec (ppm) | 15 |

| Solubility of water in fluid (ppm weight) | <10 |

This is a product

MAIN CONTRIBUTORS WHICH REDUCE IMPACT:

HUMAN HEALTH & SAFETY

- Non-flammable, no flashpoint & no EUH risk phrases: 100% safe for storage and when used in equipment

- Non-toxic, no corrosive impact & no S risk phrases

ENVIRONMENT PROTECTION & RESOURCES SAVINGS

- No environmental hazard: no H labelling regarding environment

- Can be returned for recycling and re-use: ECOPROGRAM

- Low viscosity: reduced energy use for pumps

Benefits

Performance

- Excellent thermal conductivity

- Very low surface tension

- High electrical insulation

- Low kinetic viscosity

Cost

- Thermally and chemically stable in use

- Can be returned for recycling and re-use

HSE

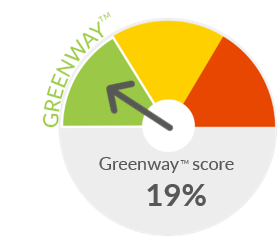

- Low Global Warming Potential (GWP): <108

- No Ozon depletion potential (ODP)

- Non-flammable & no flashpoint

- Low environmental impact: GREENWAY product

Process information

Processes

The best process will depend on factors such as operating conditions & equipment. Our team is ready to advise you.

Although this product has very good compatibility properties, we cannot foresee all materials that could be exposed to the fluid. We strongly recommend testing before use.

The product can be used in the following processes:

- Immersion cooling (only 1-phase)

- Direct cooling, where the fluid flows through cold plates or tubes (only 1-Phase)

- Specific manufacturing processes which need stable and uniform cooling

- Dielectric testing

- Tacky agent for preform die-attach soldering

Temperature limits

1-phase system

- Recommended Temperature Minimum: -65°C / -85°F

- Recommended Temperature Maximal: 110°C / 230°F